Cross belt type sorting device

A sorting device and cross-belt technology, applied in the field of logistics, can solve the problems of only one-sided unloading, separation of loading and unloading functions, etc., and achieve the effect of simple structure and flexible sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

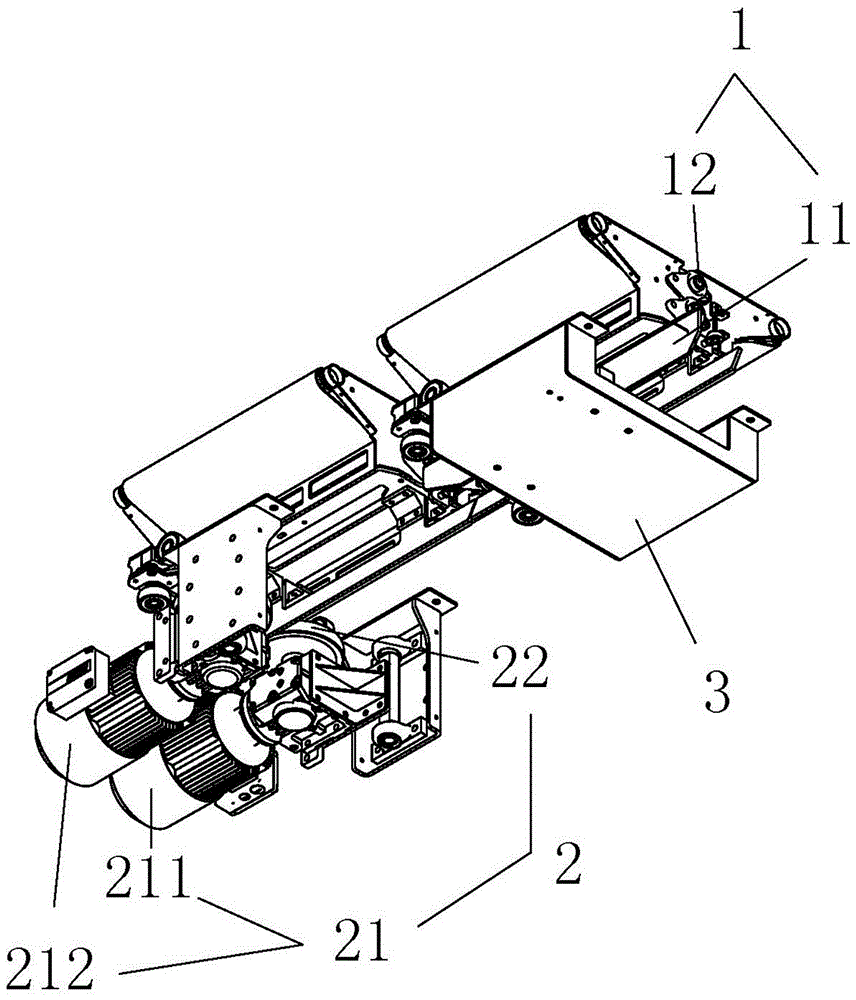

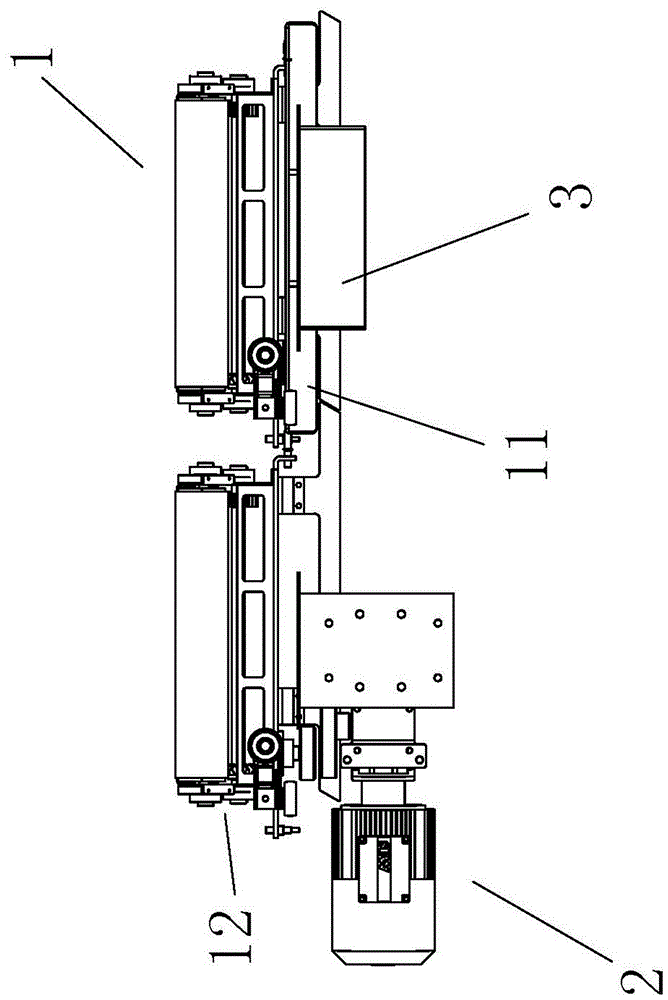

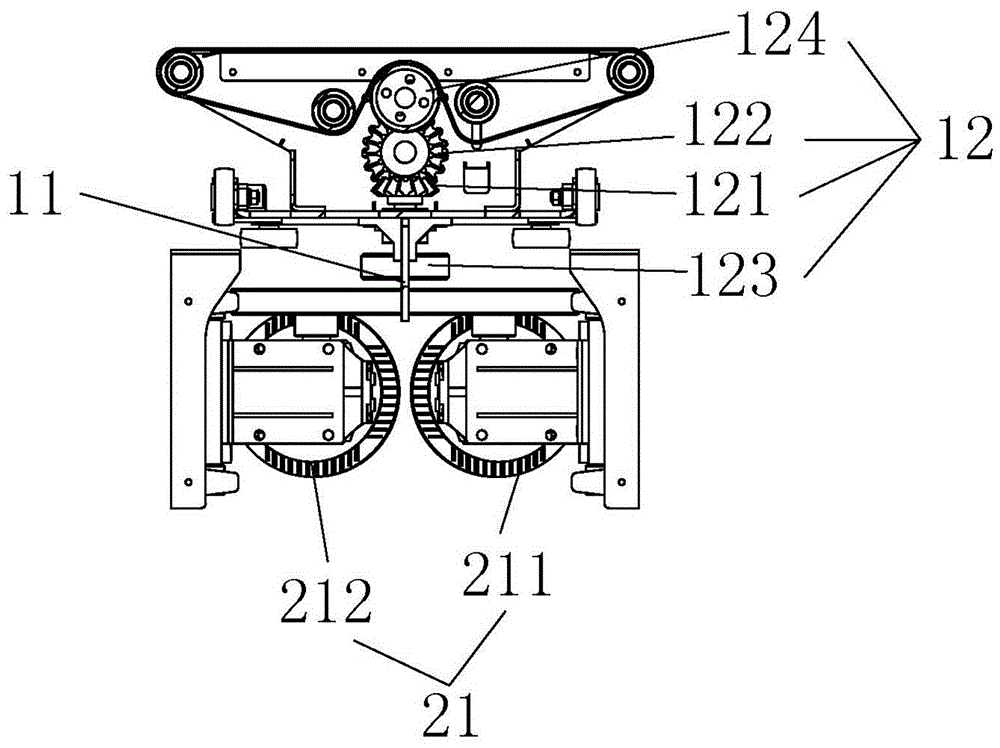

[0028] Embodiment 1: A cross-belt sorting device, characterized in that it includes a sorting structure 1, a driving structure 2 for making the sorting structure 1 travel along the main conveying line, and a driving structure 2 for making the sorting structure 1 Two-way transmission structure with forward or reverse operation 3.

[0029] The sorting structure 1 includes an exercising part 11 that is pressed against the driving structure 2 to accept the friction force of the driving structure 2 and moves with the sorting structure 1 , and cooperates with the bidirectional transmission structure 2 The transmission part 12 is used to receive the transmission force of the bidirectional transmission structure 2 and generate forward and / or reverse operation. The driving structure 2 is fixed on the main conveying line, including a driving component 21, and an intermediate component 22 that cooperates with the sorting structure 1 and provides driving friction to the sorting structure ...

Embodiment 2

[0035] Embodiment 2: The difference between Embodiment 2 and Embodiment 1 is that the two-way transmission structure 3 is a motor that is parallel to the installation axis of the transmission part 12 and overlaps the installation plane. The motor directly drives the rotating roller, which is realized by the forward rotation and reverse rotation of the motor The two directions of the conveyor belt are fed, and at the same time, the feed speed of the conveyor belt is changed by adjusting the motor speed.

Embodiment 3

[0036] Embodiment 3: The difference between embodiment 3 and embodiment 1 is that the first toggle part 322 and the second toggle part 323 have two pairs of toggle surfaces, and the two pairs of toggle surfaces protrude from the During the stroke, the two adjacent transmission wheels 123 are rotated in the same direction, and during the retraction stroke, the two adjacent transmission wheels 123 are opposite to those when they are stretched out, but the two are the same turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com