Pulverized coal hot blast stove for drying grain

A hot blast stove and pulverized coal technology, which is applied in drying, dryer, grain drying, etc., can solve the problem of low coal burnout rate, low combustion efficiency, chain-row coal-fired hot blast stove cannot burn low-rank coal, lignite And other problems, to achieve the effect of improving economic benefits, complete combustion, and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

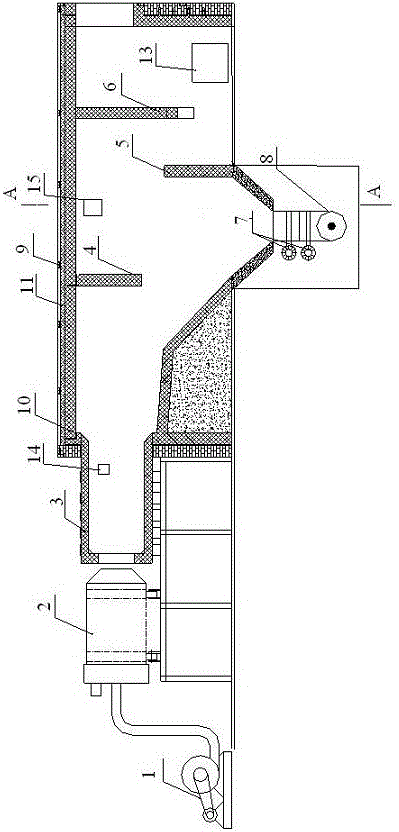

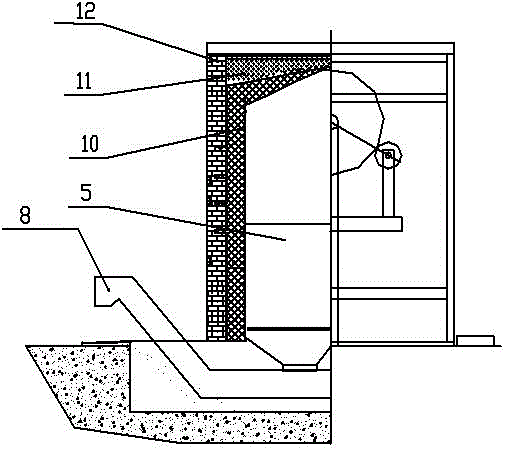

[0012] The pulverizer 1 is connected to one end of the cyclone pulverized coal burner 2, the other end of the cyclone pulverized coal burner 2 is connected to the combustion chamber 3, the combustion chamber 3 is connected to the furnace body 10, and the fire-retaining wall 4 and the fire-retaining wall 3 6 are respectively It is fixedly connected to the upper part of the furnace body 10, and there is an electric flashboard 7 under the ash chamber and the ash collecting hopper at the bottom of the combustion chamber. There is a screw conveyor 8 under the electric flashboard 7, and the second fire wall 5 is fixedly connected to the bottom of the furnace body 10. , the inspection port and the ash removal port 13 are located below the side of the furnace body, the air supply port one 14 is located at the side of the combustion chamber 3, and the air supply port two 15 is located at the upper side of the furnace body;

[0013] The furnace body 10 adopts refractory bricks;

[0014]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com