Device for hub detection

A detection device, hub technology, applied in measurement devices, material analysis using radiation, material analysis using wave/particle radiation, etc., can solve the problems of shortening the service life of X-ray tubes and imagers, shortage, power loss, etc., To achieve the effect of saving wheel hub loading and unloading time, improving use function and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings.

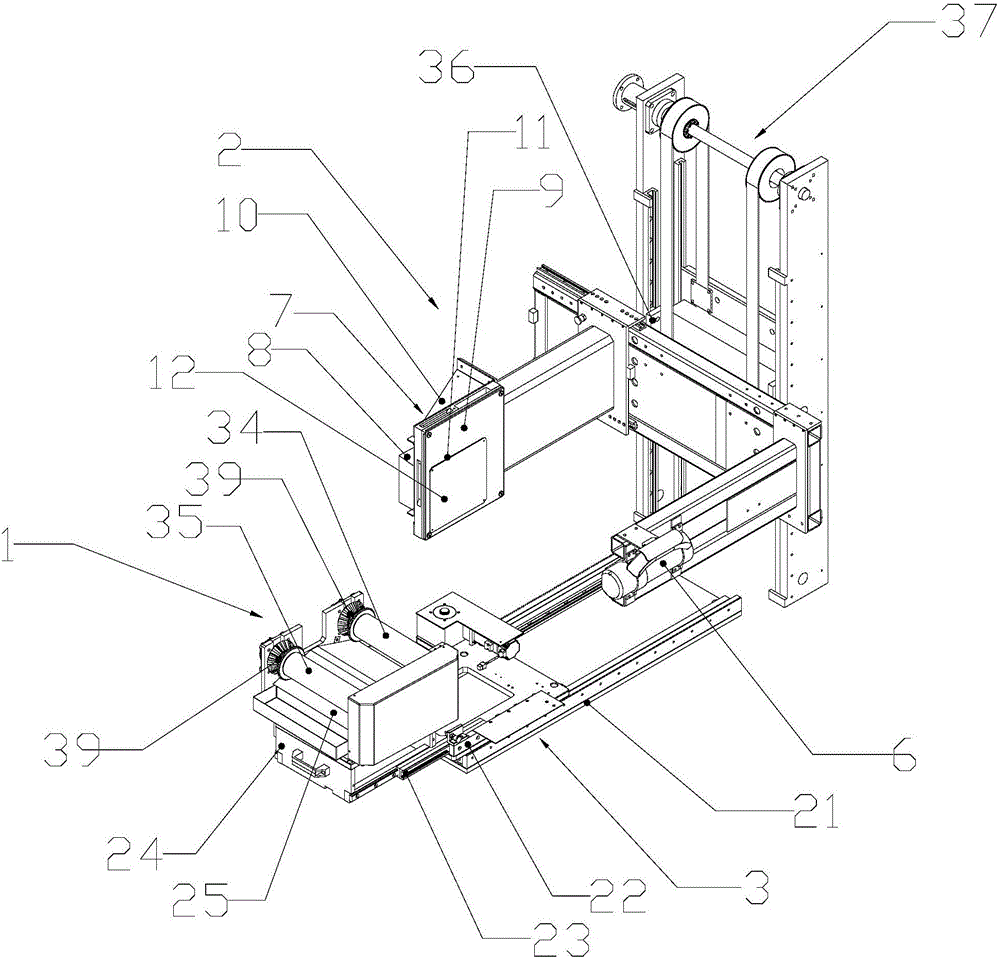

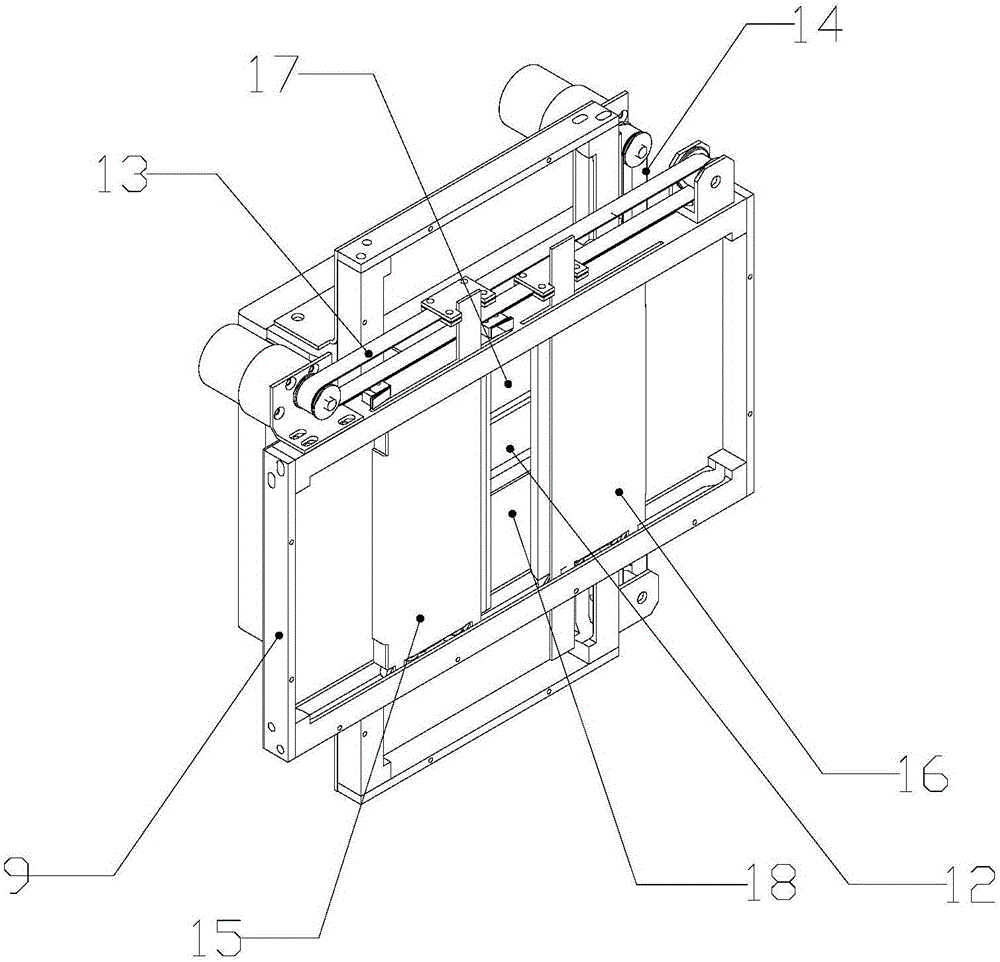

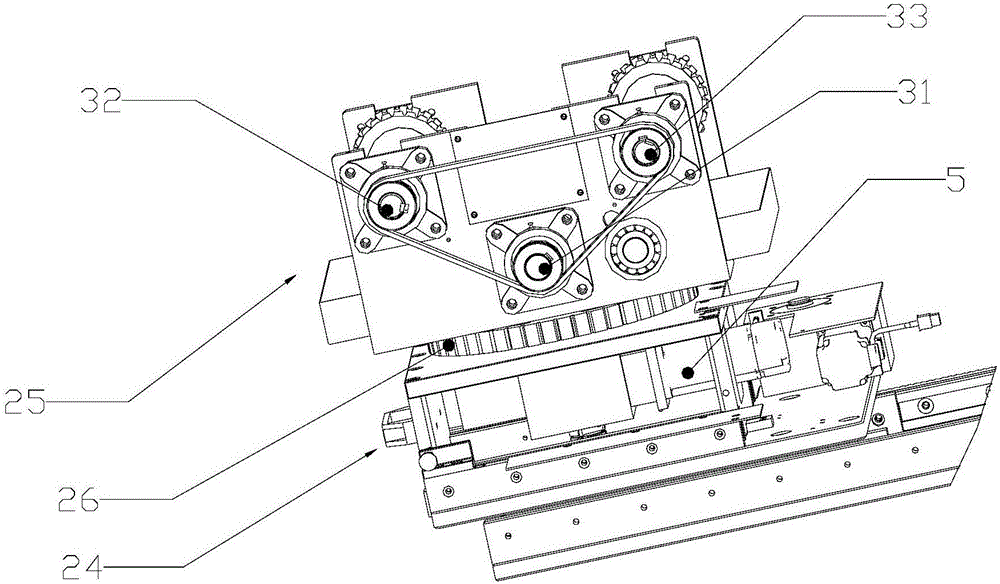

[0027] Figure 1 ~ Figure 4 A device for detecting a wheel hub according to an embodiment of the present invention is schematically shown. Such as Figure 1 ~ Figure 4 As shown, it includes a stage 1 and a detection device 2. The stage 1 is connected to the first transmission device 3 and the second transmission device respectively. The stage 1 can move horizontally under the action of the first transmission device 3, and the second transmission device The device is connected to the first driving device 5. The first driving device 5 drives the second transmission device so that the hub on the stage 1 can rotate in the horizontal and vertical directions at the same time; the detection device 2 includes an X-ray source 6, an imaging device 7, The X-ray source 6 and the imaging device 7 are located on both sides of the hub. The imaging device 7 includes a grating plate 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com