Oxygen pipeline system and anti-flammation device for super-large converter oxygen lance valve station

A converter oxygen lance and oxygen pipeline technology, which is applied in the manufacture of converters, etc., can solve the problems of valve station pipeline explosion, pipeline collision, sparks, etc., and achieve the effect of solving safety problems, ensuring normal operation, and safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

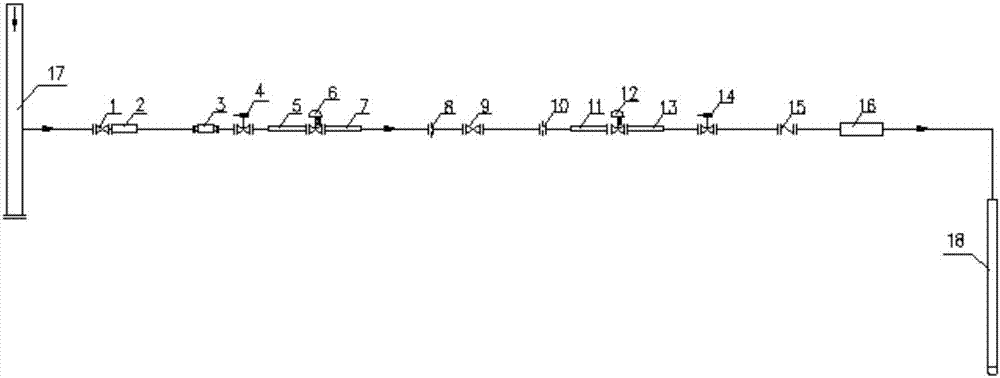

[0012] from figure 1 It can be seen from the figure that: an oxygen pipeline system and an explosion-proof device for a super-large converter oxygen lance valve station, including an oxygen main pipe 17 and an oxygen lance 18, the air inlet of the oxygen main pipe 17 is connected to the converter oxygen lance valve station Corresponding connection, characterized in that: the oxygen pipeline system and anti-explosion device of the super-large converter oxygen lance valve station also includes oxygen special shut-off valve Ⅰ1, oxygen flame arrester Ⅰ2, peeking oxygen special filter 3, and oxygen special pneumatic shut-off valve Ⅰ4 , Oxygen flame arrester Ⅱ5, Oxygen-specific pneumatic regulating valve Ⅰ6, Oxygen flame arrester Ⅲ7, Oxygen-specific flow orifice Ⅰ8, Oxygen-specific stop valve Ⅱ9, Oxygen-specific flow orifice Ⅱ10, Oxygen flame arrester Ⅳ11, Oxygen-specific pneumatic regulating valve Ⅱ12, Oxygen flame arrester V13, oxygen-specific pneumatic shut-off valve II14, oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com