Expanding type thin-walled workpiece clamping device used for lathe machining

A thin-walled workpiece, lathe processing technology, applied in the direction of metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problem of difficulty in ensuring and controlling the size of thin-walled round tubes, affecting dimensional accuracy and shape tolerance, thermal deformation of thin-walled round tubes, etc. problem, to achieve the effect of low production cost, guarantee of workpiece processing accuracy, and convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

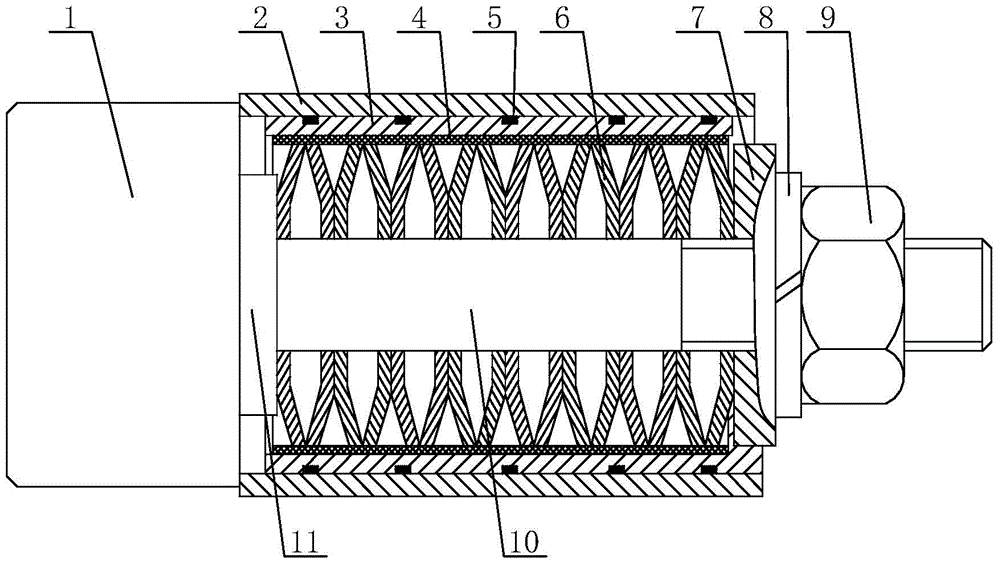

[0021] Such as figure 1 The illustrated clamping device for thin-walled workpieces with outward expansion for lathe processing includes a clamping head 1 that acts as a fixed support, and also includes a plurality of expansion sleeves 6 that expand outward under the action of an axial driving force. Install the threaded rod 10 of the expansion sleeve 6, cooperate with the expansion sleeve 6 to tighten the elastic expansion sleeve 3 of the thin-walled workpiece 2 to be processed from the inside, and to axially compress a plurality of the expansion sleeves 6 compression nut 9; one side of the clamping head 1 is fixedly connected with the front end of the threaded rod 10, and the threaded rod 10 is provided with a plurality of expansion sleeves 6, and the threaded rod 10 The tail end is sequentially provided with a pressure plate 7 and a compression nut 9 that cooperate with each other to apply an axial pre-tightening force to the expansion sleeve 6, and elastic rubber sleeves 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com