Automatic oven lamp holder assembling system

An automatic assembly and lamp holder technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting product quality, wasting manpower, and low work efficiency, reducing labor costs and manufacturing costs, and improving assembly and productivity. The effect of manufacturing efficiency and reducing the number of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

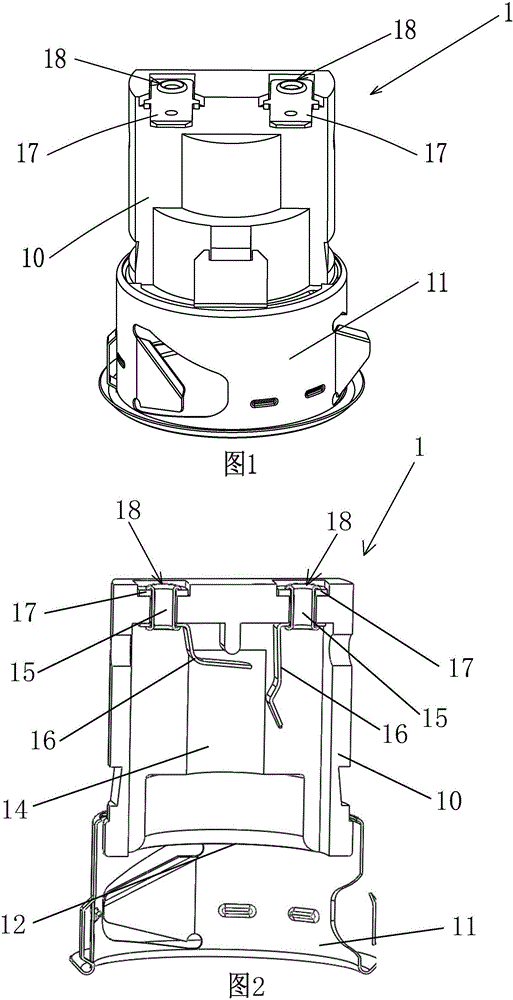

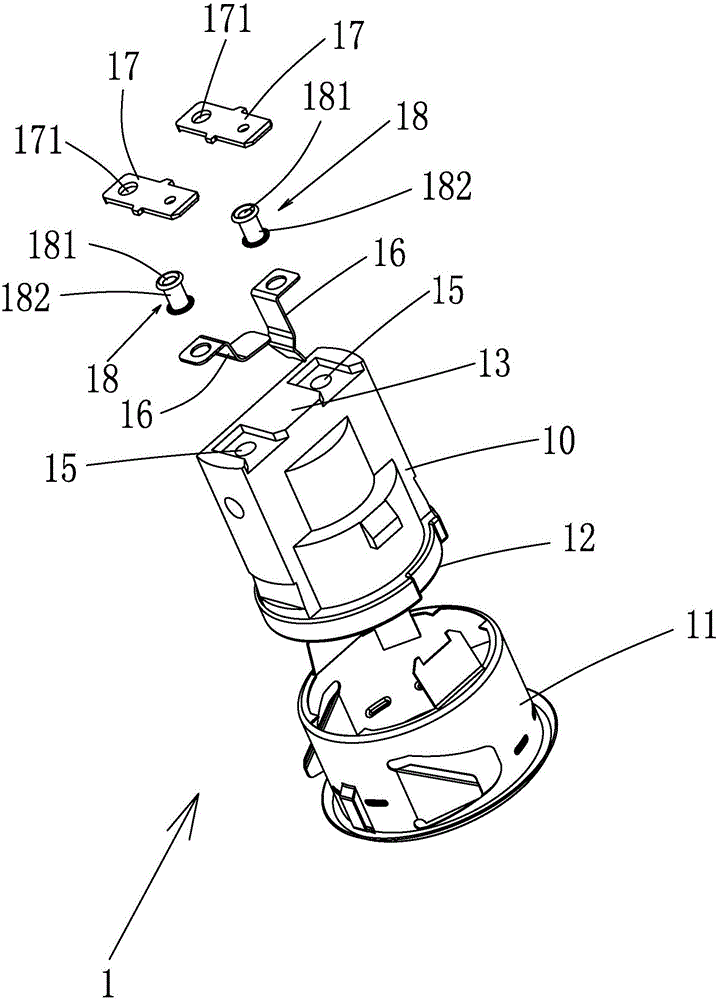

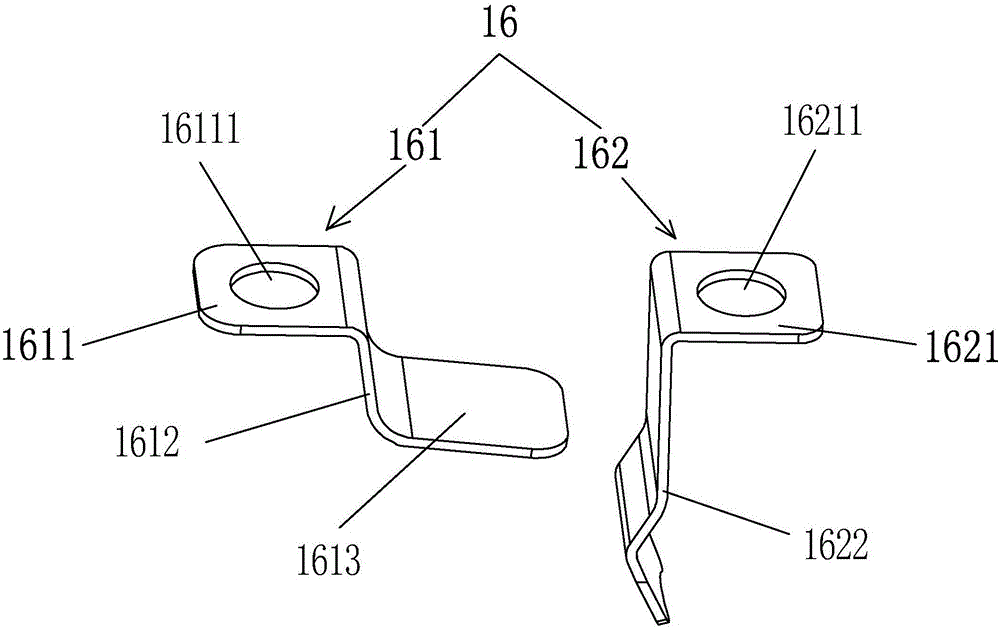

[0065] figure 1 It is the overall structure diagram of the oven lamp holder in the prior art, figure 2 yes figure 1 sectional view of image 3 yes figure 1 For an exploded view, see Figure 1~3 As shown, the lamp holder 1 in the oven includes a lamp holder main body 10, a collar 11, two conductive sheets 16, two connection terminals 17 and two rivets 18, one end of the lamp holder main body 10 is an open end 12, The other end of the lamp holder body 10 is a closed end 13, the collar 11 is sleeved and engaged on the lamp holder body 10 near the opening end 12, and the opening end 12 of the lamp holder body 10 faces the lamp holder body A bulb installation hole 14 is formed extending inside the lamp holder 10, and the bulb installation hole 14 is used for installing and fixing a bulb. One end communicates with the bulb mounting holes 14 respectively, that is, the first ends of the two first through holes 15 all lead to the inner side of the closed end 13 of the lamp holder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com