A self-cleaning color solar heat reflective coating

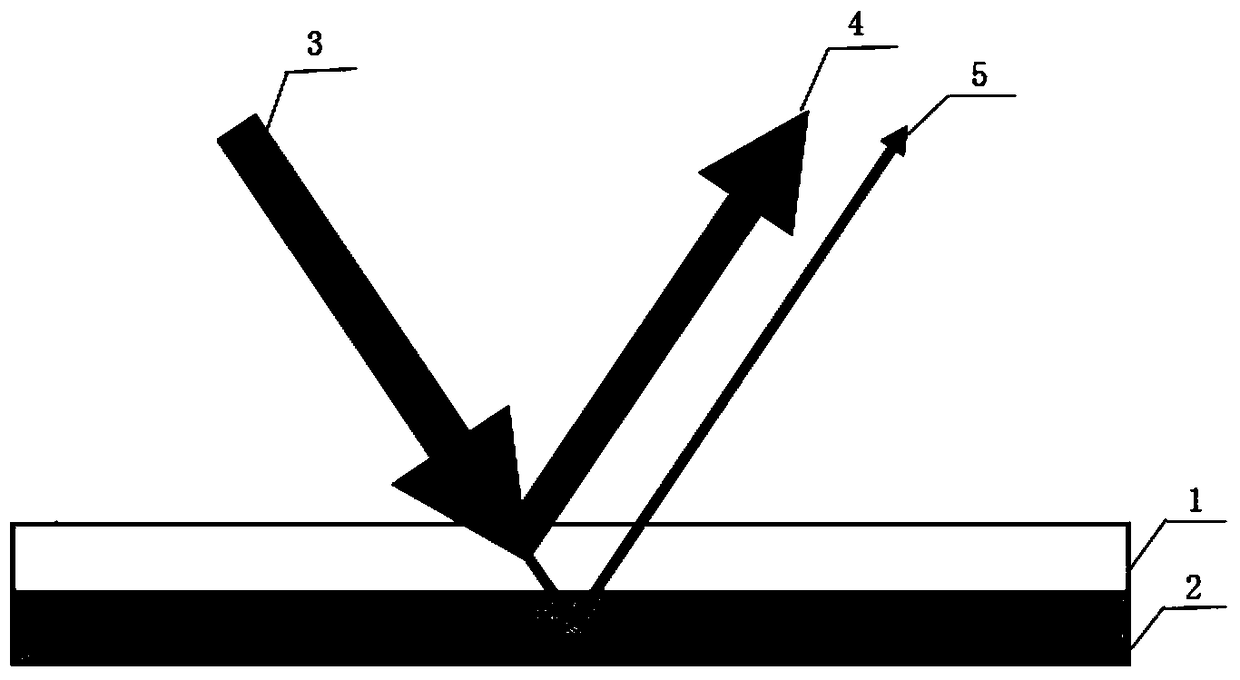

A technology of reflective coatings and solar heat, applied in the direction of reflection/signal coatings, multi-color effect coatings, anti-fouling/underwater coatings, etc., can solve problems such as single color, inability to meet individual needs, and reduced ability to reflect solar radiation , achieve high solar heat reflectivity, excellent infrared reflection energy, and enhance the effect of secondary reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] According to the present invention, the preparation method of the solar heat reflective paint finish may include: mixing and stirring each component in the finish paint composition, and then filtering, and the filtrate obtained by filtering is the solar heat reflective paint top coat.

[0039] According to a preferred embodiment of the present invention, the preparation method of the solar heat reflective paint topcoat may include: putting fluorocarbon resin and organic solvent into a dispersion tank for stirring, and sequentially stirring at a speed of 300-500 rpm. Put in dispersant, titanium dioxide, near-infrared reflective pigment, defoamer, increase the speed to 1500 rpm, disperse at high speed for 1.5-2 hours, use a scraper fineness meter to detect the fineness below 30 microns, and reduce the speed to 300 rpm, then add leveling agent, anti-settling agent and superhydrophobic agent, stir evenly, then filter, and the filtrate obtained by filtering is the solar heat...

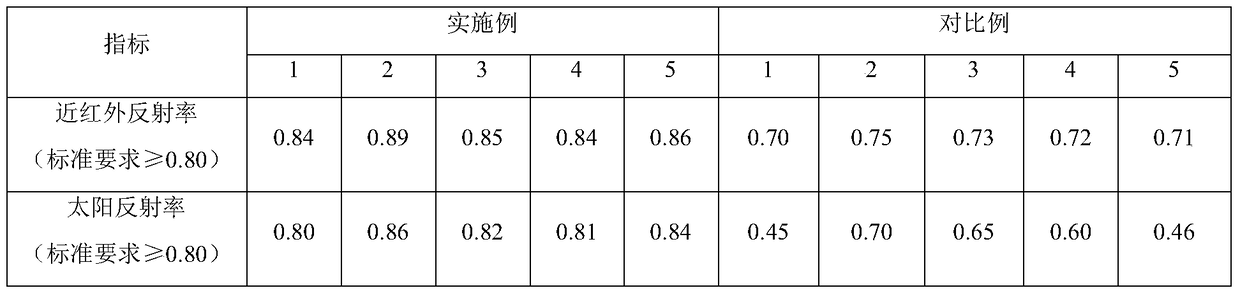

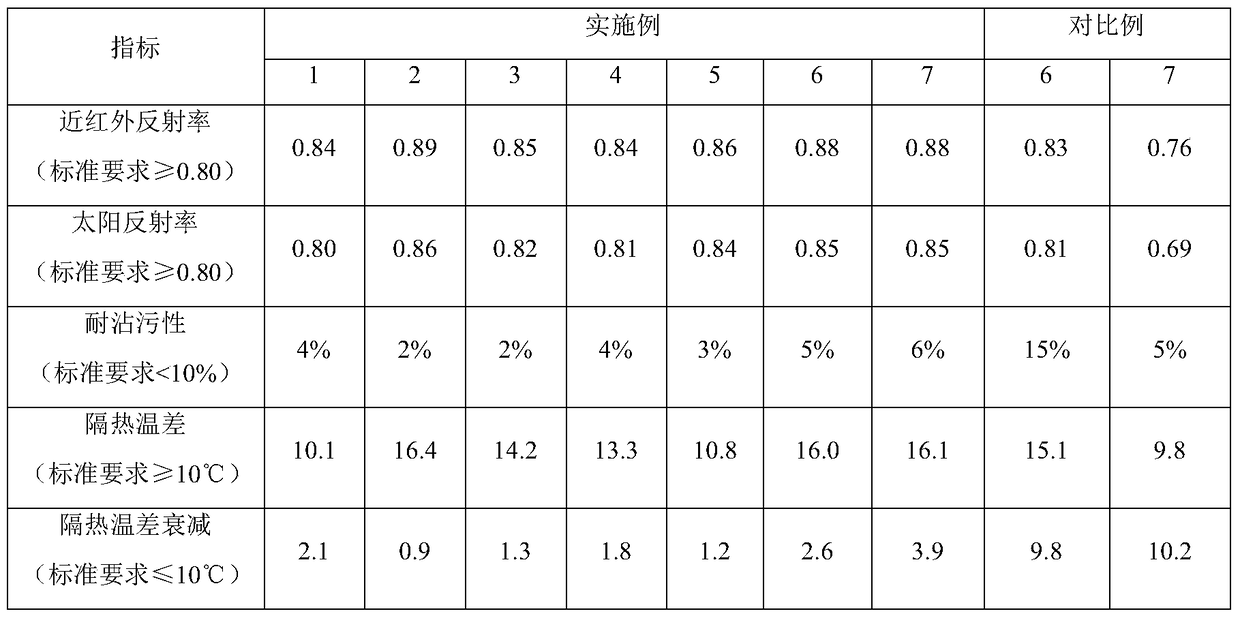

Embodiment 1

[0049] 100 parts by weight of fluorocarbon resin (purchased from Changshu Sanaifu Zhonghao Chemical New Material Co., Ltd., brand JF-2X) and 20 parts by weight of organic solvent xylene (purchased from Shanxi Xinhai Chemical Co., Ltd., brand xylene) Drop into the dispersing tank and stir, and the content of dispersing agent (purchased from German BYK Chemical Co., Ltd., brand BYK142) is successively dropped into 2 parts by weight at a speed of 500 rpm, and the average particle size is rutile titanium dioxide of 0.7 microns (purchased from Japan TAYCA company, brand TITANIX JR-1000) 40 parts by weight, 4 parts by weight of near-infrared reflective pigment iron chromium black (purchased from TOMATEC company, brand 42-7 series), defoamer (purchased from Deqian Chemical Co., Ltd. company, brand 5800) content is 0.2 parts by weight, turn up the rotating speed to 1500 rev / min, disperse at a high speed for 1.5 hours, detect the fineness to below 30 microns with a scraper fineness mete...

Embodiment 2

[0052] 100 parts by weight of fluorocarbon resin (purchased from Changshu Sanaifu Zhonghao Chemical New Material Co., Ltd., brand JF-2X), xylene (purchased from Shanxi Xinhai Chemical Co., Ltd., brand xylene): n-butyl acetate (purchased from Jiangsu Sanmu Chemical Co., Ltd., brand n-butyl acetate): the weight ratio of ethylene glycol ether acetate (purchased from Jiangsu Sanmu Chemical Co., Ltd., brand ethylene glycol ether acetate) is 1:0.8:1 30 parts by weight of the mixed organic solvent is dropped into the dispersing tank and stirred, and 3 parts by weight of dispersant (purchased from German BYK Chemical Co., Ltd., brand BYK142) are successively dropped into at a speed of 500 rpm, and the average particle diameter of 45 parts by weight is 0.9 micron rutile titanium dioxide (purchased from Japan TAYCA company, brand TITANIX JR-1000), 10 parts by weight of near-infrared reflective pigment titanium nickel yellow (purchased from TOMATEC company, brand 42-7 series), 0.6 parts b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com