Polymer supercritical gas foaming production line

A supercritical gas and production line technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of non-recycling, increased production costs, gas waste, etc., to eliminate production costs, The effect of improving production efficiency and increasing profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

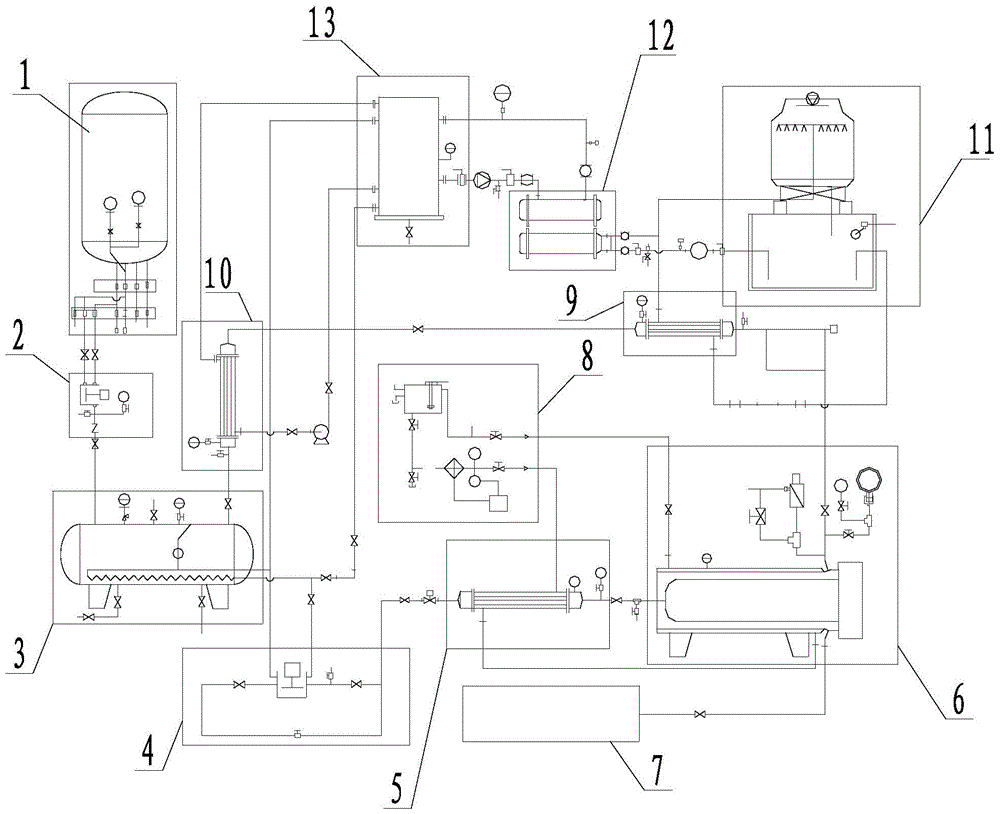

[0016] Such as figure 1 , the present embodiment provides a polymer supercritical gas foaming production line, including a production module, a thermal oil heating furnace 8 and a cooling module; , gas circulation storage tank 3, gas booster pump 4, gas heater 5, reaction kettle 6 and normal pressure drying furnace 7; described gas heater 5 and reaction kettle 6 are connected with thermal oil heating furnace 8, and heating oil passes through The hot oil outlet of the hot oil heating furnace 8 enters the gas heater 5 and the reaction kettle 6 in turn, and then flows into the hot oil heating furnace 8 through the hot oil return port; the cooling module includes a cold water circulation device 11, a refrigeration unit 12 and The cold water storage tank 13 and the refrigeration unit 12 are respectively connected with the cold water circulation device 11 and the cold water storage tank 13, and the water in the cold water circulation device 11 is further cooled and then introduced i...

Embodiment 2

[0018] This embodiment provides a polymer supercritical gas foaming production line. Compared with the production line in Embodiment 1, this embodiment has been further improved: the cooling water circulation device 10 is connected with the primary condenser 9, and the supercritical gas is initially Cooling: the cold water storage tank 13 is connected with the deep condenser 10, and the supercritical gas is cooled twice, so that the original cooling system of the production line is used to cool down the gas recovery system. equipment purchase and maintenance costs. In addition, according to different types of polymers, the reactor 6 can be configured as a horizontal reactor or a vertical reactor.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap