Salvaging and collecting system for rubbish in water body

A collection system and garbage technology, applied in water conservancy projects, cleaning of open water surfaces, ships, etc., can solve the problems of narrow coverage and low efficiency, and achieve the effect of reducing labor force, wide application, and large water filtration volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

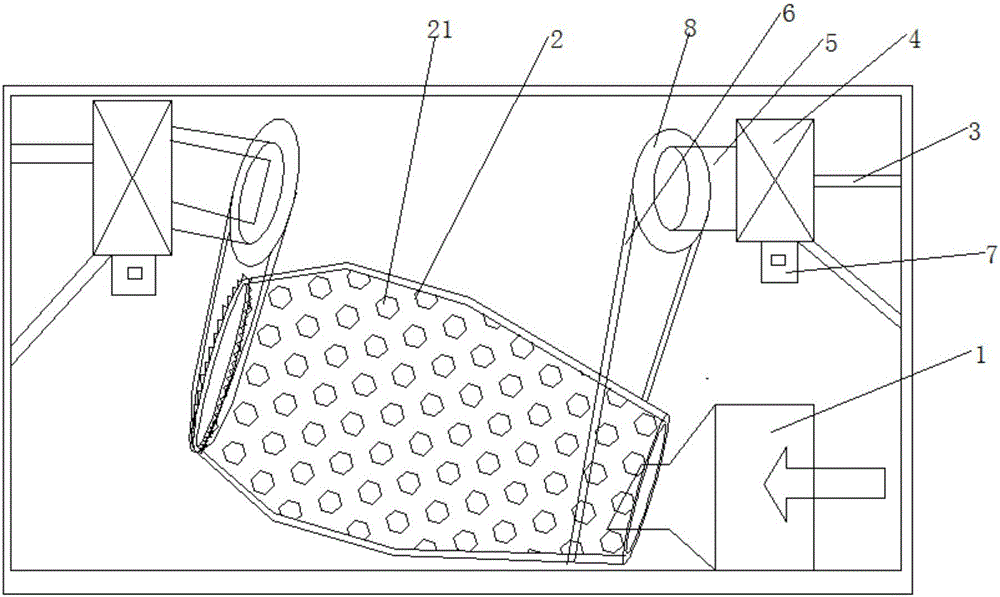

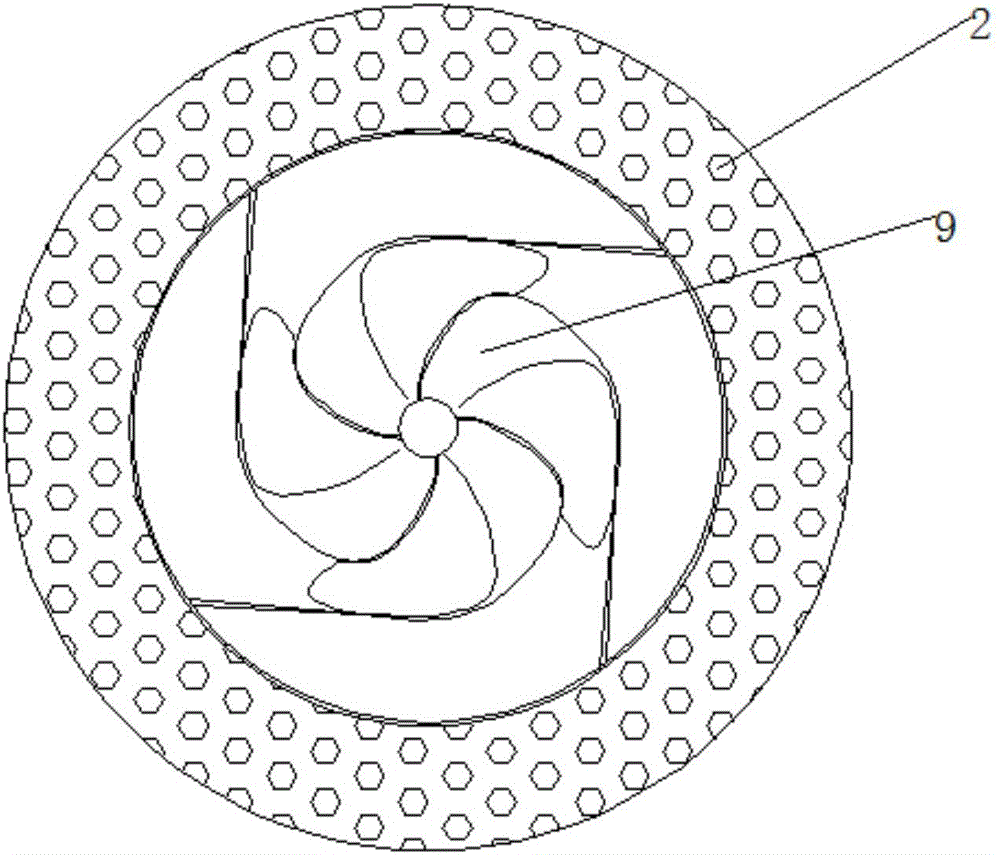

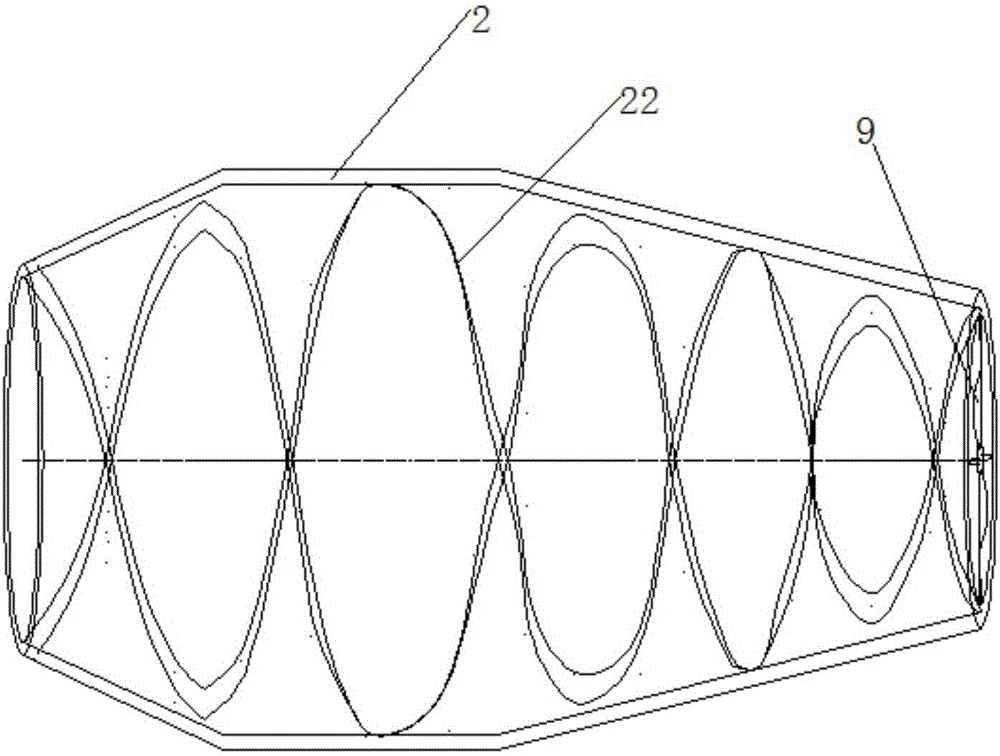

[0034] A garbage collection system in a water body, such as Figure 1-3 As shown, it includes a salvage collection device and a power source. The salvage collection device includes a frame 3 and a rotating salvage container fixed on the frame, wherein the rotary salvage container includes a controllable rotating internal hollow horizontal type tank structure 2, the horizontal tank structure 2 is inclined (the inclination angle is 15-60°, the inclination angle can be adjusted according to the actual working environment, preferably 30° in this embodiment), and its two ends are respectively equipped with feed inlet and discharge port, and a number of sieve holes are evenly opened on the side wall of the horizontal tank structure, and a propeller 9 is fixed at the entrance of the horizontal tank structure; the power source is arranged on the The horizontal tank structure is provided with the entrance of propeller 9, which is used to drive the propeller 9 and the tank body to rotat...

Embodiment 2

[0040] Such as Figure 4As shown, in this embodiment, the rotating disc and the rotating salvage container drive the rotating salvage container to rotate through gear meshing transmission, specifically: driven gears are provided on the outer sides of the two ends of the rotary salvage container, so The outer side of the rotating disc is provided with a driving gear meshed with the rotating salvage container, and the rotating disc and the rotating salvage container are driven through gear engagement; the horizontal tank structure of the rotating salvage container in this device is supported by a tugboat system, While playing a good supporting role, it can ensure that the rotating salvage container rotates relatively stably with the driving mechanism. Compared with the chain or conveyor belt transmission structure, the above structure is simpler and has better transmission effect.

[0041] The installation environment and specific usage method of the waste salvage and collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com