Coal washing discharge device

A technology for washing and cleaning coal, applied in solid separation, centrifuges, etc., can solve the problems of environmental pollution, long cycle of water recycling, and lower production efficiency, so as to reduce production costs, reduce manual operations, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

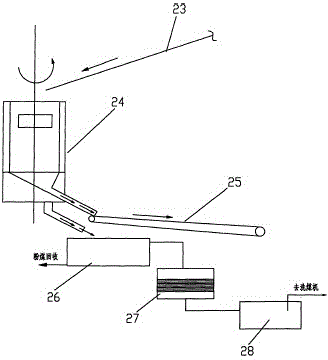

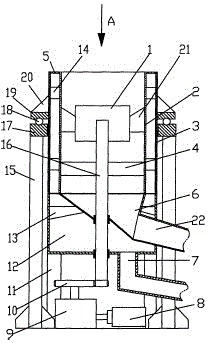

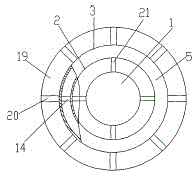

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the centrifugal dehydrator of the present invention, image 3 for figure 2 View along direction A, as shown in the figure: the coal washing and discharging device of this embodiment includes a clean coal conveying device 23 and a centrifugal dehydrator 24, and the material outlet of the clean coal conveying device 23 is connected to the material inlet of the centrifugal dehydrator 24 The centrifugal dehydrator 24 includes a centrifugal dehydration assembly and a driving device; the centrifugal dehydration assembly includes a housing 3, a liquid rejection cylinder 2 and a material receiving tray 1, and the material receiving tray 1 is driven along the axis to cooperate with a dehydration power input shaft 16. The liquid throwing cylinder 2 is coaxially fixed on the outer circle of the material receiving tray 1, and a material passing channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com