A method and system for multi-model collinear production management

A production management system and production management technology, which are applied in the field of multi-model collinear production management methods and systems to achieve the effects of enhancing the flexibility of the line body and reducing the probability of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

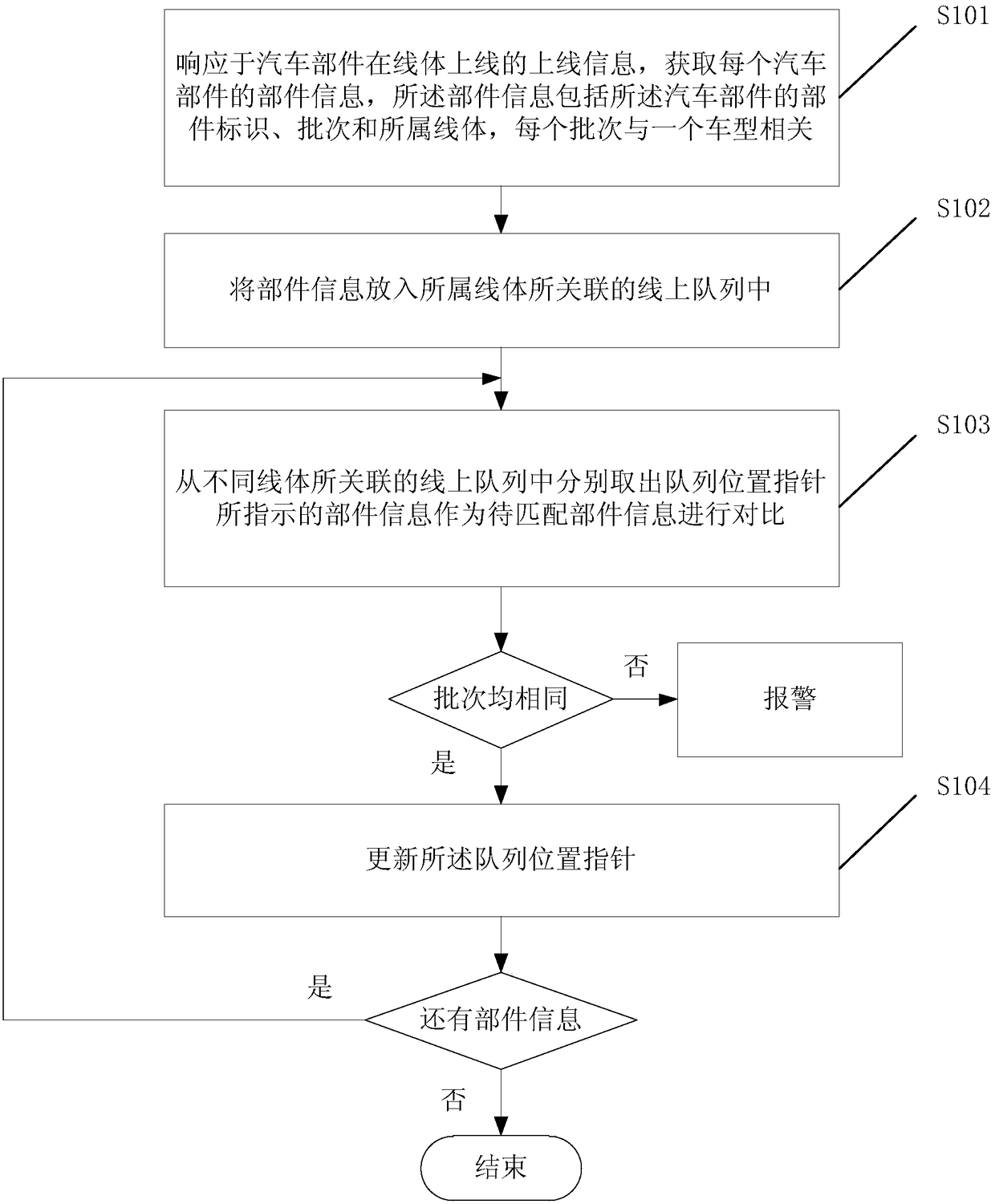

[0021] Such as figure 1 Shown is a work flow diagram of a multi-vehicle collinear production management method of the present invention, including:

[0022] Step S101, including: in response to the on-line information of the online body of the auto part, obtain the part information of each auto part, the part information includes the part identification, batch and line body of the auto part, and each batch is related to related to a model;

[0023] Step S102, including: putting the component information into the online queue associated with the line body to which it belongs;

[0024] Step S103, including: taking out the component information indicated by the queue position pointer from the online queues associated with different line bodies as the component information to be matched for comparison, and if the batches included in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com