Spherical liquid dynamic pressure bearing floating measuring method

A technology of hydrodynamic pressure and measurement method, which is applied in the direction of mechanical bearing testing, etc. It can solve the problems of invisible floating state of dynamic pressure bearing and direct measurement of capacitance, etc., and achieve good monitoring effect and accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

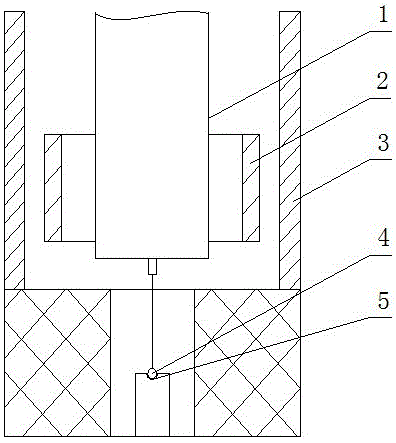

[0065] Measure the relevant dimensions of rotor 1, housing 3, bearing 4 and bearing socket 5, design and measure the size of floating ring 2, and the outer diameter of rotor 1 155mm, measure the inner diameter of the floating ring 2 is 156mm, the height L of the floating ring 2 is 75mm, and the outer diameter of the floating ring 2 is measured is 161mm, the inner diameter of shell 3 170mm, vacuum absolute permittivity for , the relative dielectric constant of the medium is PTFE 2.55, air is 1, lubricating oil is 2.4, the relative area of ball bearing 4 and bearing socket 5 is 4.87×10 -5 m 2 , the distance d between the ball bearing 4 and the bearing socket 5 is m.

[0066] but

[0067]

[0068]

[0069]

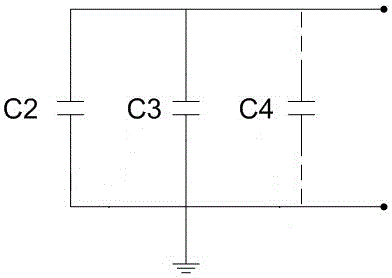

[0070] Total capacitance C when not floating

[0071]

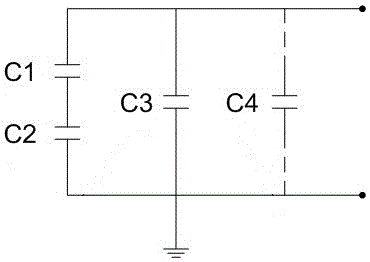

[0072] Total capacitance C' when floating

[0073]

[0074] Capacitance change

[0075]

[0076] This result is an estimate and does not take into account stray capacitance.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com