A new energy vehicle energy optimization method

A new energy vehicle, energy optimization technology, applied in the direction of road transport emission reduction, data processing management, etc., can solve the problems of output power exceeding the driver's demand, energy utilization rate decline, etc., to improve energy utilization efficiency, reduce average fuel consumption, The effect of improving driving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

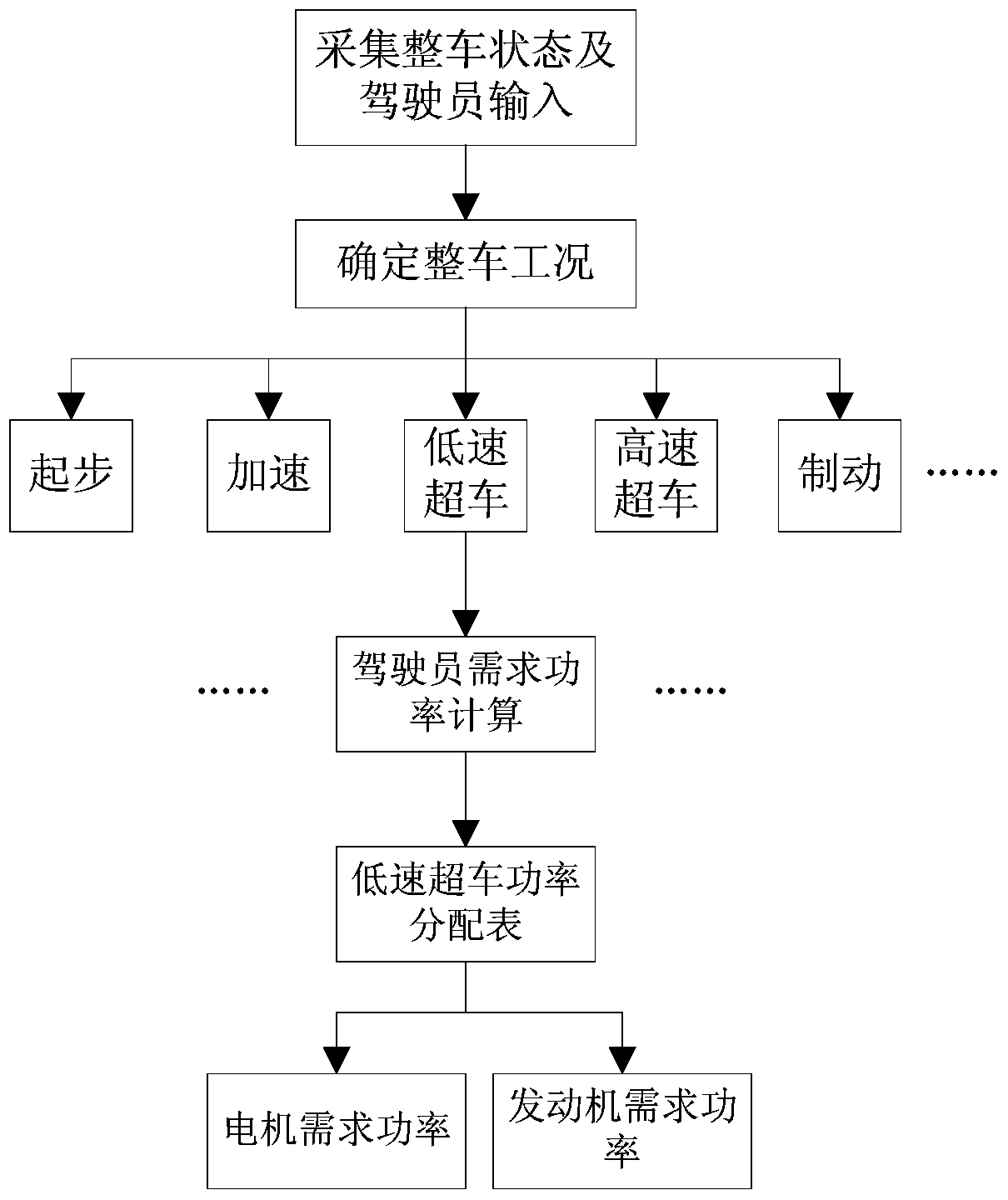

[0022] figure 1 It is a flow chart of the energy optimization method of the present invention. After collecting the vehicle state and the driver's input, first determine the current working condition of the vehicle. After the driving condition is determined, the overall power demand of the driver in the current working condition is calculated by comprehensively considering the power demand of the accessories, and then the power is allocated. After the allocation plan is determined, the required power is sent to the motor and the engine respectively.

[0023] The new energy vehicle energy optimization method described in the embodiment of the present invention comprises the following steps:

[0024] 1) During the driving of the vehicle, the vehicle controller will collect the current vehicle speed V and acceleration a in real time, and combine the driver's current input: gear position, accelerator opening, driving mode and brake switch to judge the current driver's operation I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com