Square box bending and forming mechanism

A technology for bending and forming a square box, applied in the field of box forming, can solve the problems of reducing the vibration resistance and impact resistance of the square box, uneven thickness of the box, uneven force, etc., and achieves reduced process, simple structure, The effect of easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

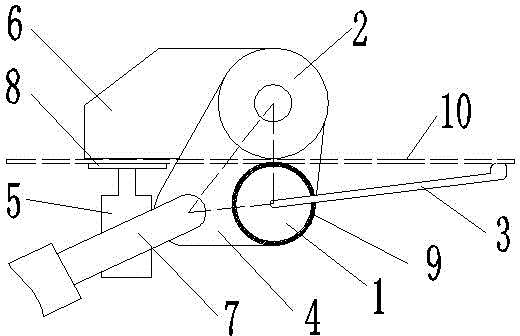

[0008] The present invention will be further explained in conjunction with the accompanying drawings.

[0009] like figure 1 As shown, the present invention includes a drum 1, a fixed roller 2, a support frame 3, an oscillating wheel 4 and a pressing cylinder 5, the oscillating wheel 4 is installed on the frame 6 through a mounting shaft and a bearing, the fixed roller 2 and the oscillating wheel 4 are in the same On the installation shaft, the roller 1 is installed on the lower end of the swing wheel 4, the piston rod 7 of the hydraulic cylinder is hinged on the swing wheel 4, the connecting line of the center of the piston rod 7, the roller 1 and the fixed roller 2 is a triangle, and the support frame 3 is fixed on the roller 1, the compression cylinder 5 is located at the lower end of the frame 6, the piston rod of the compression cylinder 5 has a compression plate 8, and the gap formed between the compression plate 8 and the frame 6 and the roller and the fixed roller 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com