Tightening liquid injection type pipe opening plug

A nozzle and liquid injection technology, applied in the direction of pipe elements, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of difficulty in adjusting and re-tightening the seal, not suitable for multiple adjustments, etc., to increase the adhesion force , to avoid the effect of rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

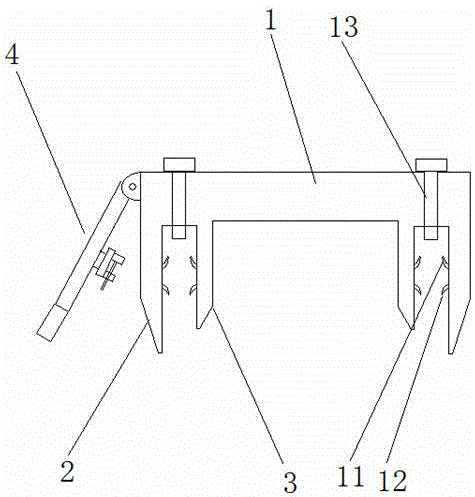

[0026] As shown in the figure, a tightening liquid injection nozzle plug of the present invention includes a tube plug, and the tube plug includes a cover body 1 and an outer wrapping surface 2 and an inner wrapping surface 3 wrapping the pipe wall;

[0027] The cover body 1 is provided with a lifting handle 4, one end of the lifting handle 4 is vertically hinged to the edge of the cover body 1, and the lifting handle 4 is provided with a rotating tightening device, generally the upper end is hinged, and the lower end is held for lifting. Further, the rotating tightening device is located in the middle of the lifting handle 4, and the principle of leverage is used when lifting, so it is only necessary to apply force easily, and it is more convenient to control the strength;

[0028] The outer wrapping surface 2 has a steel wire ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com