A kind of concrete penetrating sealing curing agent and its construction technology

A sealing curing agent and construction technology technology, which is applied in the field of cement floor improvement coatings, can solve the problems of performance difference, whitening of efflorescence, and the inability of material additives to completely copy imported products, so as to increase compactness and prolong service life , Improve the effect of strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

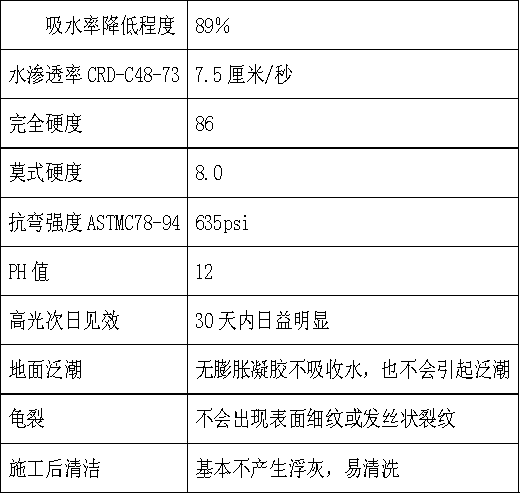

Image

Examples

example 1

[0071] Firstly, prepare the concrete penetrating seal curing agent: use magnesium fluorosilicate and zinc fluorosilicate with a modulus of 1.5. Weigh 20 g of magnesium fluorosilicate, 12 g of zinc fluorosilicate, 4 g of hydrofluoric acid, and 4 g of hydroxyethyl cellulose according to the formula. Mix the weighed components evenly, add 60g of water at room temperature and stir at a constant speed for 60 minutes. The prepared concrete penetration sealing curing agent solution is uniform, stable and transparent, ready for use.

[0072] Specific ways:

[0073] Use a professional floor scrubber to clean the dirt on the ground

[0074] After the ground is completely dry, spray the concrete penetration seal curing agent on the concrete surface to make it fully wet;

[0075] Brush the ground lightly with a brush, rubber broom or row mop, and keep it penetrating for 20-30 minutes;

[0076] After 60 minutes of infiltration, when the material gradually becomes viscous, spray water mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com