Double-layered fork-shaped radial gas hydrodynamic bearing based on 3D printing technology

A gas dynamic pressure bearing and 3D printing technology, which is applied in air cushion bearings, sliding contact bearings, bearings in rotary motion, etc., can solve problems such as negation of design ideas, achieve reasonable stiffness distribution, large Coulomb damping, and improve overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions used in the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the embodiments do not limit the scope of protection claimed by the present invention.

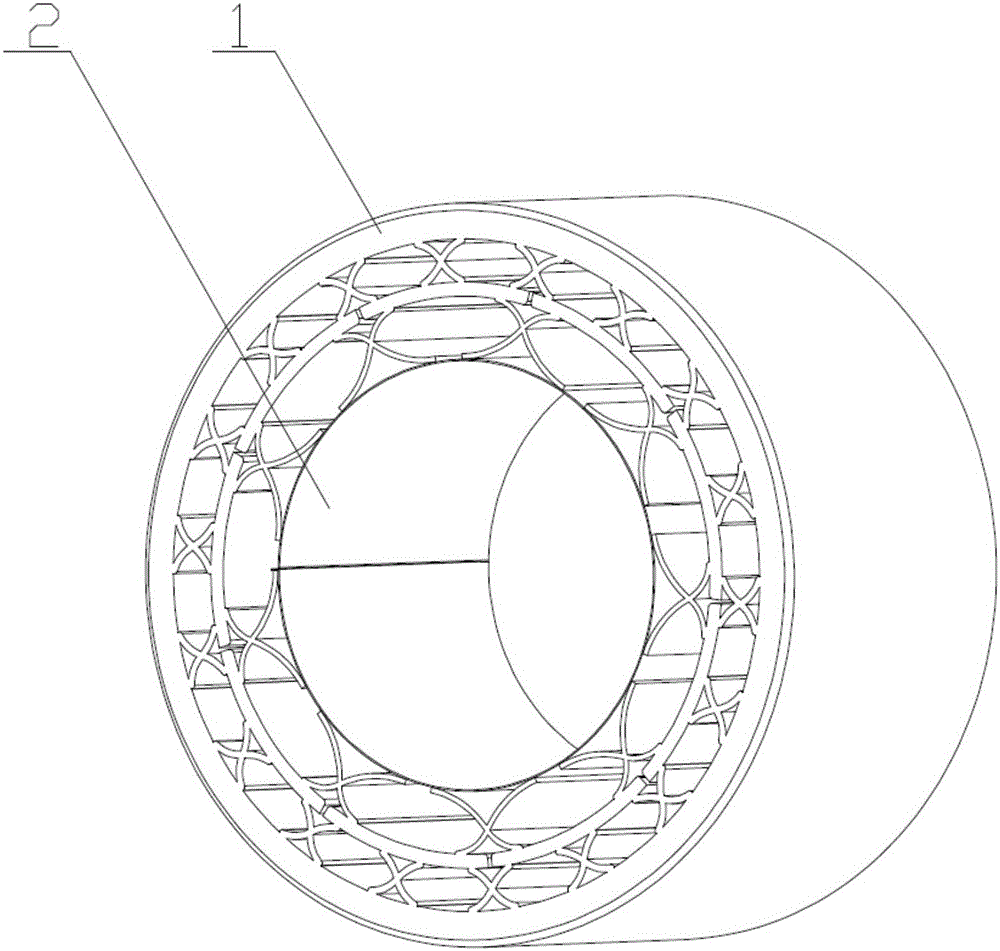

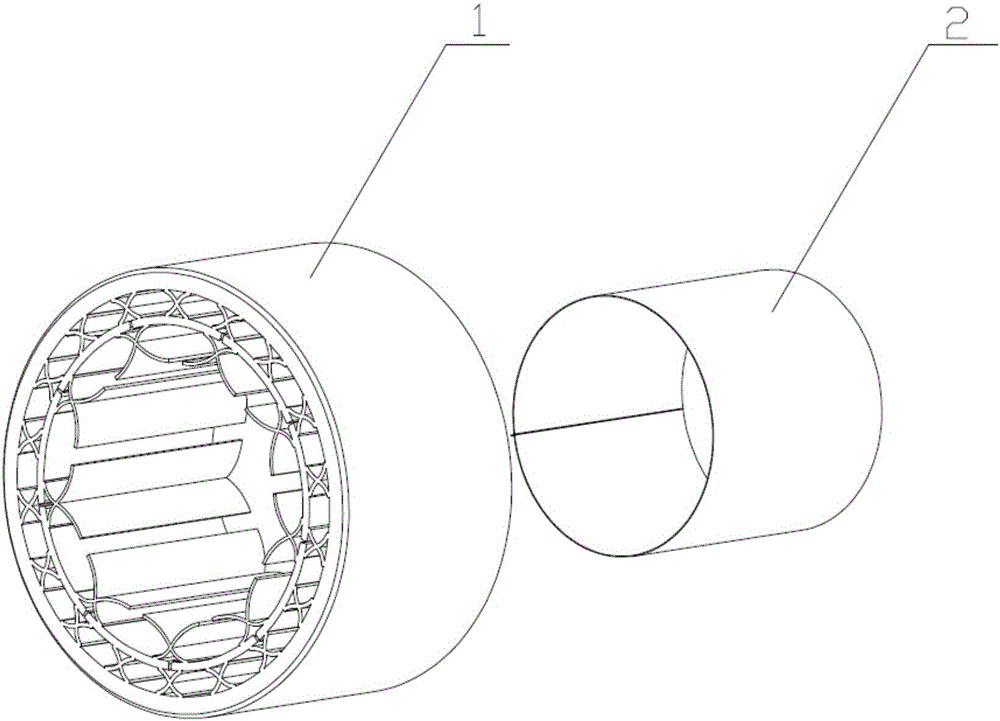

[0026] Such as figure 1 , figure 2 They are respectively the isometric view of the general assembly and the exploded view of the bearing structure of the present invention. The double-layer fork-shaped radial gas dynamic pressure bearing based on 3D printing technology is composed of two main components: an integrated variable material bearing body (1) and a top foil (2).

[0027] image 3 It is a front view of the top foil, which is a thin-walled non-closed ring structure with an overhanging structure at the opening, and is fixed with the inner fork by welding or pasting. And the inner wall of the top foil is coated with a wear-resistant coating.

[0028] Figure 4 , Figure 5 Axonometric and frontal vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com