Large thrust ratio, long-working micro-ablation throat insert and throat structure of expansion section

A diffusion-stage, long-term technology, used in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems that the tail nozzle cannot meet the large thrust ratio, low ablation rate, total thrust loss, etc., and achieve good Insulation effect, the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

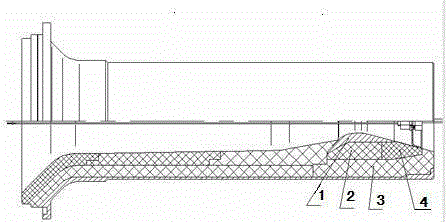

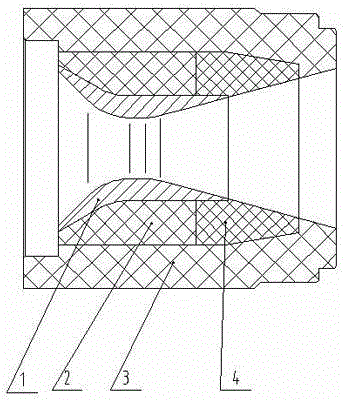

[0016] Now describe in detail the throat structure of a large thrust ratio, long-time working micro-ablation throat liner and diffuser section of the present invention.

[0017] In the components of the throat structure of a large thrust ratio, long-time working micro-ablation throat liner and the diffuser section of the present invention, the throat liner 1, the back liner 2, the bottom liner 3 and the heat insulation layer 4 of the diffuser section are used in the corresponding Metal or non-metal materials are machined into shape. The material of the throat lining 1 is W-cu. The material of the backing 2 is felt carbon / carbon composite material. The material of the substrate 3 is phenolic high silica glass cloth board. The thermal insulation layer 4 of the diffusion section is made of felt carbon / carbon composite material. The thermal insulation layer and the tail ring of the diffusion section are first bonded with SW-2 glue, and then fixed circumferentially with 8 M4 hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com