Plasma reaction cavity seepage detection method

A technology of plasma reaction and detection method, which is applied in the field of semiconductor manufacturing, can solve the problems of constant reading value of vacuum pressure gauge and failure to detect leakage, etc., and achieve accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

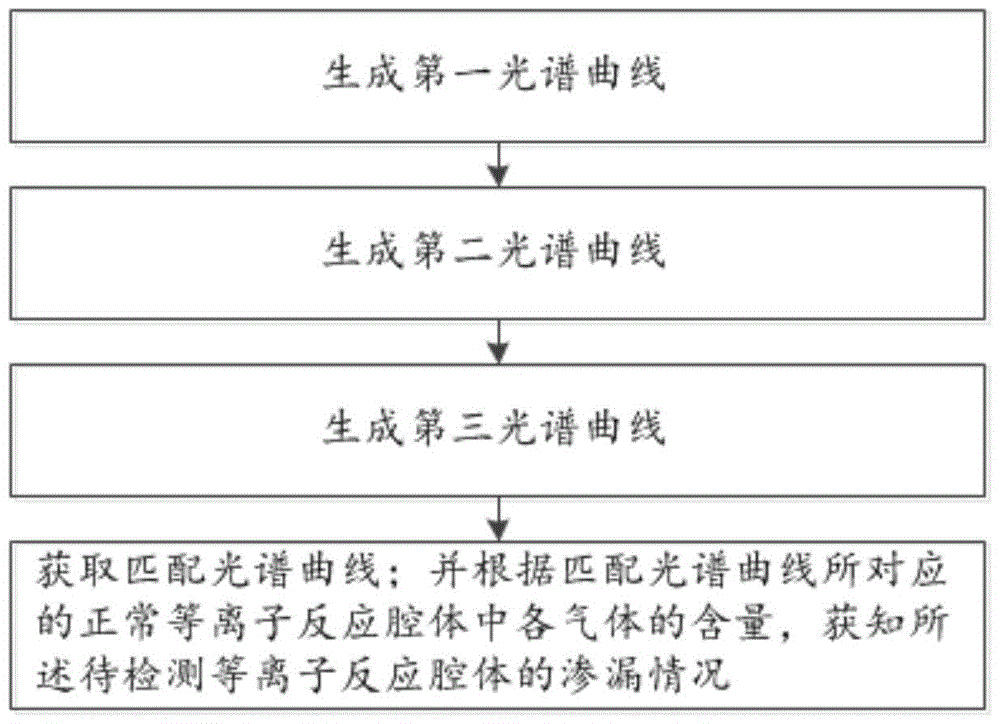

[0025] Such as figure 1 Shown, a kind of leakage detection method of plasma reaction chamber comprises the following steps:

[0026] Step 1: Introduce a predetermined content of fluoroalkyl gas and a known content of fluoroalkyl gas different from the preset content into the normal plasma reaction chamber respectively, insert preset excitation energy to ionize the gas, and respectively collecting spectral lines emitted during the ionization process to generate a first spectral curve;

[0027] Step 2: Introduce the combination gas of the fluoroalkyl gas with the preset content and other gases with different known contents into the normal plasma reaction chamber respectively, connect the preset excitation energy to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com