LED glue preparation control system and method

A technology of a control system and a manufacturing method, applied in measuring devices, instruments, weighing and other directions, can solve the problems of inability to meet the cost reduction of LEDs, human error in data, wrong use of materials, etc., so as to reduce human judgment links and solve human errors. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

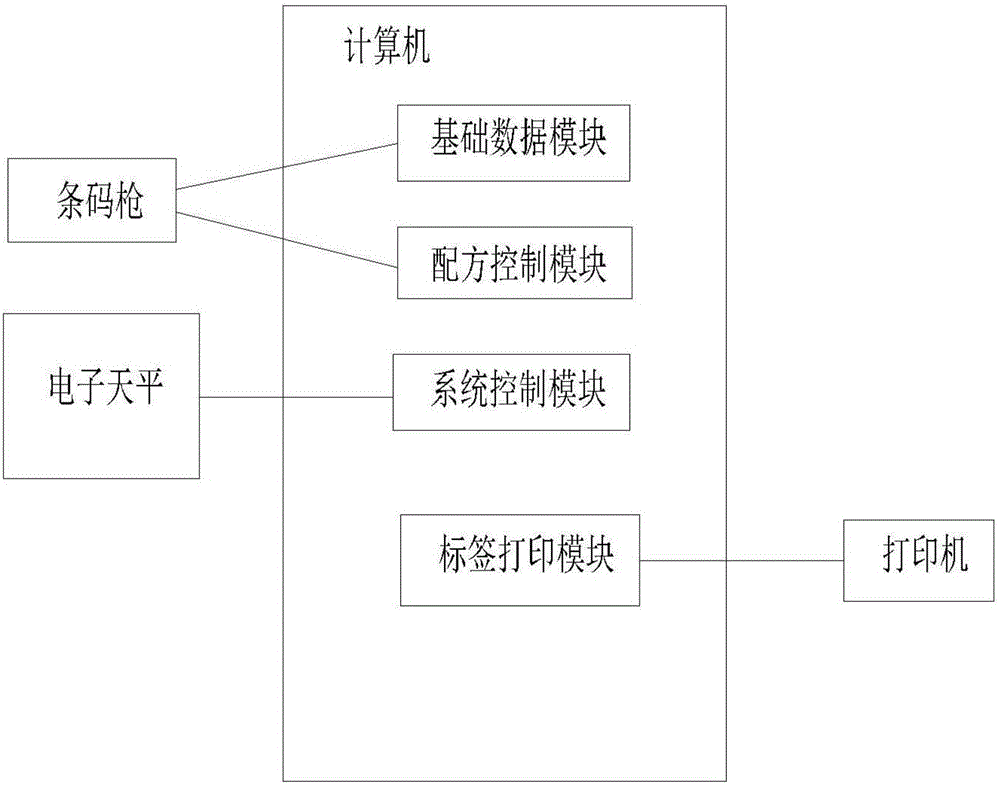

[0033] 1. The control system has a basic data module (entry, maintenance), recipe control module, recipe data recording module, label printing module, data query and report module, and system control module; currently, 3 computers and 5 precision electronic balances have been configured. Taiwan, 3 printers, 5 sets of marble platforms; location: glue distribution room of the production workshop; the construction software control system is connected with the precision electronic balance, and the software can be used to read and control the data and accuracy weighed by the balance, and at the same time, the printer can be controlled to realize Print to distinguish different batches to avoid confusion.

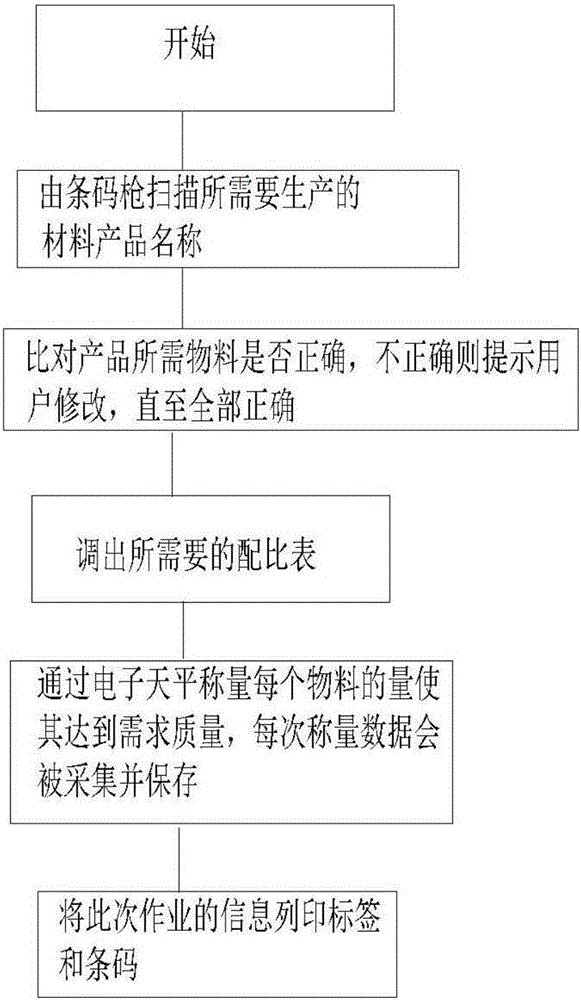

[0034] 2. The control system scans the barcode of each material and automatically compares it with the existing material barcode in the formula table. If it is inconsistent, an alarm will be prompted. The staff enters the reference weight, which is automatically calculated accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com