Indoor fire hydrant pressure loss automatic testing device

An automatic testing device and fire hydrant technology, which is applied in the direction of measuring devices, machine/structural parts testing, instruments, etc., can solve the problems of high labor intensity and human interference factors affecting the quality and efficiency of detection, so as to eliminate human interference and realize detection The effect of automation, improving inspection quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

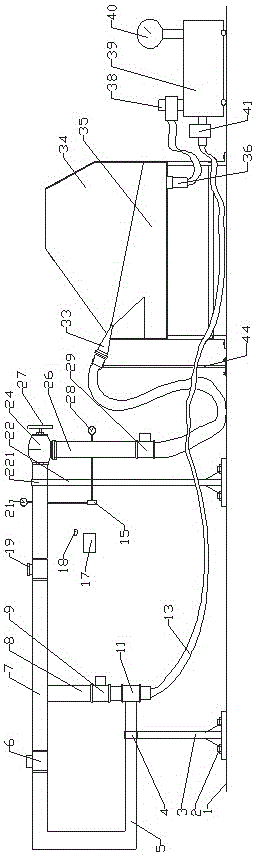

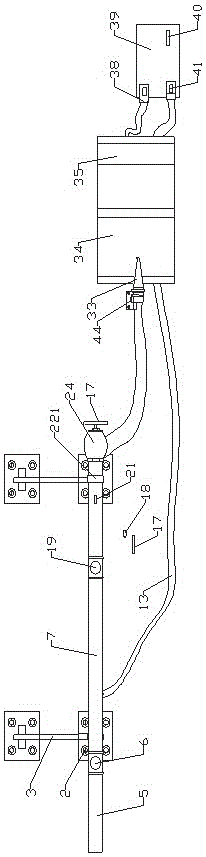

[0015] Accompanying drawing is the specific embodiment of the present invention. Such as figure 1 , figure 2 As shown, this kind of automatic test device for indoor fire hydrant pressure loss includes a PLC control system, a circulating water tank, a pressure water pump and a tee. The PLC control system is connected to a camera, and the operation of the entire system is controlled by the PLC control system. The bolt 2 is fixed with a first bracket 3, the upper end of the first bracket 3 is provided with a first fixing ring 4, the fixing ring 4 fixes the U-shaped pipe 5, one end of the connecting pipe is connected with one end of the tee, and the other end of the connecting pipe 5 A stop solenoid valve 6 is connected, the other end of the stop solenoid valve 6 is connected with a straight pipe 7, the straight pipe 7 is connected with a vertical pipe 8, a throttling solenoid valve 9 is installed on the vertical pipe 8, and the other end of the vertical pipe is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com