A Foldable Assembled Highway Steel Bridge Erection Platform

A prefabricated, platform technology, applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve the problems of rapid physical energy consumption of operators, uneven ground settlement, and difficult physical support, so as to improve the operation speed and safety. The effect of reducing labor intensity and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The examples listed in the present invention are only used to help the understanding of the present invention. It should not be understood as limiting the scope of the present invention. For those of ordinary skill in the art, on the premise of not departing from the idea of the present invention, the present invention can also be improved and modified, and these improvements and modifications also fall into the rights of the present invention. within the scope of protection.

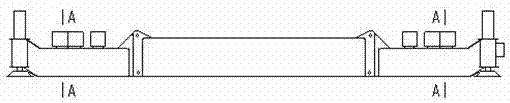

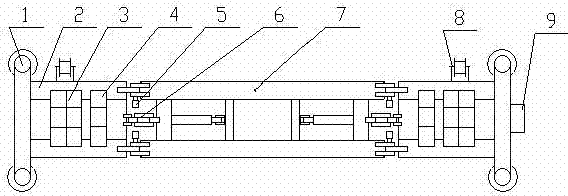

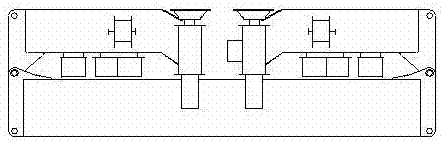

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a foldable assembled highway steel bridge erecting platform consists of an oil cylinder outrigger assembly 1, a side bracket 2, a double-row erection roll assembly 3, a single-row erection roll assembly 4, an oil cylinder latch assembly 5, and an oil cylinder The turning mechanism assembly 6, the middle bracket 7, the hydraulic winch 8 and the hydraulic control system 9 are composed, and the overall structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com