Plate type heat exchanger formed by fully welding square plates via laser

A technology of plate heat exchangers and heat exchangers, applied in heat exchanger sealing devices, heat exchange equipment, indirect heat exchangers, etc., can solve the problems of metallographic changes, high manufacturing precision requirements, and low production efficiency , to achieve the effects of easy welding, reduced equipment maintenance costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

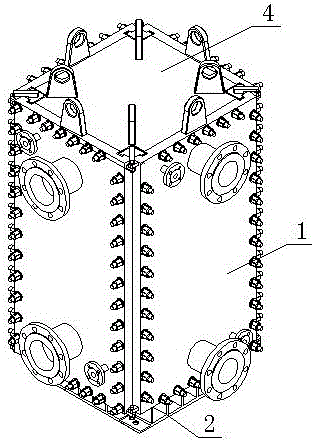

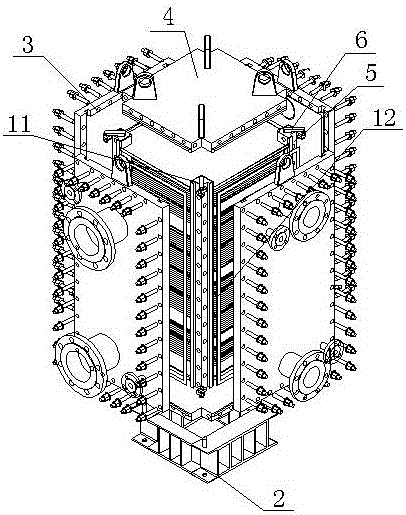

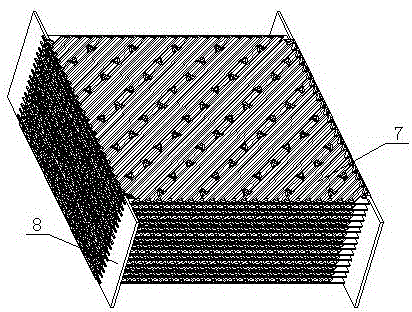

[0019] like figure 1 , 2 As shown in , 3 and 4, a square plate laser fully welded plate heat exchanger includes a heat exchanger main body 1 and a base 2 at the bottom thereof, side plates 3 are arranged around the heat exchanger main body 1, and the heat exchanger main body 1. The upper and lower ends are provided with fastening cover plates 4, the side plates 3 and the fastening cover plates 4 are fixedly connected by fastening screws, and the four edges of the heat exchanger main body 1 are provided with fastening pillars 5, and the fastening pillars 5 Both ends of the upper and lower ends of the heat exchanger are provided with a rotating shaft 6, and the main body of the heat exchanger 1 is composed of a heat exchange fin 7 and a wide-back sawtooth plate 8 at both ends of the heat exchange fin 7. Among them, the heat exchange fin 7 is evenly distributed with wave trough convex hulls and wave crest grooves, the heat exchange fin 7 and the wide-back sawtooth plate 8 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com