Front steering lamp for automobile

A front steering, automobile technology, applied in lampshades, motor vehicles, road vehicles, etc., can solve the problems of slow response speed, long response time, short service life, etc., to achieve lower energy consumption, improve performance, strong convergence The effect of light power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

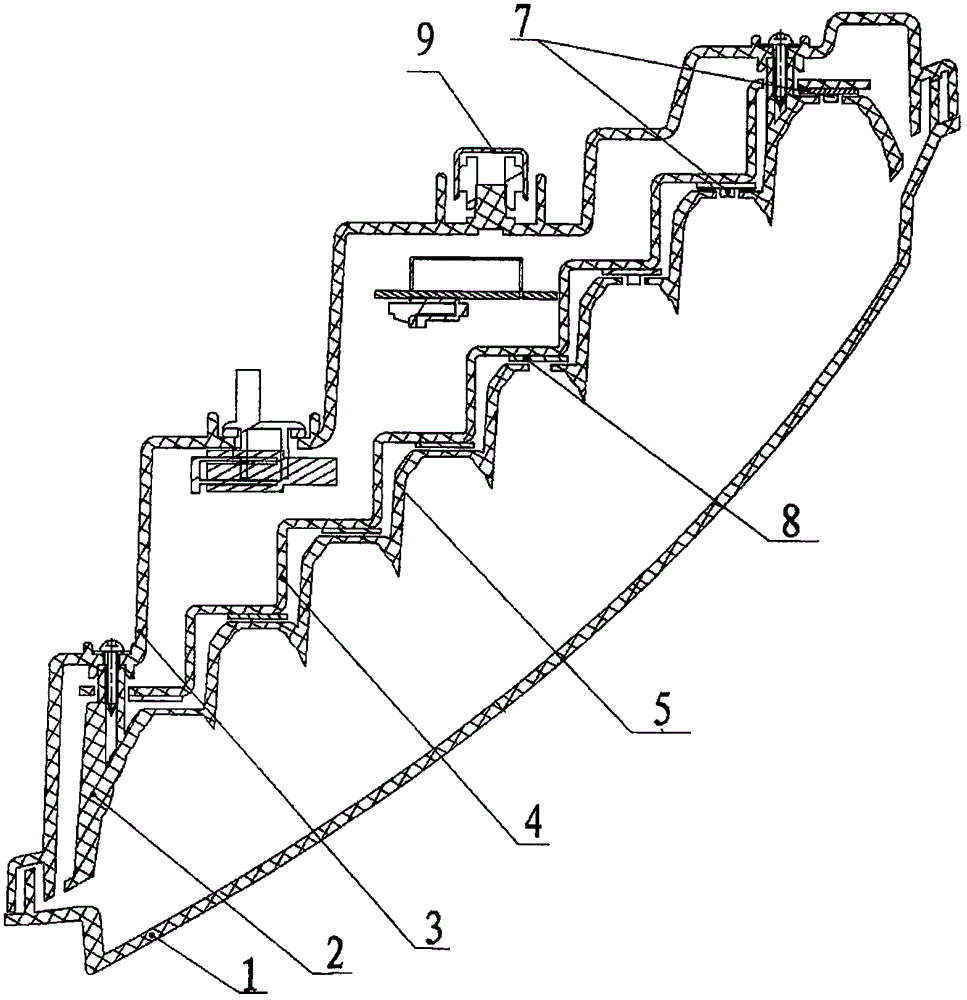

[0009] Depend on figure 1 Known, a kind of front turning lamp for automobile, comprises light distribution lens 1 and rear shell 3, and light distribution lens 1 and rear shell 3 are sealed and connected, and described rear shell 3 is also fixedly installed with spotlight cover 2, spotlight cover 2 is equipped with a stepped housing 4; it is characterized in that: the condenser cover 2 is provided with a plurality of paraboloids 5, and each parabolic surface 5 is provided with a light-emitting hole 6, and the stepped housing 4 is in the corresponding light-emitting hole 6 Each is provided with an LED light source 7, and the LED light source 7 is fixed on the aluminum substrate 8 and then fixed on the stepped shell 4. The stepped shell 4 is provided with a plurality of solder joints, and the positions of the solder joints correspond to the aluminum substrate 8. , the aluminum base plate 8 is fixed on the stepped housing 4 through solder joint welding, and the heat generated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com