Plastic-steel packing strap

A plastic-steel packing tape and plastic-steel technology, applied in the directions of packaging, transportation and packaging, flexible slender elements, etc., can solve the problems of easy scratching, sliding, affecting packaging, etc., to achieve composite consolidation and prevent oxidation of steel strips. , the effect of easy dressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

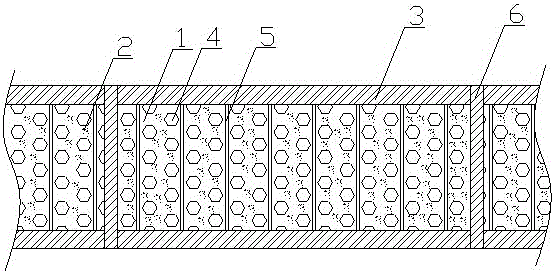

[0012] like figure 1 As shown, the plastic-steel packing belt of the present invention comprises a steel strip substrate 1, the upper surface of the steel strip substrate 1 is evenly coated with a nickel-plated layer 2, and the two side edges of the steel strip substrate 1 are coated with plastic strips 3, and the coated plastic strip The purpose of 3 is to prevent the steel belt from hurting your hands when packing items.

[0013] There are multiple groups of anti-slip convex surfaces 4 evenly formed on the surface of the steel strip substrate 1, which makes the surface of the steel strip rough and has good anti-skid performance. Anti-skid straight lines 5 are formed on the steel strip substrate 1 between two adjacent groups of anti-skid convex surfaces 4, which are non-slip The two ends of the straight grain 5 are connected to the plastic belt 3 on both sides of the steel strip substrate 1, and the plastic-steel packing belt is provided with reinforced plastic segments 6 eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com