Method for measuring storage battery residual capacity SOC

A technology of remaining capacity and storage battery, applied in the direction of measuring electric variables, measuring electricity, measuring devices, etc., can solve the problem of large error accumulation of battery remaining capacity SOC calculation error and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

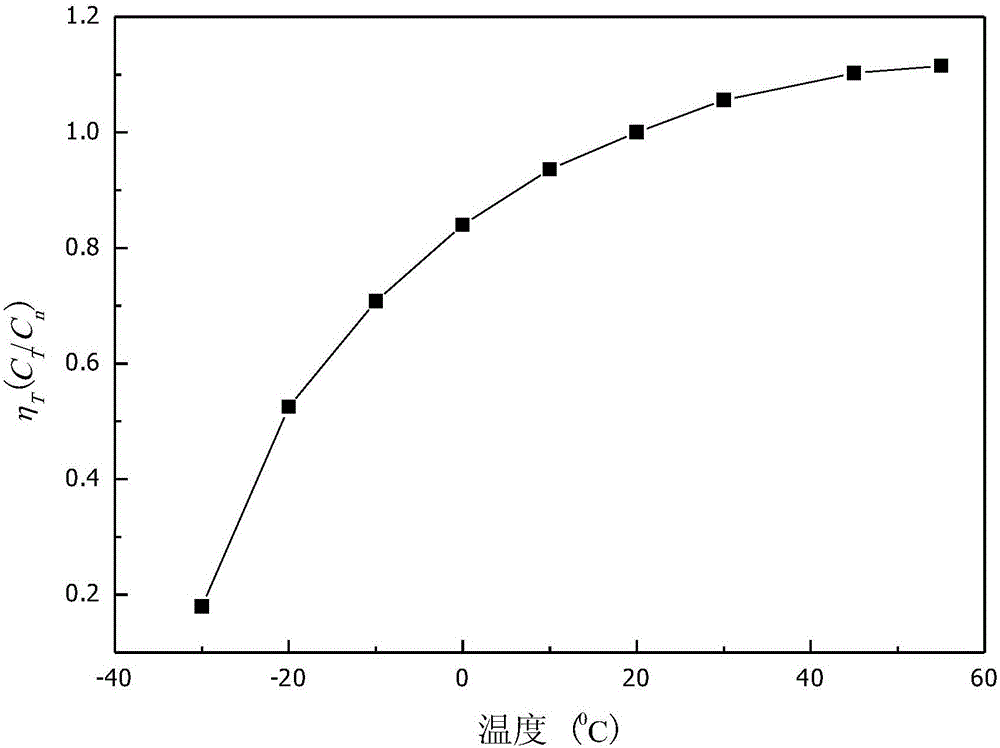

[0157] The mensuration of embodiment 1 accumulator attenuation coefficient

[0158] Take a newly manufactured lithium-ion power battery with a nominal 2.4V and a rated capacity of 10Ah. According to the detection method of the discharge capacity at 20°C in the automotive industry standard QC / T743-2006 "Lithium-ion Batteries for Electric Vehicles", according to the charging cut-off voltage is 2.75V, the discharge cut-off voltage is 1.5V, measure the actual capacity of the battery, and calculate the attenuation coefficient η according to formula (2) age . Then it was charged and discharged 10 times with the battery test system. The charging conditions were according to the charging system specified by the battery manufacturer, and the discharging was performed at a constant current of 20A for 35 minutes. Then measure the capacity of the storage battery according to the detection method of the discharge capacity at 20°C above and calculate the attenuation coefficient η age . C...

Embodiment 2

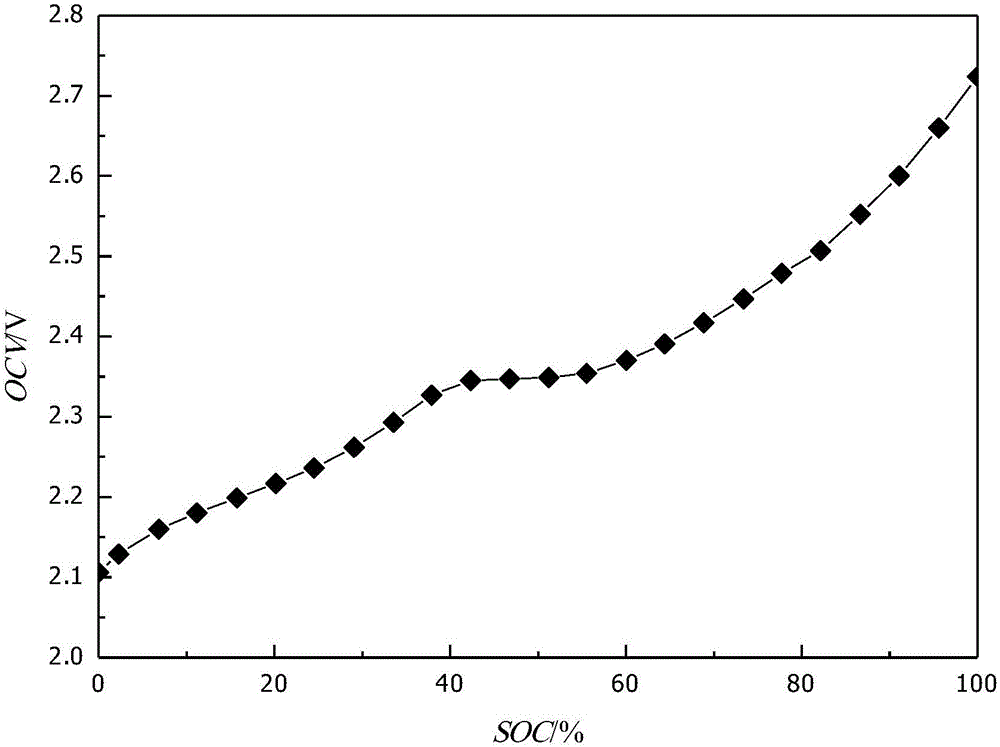

[0159] Battery SOC measurement results under the constant current discharge condition of embodiment 2

[0160] Take a lithium-ion power battery with a nominal 2.4V and a rated capacity of 10Ah, and charge and discharge cycles no more than 10 times. Conduct a 1C constant current discharge test in the electric vehicle laboratory at an ambient temperature of 20°C, and the discharge time is 30 minutes. , had been left to stand at ambient temperature for more than 2 hours before the experiment. The measured terminal voltage of the storage battery is 2.493V, and the SOC=80% corresponding to the OCV~SOC curve is checked. Take SOC 0 =80%, use two sets of completely identical BMS to monitor the battery discharge status simultaneously, and one set adopts the SOC measuring method provided by the present invention, because the battery cycle charge and discharge times are not more than 10 times, so it is desirable to take η age= 1.1; and take a 20-minute time period to calculate the aver...

Embodiment 3

[0161] Battery SOC measurement results under the condition of variable current discharge in embodiment 3

[0162] Take a lithium-ion power battery with a nominal 2.4V, a rated capacity of 10Ah, and a fully charged lithium-ion power battery that has been charged and discharged 200 times in the electric vehicle laboratory. See the table below for current and duration. Monitor the discharge situation of storage battery simultaneously with two sets of completely identical BMS, one set adopts the SOC measurement method that the present invention provides, gets η age =1.0; and take a 30s time period to calculate the average capacity correction coefficient. All parameters are automatically taken by BMS according to the real-time measured temperature and discharge current data and used for SOC calculation.

[0163] serial number

[0164] After the discharge, the method provided by the present invention finally shows SOC=36.7%; the traditional ampere-hour integration method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com