Preparation method of joint sealing material

A technology of sealing material and polyether polyol, which is applied in the field of sealants, can solve problems such as limited application, and achieve the effect of high bonding strength and good caulking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The technical solution of the present invention is, a kind of preparation method of caulking sealing material, comprises the following steps:

[0032] A material preparation

[0033] 1) Component A: (parts by weight)

[0034] Polyether polyol DL-2000D60-80

[0035] Polyether polyol EP-330N10-30

[0036] Diphenylmethane diisocyanate MDI-5010-20

[0037] 2) Component B: (parts by weight)

[0038] Polyether polyol EP-330N30-60

[0039] Chlorinated Paraffin-5250-60

[0040] Amine Chain Extender (MOCA) 5

[0041] Organometallic Catalyst 1

[0043] Softeners and defoamers14

[0044] b. Preparation

[0045] Add the polyether polyol in component A into the container, stir, heat up to 60-80°C, add MDI-50, heat up to 80°C, react at 80±2°C for 2 hours, and measure the NCO content of the system when it reaches the predetermined value , stop responding. After the reaction is completed, lower the temperature and vacuum defoam for 30 minutes, and di...

Embodiment 1

[0070] Operate according to the steps A, B, D, and E described in the above specific embodiments. in:

[0071] A material preparation

[0072] 1) Component A: (parts by weight)

[0073] Polyether polyol DL-2000D60

[0074] Polyether polyol EP-330N10

[0075] Diphenylmethane diisocyanate MDI-5010

[0076] 2) Component B: (parts by weight)

[0077] Polyether polyol EP-330N30

[0078] Chlorinated paraffin-5250

[0079] b. Preparation

[0080] Add the polyether polyol in component A into the container, stir, and raise the temperature to 60°C;

[0081] After component B is stirred and dispersed evenly, it is heated to 100°C.

Embodiment 2

[0083] Repeat Example 1 only,

[0084] A material preparation

[0085] 1) Component A: (parts by weight)

[0086] Polyether polyol DL-2000D80

[0087] Polyether polyol EP-330N30

[0088] Diphenylmethane diisocyanate MDI-5020

[0089] 2) Component B: (parts by weight)

[0090] Polyether polyol EP-330N60

[0091] Chlorinated paraffin-5260

[0092] b. Preparation

[0093] Add the polyether polyol in component A into the container, stir, heat up to 80°C, add MDI-50, heat up to 80°C, after the reaction is complete, cool down and vacuum defoam for 20 minutes;

[0094] After component B is stirred and dispersed evenly, it is heated to 110°C and vacuum dehydrated for 2 hours.

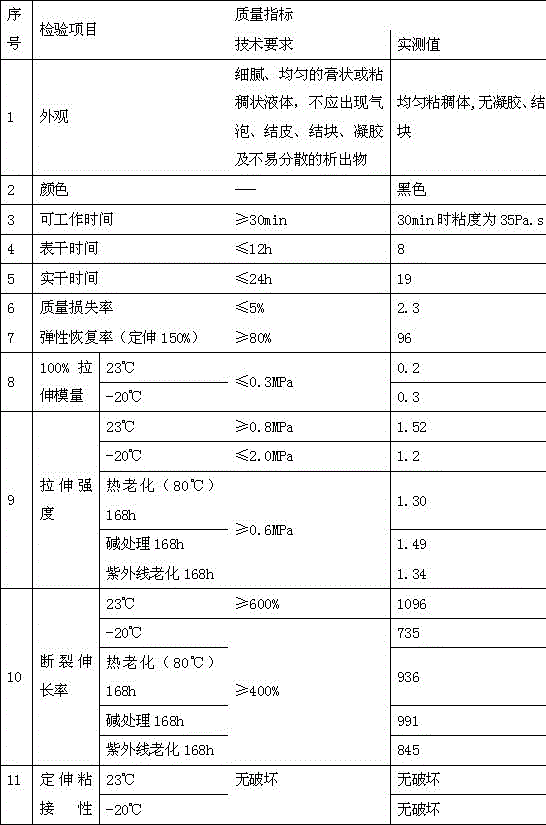

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com