Funnel fire extinguishing system and fire extinguishing method

A technology for fire extinguishing systems and tunnels, applied in fire rescue and other directions, can solve problems such as low fire extinguishing efficiency, poor fire extinguishing effect, and small particle size of water mist particles, to ensure high fire extinguishing efficiency, various fire extinguishing modes, and foam state. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

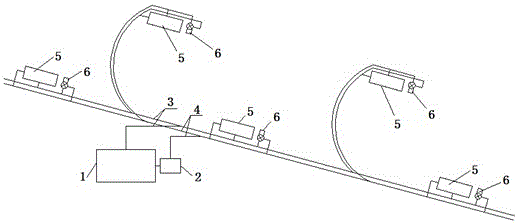

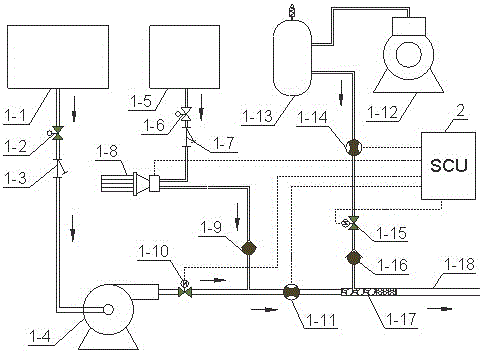

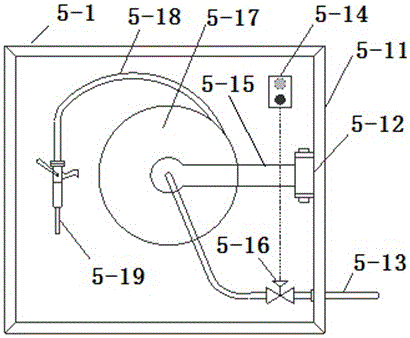

[0033] Such as figure 1 As shown, a tunnel fire extinguishing system includes a compressed air foam generating device 1 , a system controller 2 , a compressed air foam cannon 6 , and a compressed air foam plug box 5 .

[0034] Set the compressed air foam generating device 1 and the system controller 2 in the equipment cavern in the tunnel, and install several compressed air foam plug boxes 5 alternately and fixedly on the two side walls of the tunnel according to the same distance, that is, the tunnel on one side Several compressed air foam plug boxes 5 are arranged at the same distance on the wall, and one compressed air foam plug box 5 is arranged on the tunnel wall on the other side corresponding to the middle position between every two compressed air foam plug boxes 5, and the same side The distance between two adjacent compressed air foam plug boxes 5 is 30m t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com