Impedance-adjustable type refrigerating machine

A refrigerator and impedance adjustment technology, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problems that the drive and refrigerator are difficult to work at the same time, and the efficiency of refrigerators is discounted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

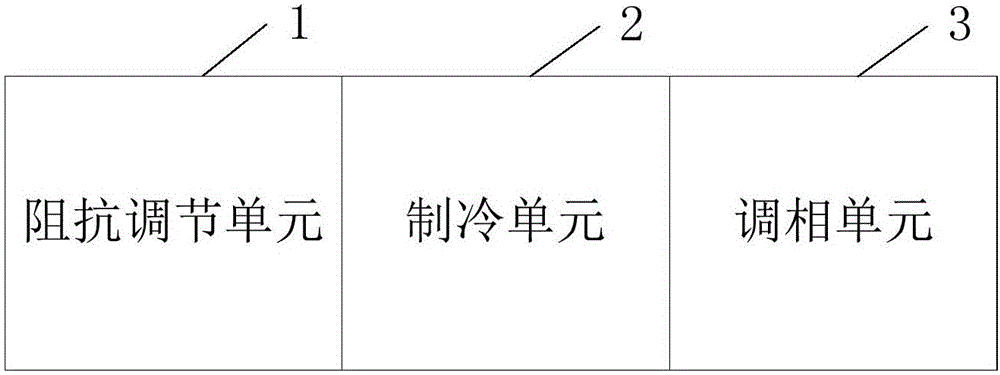

[0042] figure 1 It is a schematic structural diagram of an impedance adjustable refrigerator according to an embodiment of the present invention, which includes an impedance adjustment unit 1, a refrigeration unit 2, and a phase modulation unit 3 connected in sequence;

[0043] The impedance adjustment unit 1 is used to adjust the acoustic impedance at the connection between the driver and the impedance adjustment unit 2 to match the acoustic power of the pressure wave input by the driver;

[0044] The phase modulation unit 3 is used to adjust the impedance of the working gas in the refrigeration unit 2;

[0045] The refrigeration unit 2 is used for refrigerating the phase-modulated working gas.

[0046] The refrigerator provided in this embodiment can adjust the impedance phase angle of the refrigerator to any desired value by setting the impedance adjustment unit, so that the refrigerator and the driver can be optimally matched, and the two can work at the same time at the most ideal...

Embodiment 2

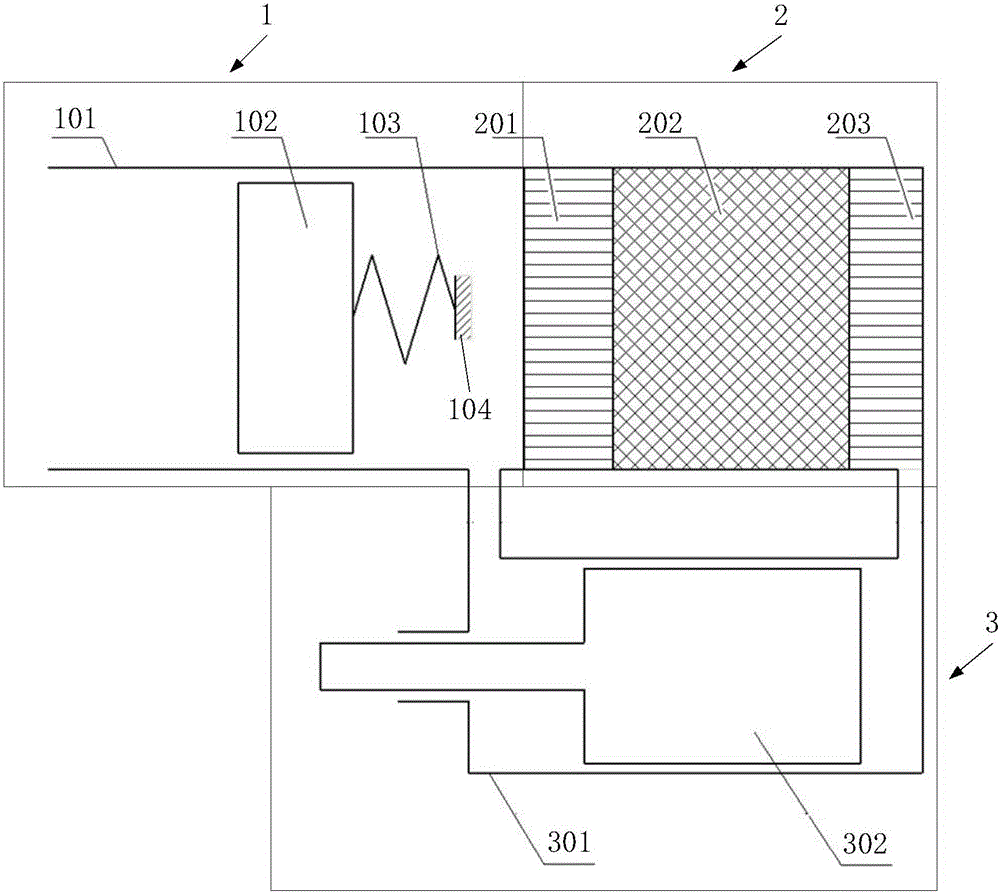

[0049] figure 2 It is a schematic structural diagram of a Stirling refrigerator with adjustable impedance according to an embodiment of the present invention, and the refrigerator is a Stirling refrigerator.

[0050] Reference figure 2 , The Stirling refrigerator is a regenerative refrigerator, and its refrigeration unit 2 includes a main radiator 201, a regenerator 202, and a low-temperature heat exchanger 203 that are sequentially connected;

[0051] The main radiator 201 is connected to the impedance adjusting unit 1, and the low temperature heat exchanger 203 is connected to the phase adjusting unit 3;

[0052] The working gas in the refrigeration unit 2 expands and absorbs heat in the low-temperature heat exchanger 203, and after passing through the heat regenerator 202, it is compressed in the main radiator 201, so as to reduce the heat in the working gas. shed.

[0053] Further, the impedance adjusting unit 1 includes a cylinder 101, a mass piston 102, and an elastic componen...

Embodiment 3

[0072] Figure 4 It is a schematic structural diagram of a pulse tube refrigerator with adjustable impedance provided by an embodiment of the present invention. The pulse tube refrigerator is a regenerative refrigerator, and the driver and refrigeration unit 2 of the refrigerator provided in this embodiment can be compared with the embodiment The second refrigeration unit 2 has the same structure.

[0073] Reference Figure 4 , The impedance adjustment unit 1 includes a cylinder 101 and a mass piston 102;

[0074] The cylinder 101 is in communication with the refrigeration unit 2, the mass piston 102 is sleeved inside the cylinder 101, and there is a gap between the inner wall of the cylinder 101 and the mass piston 102, which simultaneously serves Isolate the effect of the gas on both sides of the mass piston 102;

[0075] The inner wall of the cylinder 101 and the mass piston 102 are both stepped structures, and the inner wall of the cylinder 101 and the stepped structure of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com