A sponge-like air purification filter and preparation method thereof

An air purification and sponge-like technology, which is applied in the field of sponge-like air purification filter and its preparation, can solve the problems of not being able to contact with the outside air, not being able to purify the air, and clogging of pores, so as to prevent the phenomenon of binder clogging the pores, Good air purification effect and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

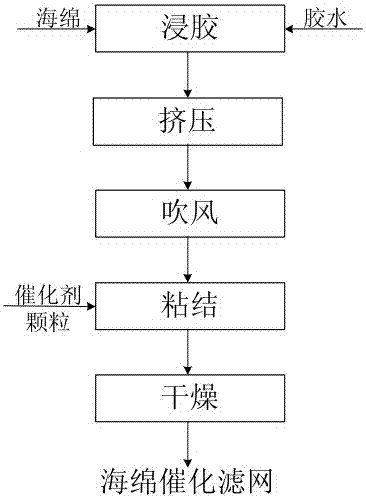

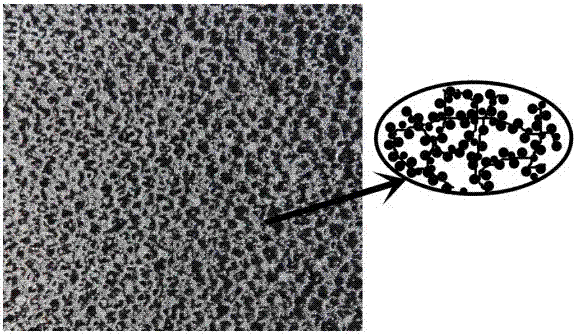

[0037] see Figure 1 to Figure 2 , choose activated carbon powder as the purification material, and use the granulation process to prepare it into spherical particles with a particle size of 40 mesh as air purification particles for use. Select a block with a pore density of 15 kg / m 3 The polyurethane sponge material is used as the skeleton carrier to prepare the target pore density of 20kg / m 3 The air purification filter screen needs to increase its pore density by adding glue. According to the previous exploratory experiments, it is known that the internal pores of the framework material can accommodate air purification material particles accounting for 60% of its pore volume, that is, each square of the framework material needs to add 5Kg of glue to achieve the target void density, and the required volume is 0.6 m 3 particles of air-purifying materials.

[0038] Submerge the above-mentioned skeleton carrier in EVA water-based glue and start timing, take it out after it i...

Embodiment 2

[0042] see Figure 1 to Figure 2 , choose activated carbon powder as the purification material, and use the granulation process to prepare it into spherical particles with a particle size of 50 mesh as air purification particles for use. Select a block with a pore density of 20 kg / m 3 The polyurethane sponge material is used as the skeleton carrier to prepare the target pore density of 24kg / m 3 The air purification filter screen needs to increase its pore density by adding glue. According to the previous exploratory experiments, it is known that the internal pores of the skeleton material can accommodate air purification material particles accounting for 60% of its pore volume, that is, each square of the skeleton material needs to add 4Kg of glue to achieve the target pore density, and the required volume is 0.6 m 3 particles of air-purifying materials.

[0043] Submerge the above-mentioned skeleton carrier in EVA water-based glue and start timing, take it out after it is ...

Embodiment 3

[0047] see Figure 1 to Figure 2 , select activated carbon powder as the purification material, and use the granulation process to prepare it into spherical particles with a particle size of 100 mesh as air purification particles for use. Select a block with a pore density of 23 kg / m 3 The polyurethane sponge material is used as the skeleton carrier to prepare the target pore density of 25kg / m 3 The air purification filter screen needs to increase its pore density by adding glue. According to the previous exploratory experiments, it is known that the internal pores of the framework material can accommodate air purification material particles accounting for 60% of its pore volume, that is, each square of the framework material needs to add 2Kg of glue to achieve the target pore density, and the required volume is 0.6 m 3 particles of air-purifying materials.

[0048] Submerge the above-mentioned skeleton carrier in the water-based PU glue and start timing. After it is comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com