Dynamic solid vacuum drying machine

A vacuum dryer, solid technology, applied in the direction of non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of reduced applicability of dryers, material pumping, difficult temperature control, etc., and improve drying efficiency , avoid waste of extraction, consistent drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

[0022] The present invention is based on the problems existing in the two kinds of drying equipment described in the background technology, a new type of dynamic solid vacuum dryer through innovation and design, which overcomes the shortcomings of the above two kinds of vacuum drying equipment, and thus is far superior in all aspects. The same kind of drying equipment at home and abroad is available.

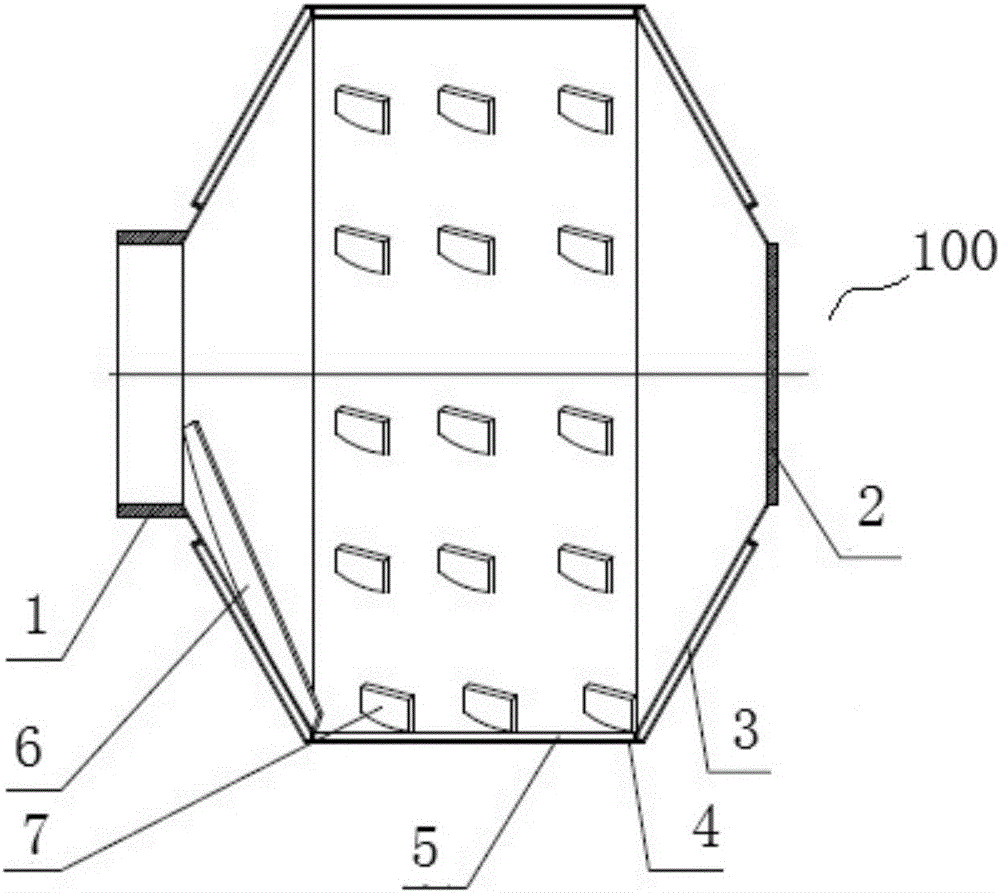

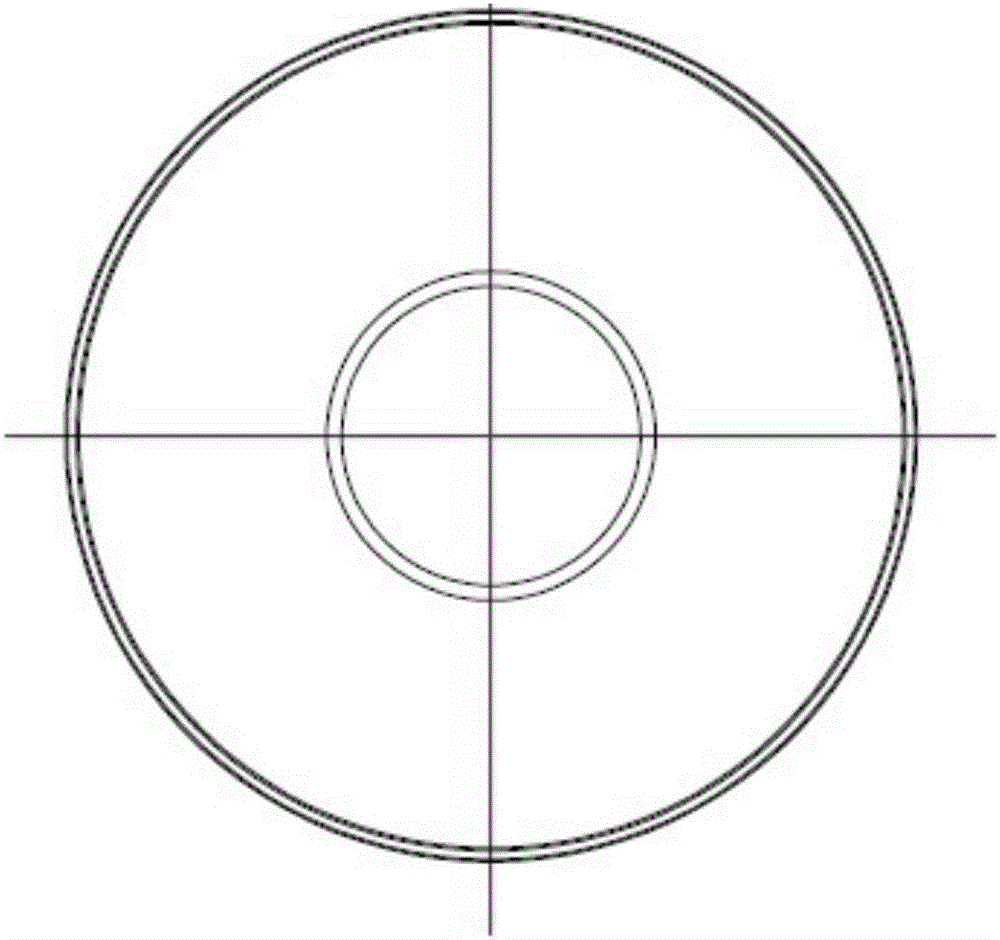

[0023] see Figure 1-2 As shown, a kind of dynamic solid vacuum drier provided by the present invention comprises a box body (not shown) that can be vacuumized, and the rotatable cylinder body 100 that material is dried is horizontally arranged in the described box body, and described cylinder The body is connected with a rotation control drive system, which can be driven by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com