Coupling plate assembly used for electrostatic discharge test and electrostatic discharge test device

An electrostatic discharge test and coupling board technology, applied in the direction of measuring devices, measuring external source interference, measuring electricity, etc., can solve the problems of low test efficiency, complicated test process, and inaccurate test results, so as to improve test efficiency, The effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the electrostatic discharge test of the prior art, the test object is usually discharged by setting a coupling plate, because the test object has different surfaces, and when the vertical coupling discharge test is performed on the test object (EUT), it is necessary to continuously Move the EUT to test the surface to be tested. Especially when the shape of the EUT is irregular, it is difficult to conduct a full range of vertical coupling discharge tests on the EUT.

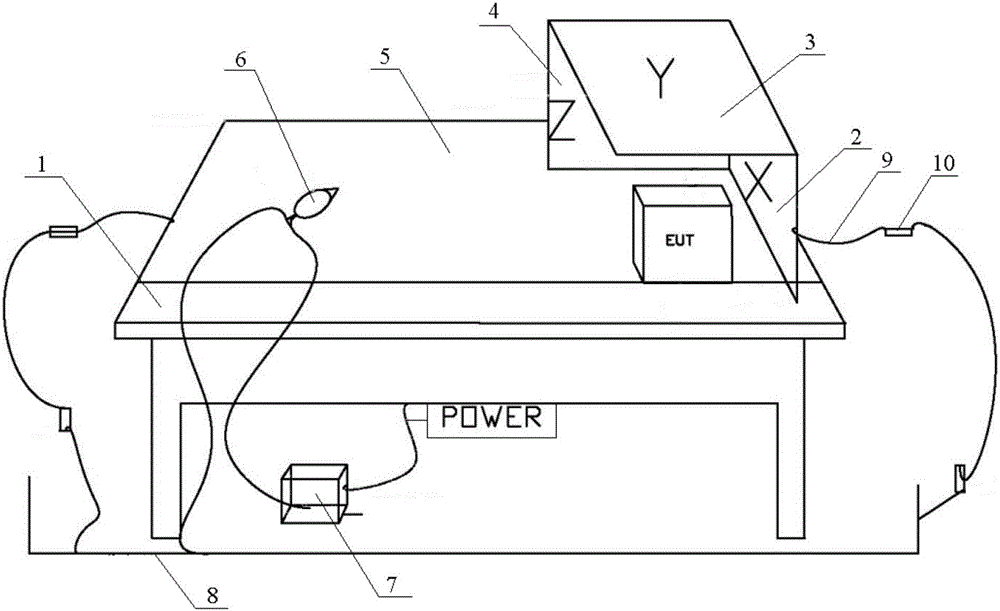

[0026] In view of the above problems, the present invention provides a coupling plate assembly for electrostatic discharge testing, such as figure 1 As shown, it includes: a horizontal coupling plate 5 laid on the test table 1, a first coupling plate 2 perpendicular to the test table 1, and a second coupling plate 3 vertically connected to the first coupling plate 1, the horizontal An insulating plate for placing the object to be measured is also arranged on the coupling plate 5 .

[0027] The second c...

Embodiment 2

[0036] Different from Embodiment 1, it also includes a fourth coupling plate parallel to the first coupling plate 2 and a fifth coupling plate perpendicular to the first coupling plate 2, the first coupling plate 2, the second coupling plate 3 , the third coupling plate 4 , the fourth coupling plate, the fifth coupling plate and the horizontal coupling plate 5 form a closed space for testing the antistatic ability of the object to be tested.

[0037] To sum up, through the coupling plate assembly composed of multiple coupling plates, a full range of vertical coupling discharge tests are performed on the object to be tested. The structure is simple and the operation is convenient, which not only improves the test efficiency, but also improves the accuracy of the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com