Patents

Literature

34results about How to "Reduce human judgment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

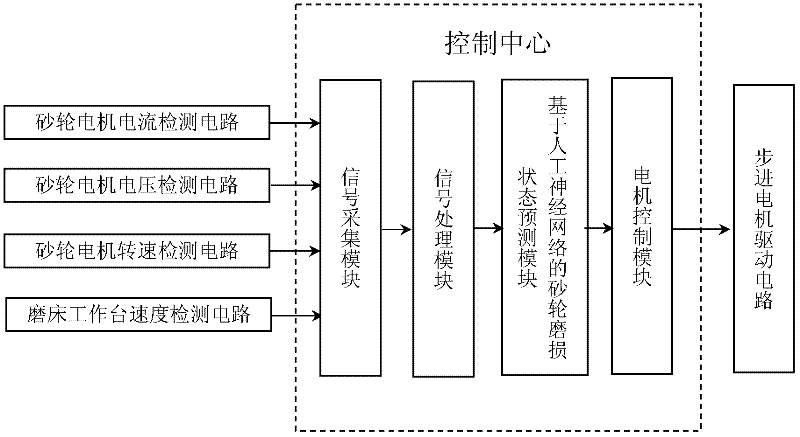

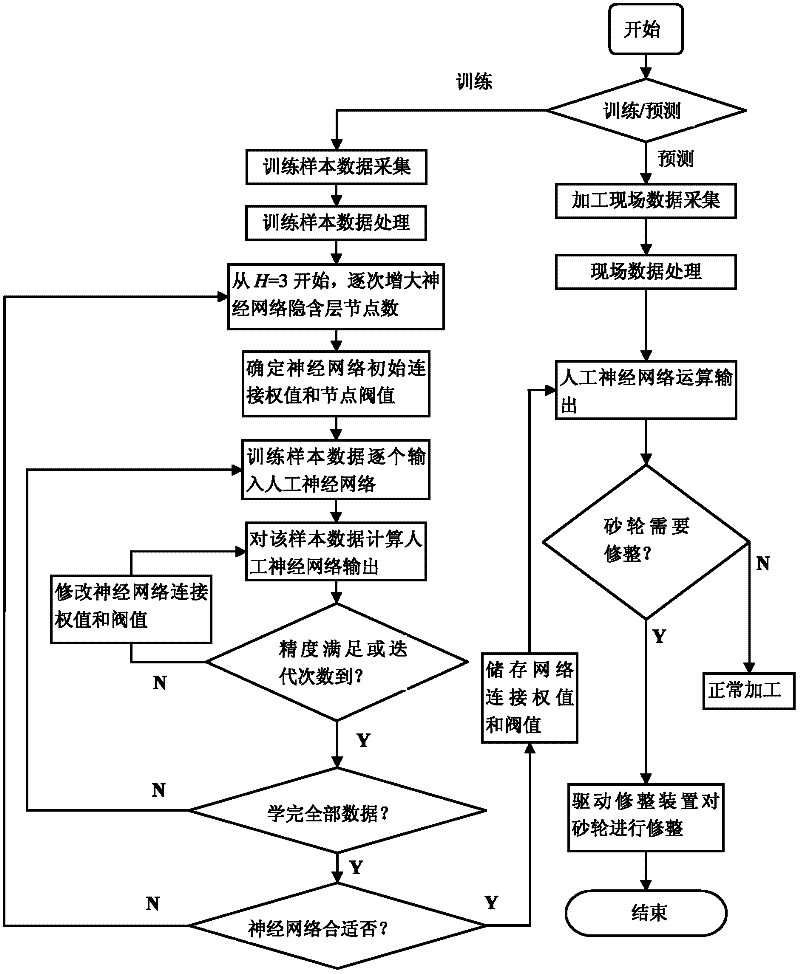

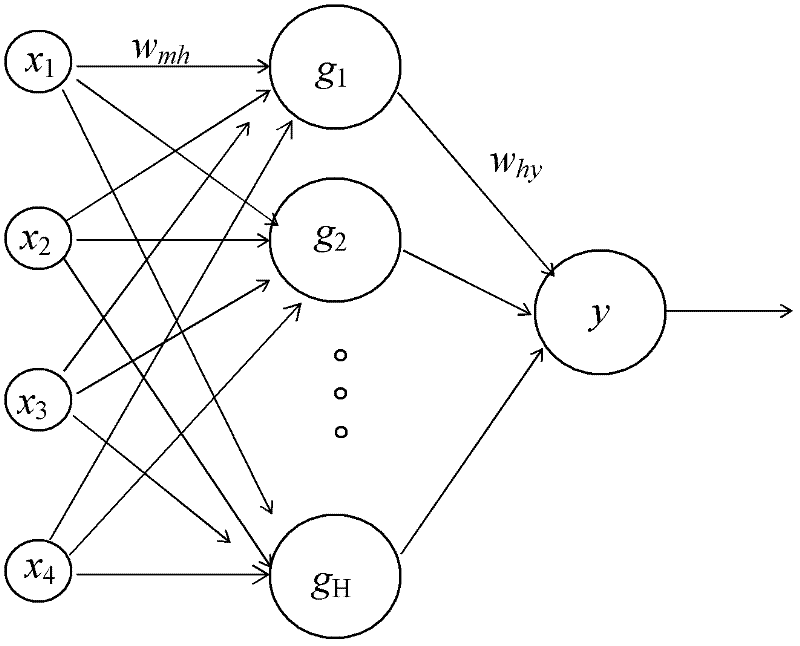

Artificial neural network-based method and device for automatically trimming grinding wheel of grinding machine

InactiveCN102335872ARealize automatic trimmingAutomatic trimming easyAbrasive surface conditioning devicesNumerical controlGrinding wheelMachining

The invention discloses an artificial neural network-based method and a device for automatically trimming a grinding wheel of a grinding machine. The method comprises the following steps: collecting data, i.e. the voltage U of a grinding wheel motor, the current I of the grinding wheel motor, the revolving speed n of the grinding wheel, the relative translational velocity v of parts to be machined and the grinding wheel, and the passivation coefficient d of the grinding wheel corresponding to each experiment, from the experiment field at each experiment through evenly-grinding experiments; selecting training sample data from the data to train the built artificial neural network prediction model; and sending data in the built artificial neural network prediction model to calculate an output y after collecting the data on site, i.e. the voltage U of the grinding wheel motor, the current I of the grinding wheel motor, the revolving speed n of the grinding wheel and the relative translational velocity v of the parts to be machined and the grinding wheel, and comparing the y with a preset trimming set value so as to control a trimming device to trim the grinding wheel. With the adoption of the method and the device disclosed by the invention, the artificial judging factors in grinding and machining can be reduced, so that the degree of automation of the grinding machine in the processes of grinding and machining is enhanced, and the cost for machining and the rejection rate are reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

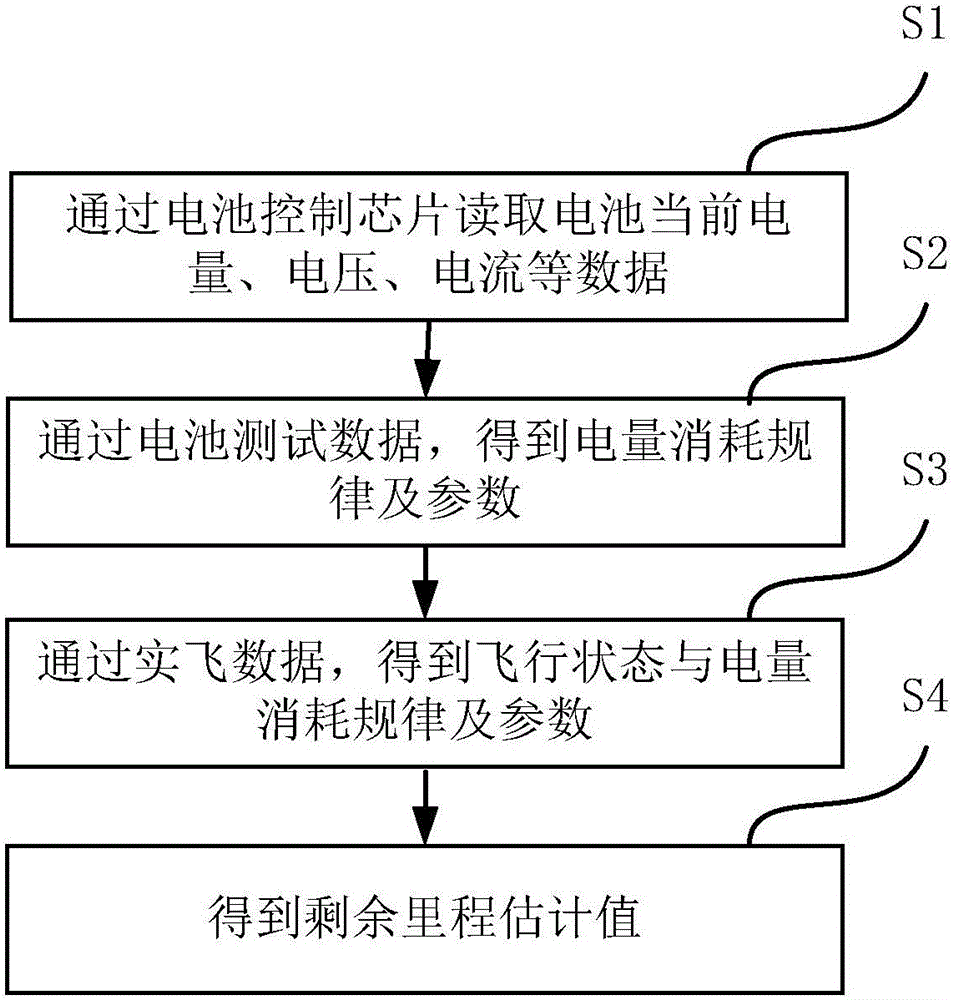

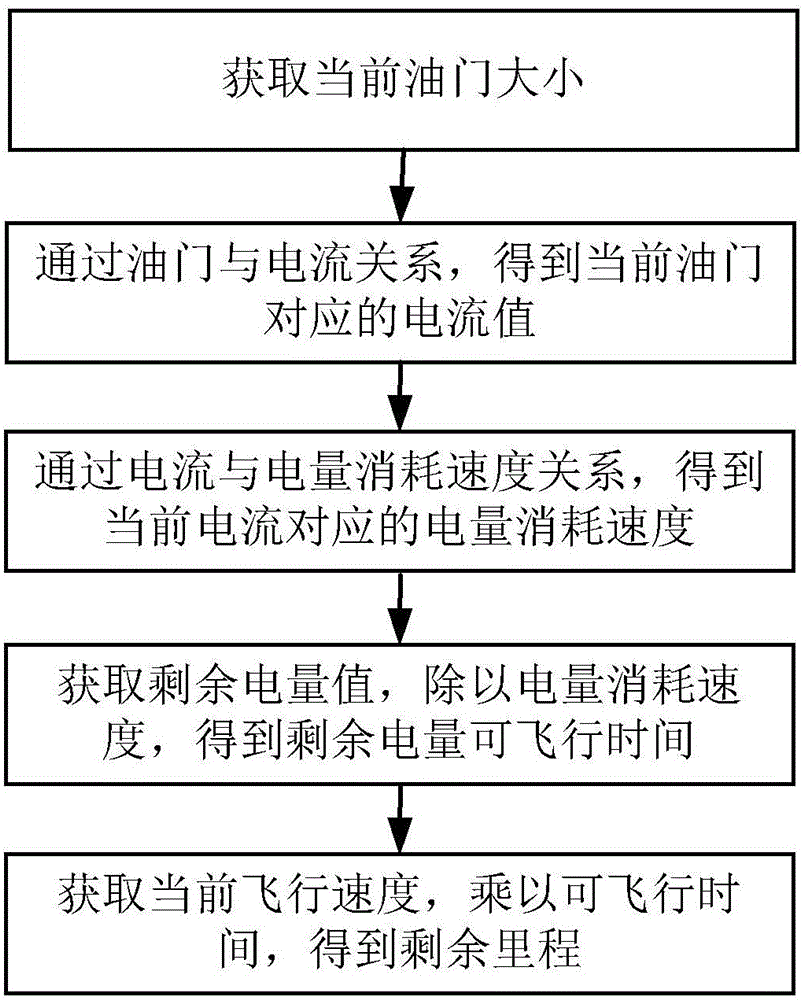

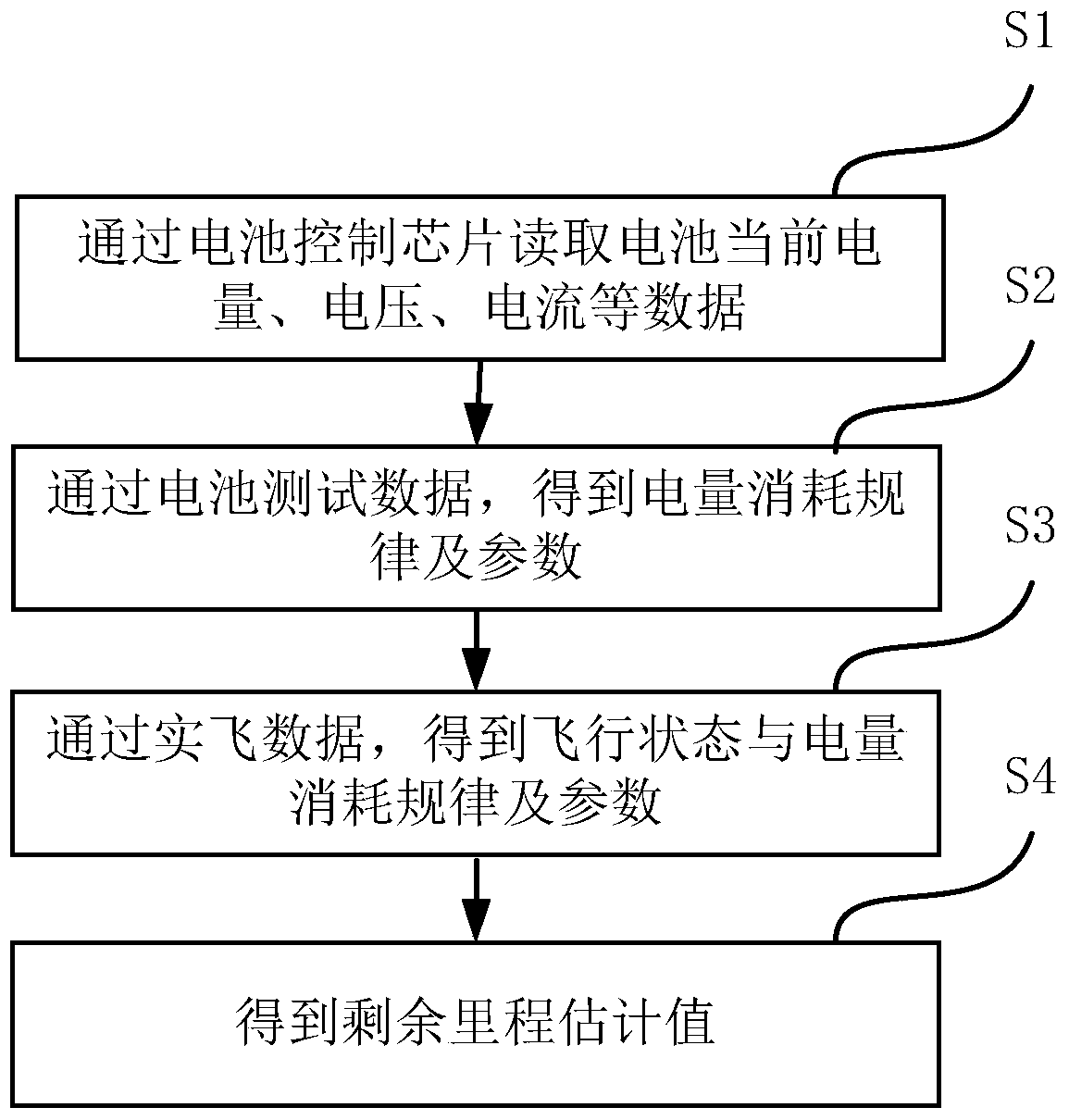

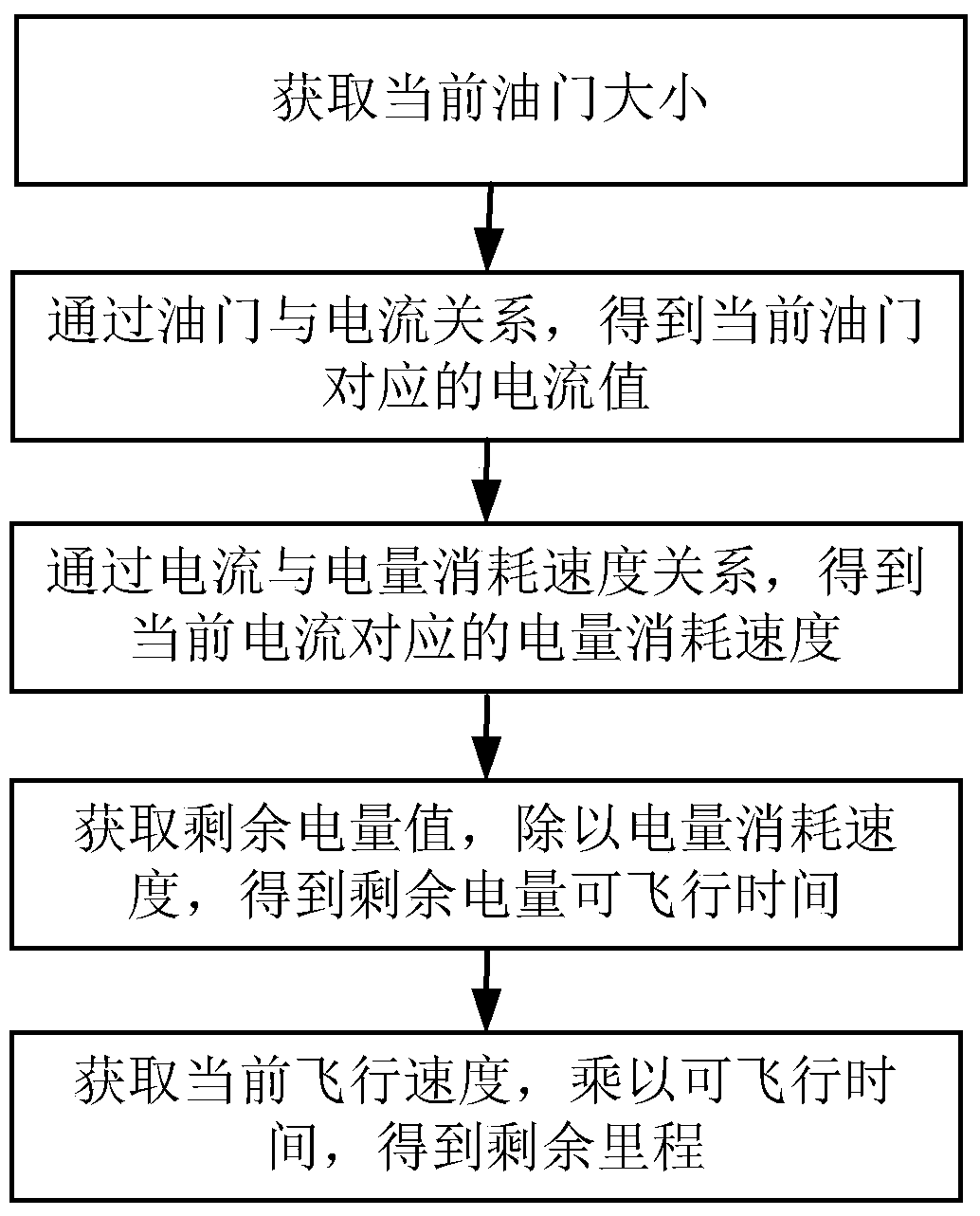

Electric UAV remaining mileage estimation method

ActiveCN105759218AReduce difficulty of useReduce human judgmentElectrical testingSimulationCollaboration

The invention discloses an electric UAV remaining mileage estimation method comprising a step S1 of reading out current battery test data including the electric quantity, voltage and current of a battery through a battery control chip; a step S2 of obtaining electric quantity consumption laws parameters through the battery test data; a step S3 of obtaining laws and parameters between flight states including the flight speed and distance and electric quantity consumption through actual flight data; and a step S4 of calculating a remaining mileage estimated value. The invention can calculate the remaining flight mileage in real time according to the electric quantity of the battery; thus, can reduce human judgment and reduce difficulty in using UAVs; and can automatically calculate the flight distance through an algorithm, and can perform UAV flight operation without multi-user collaboration.

Owner:天津飞马机器人科技有限公司

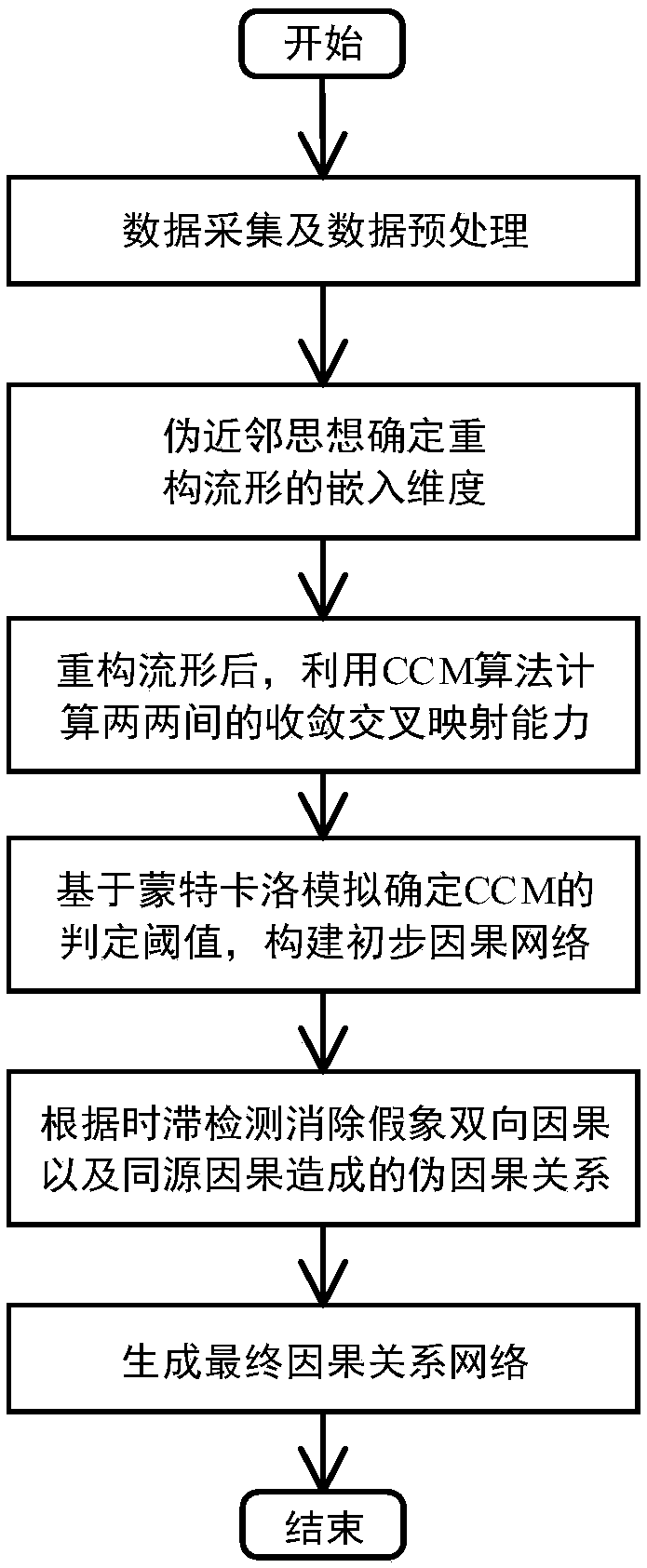

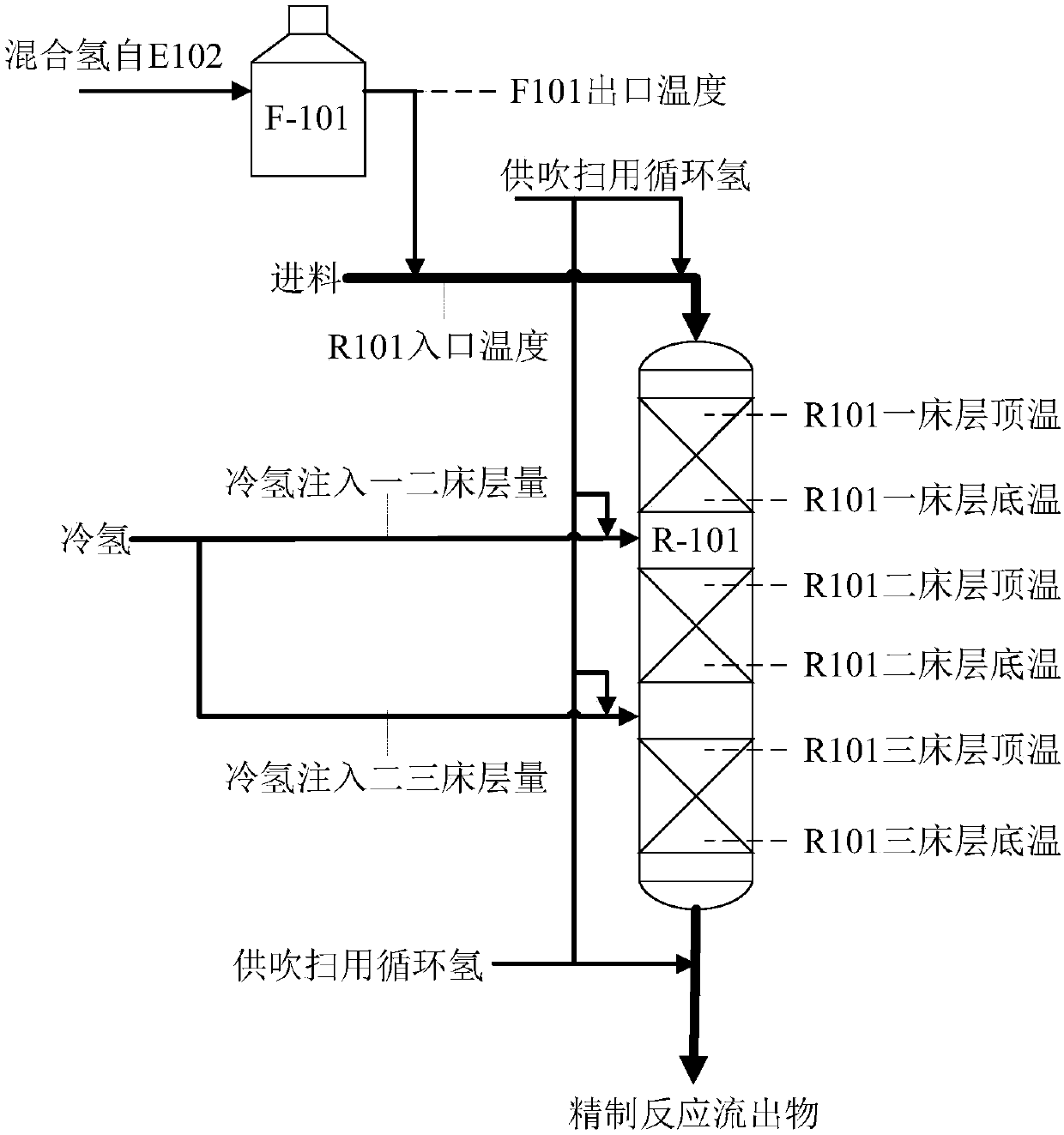

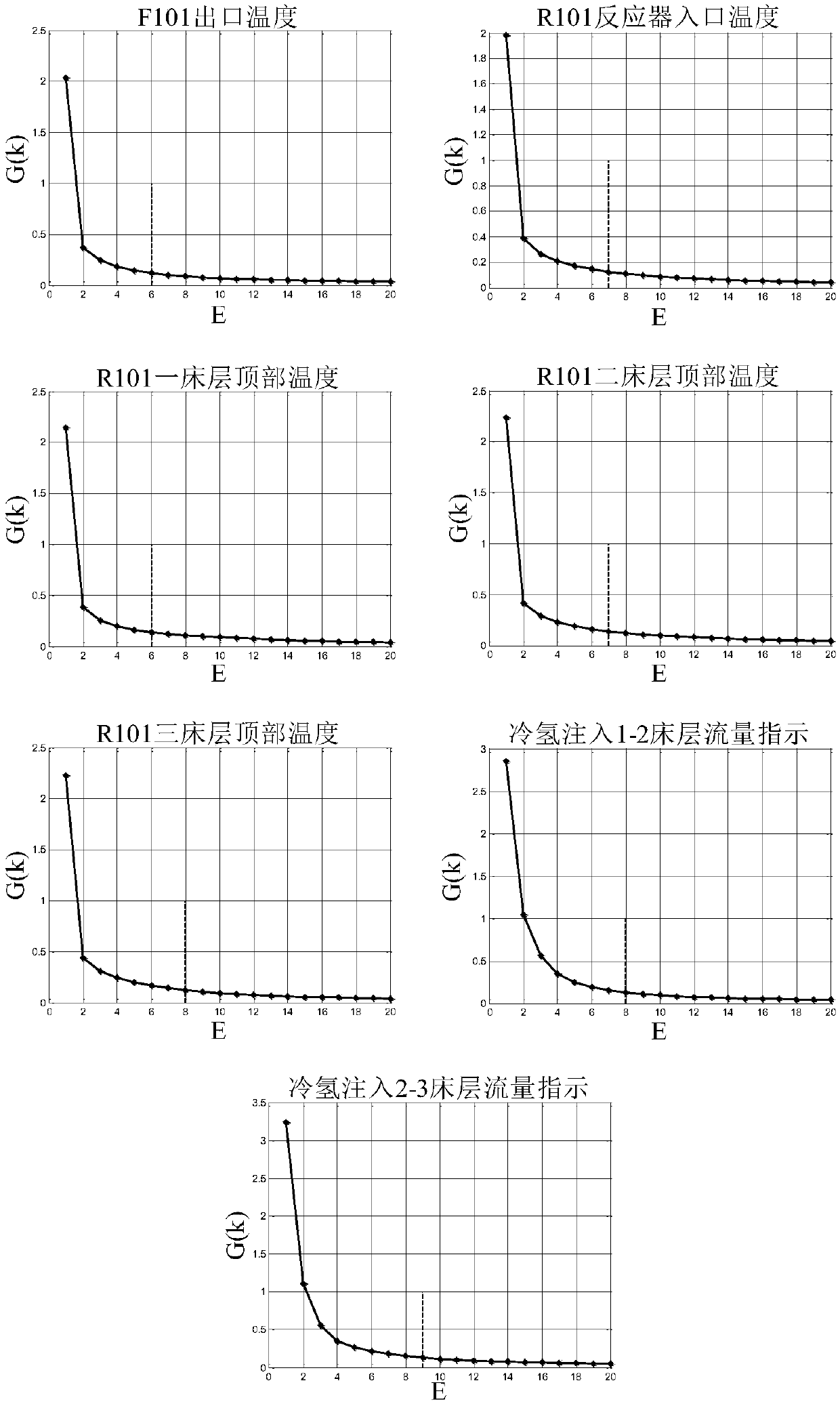

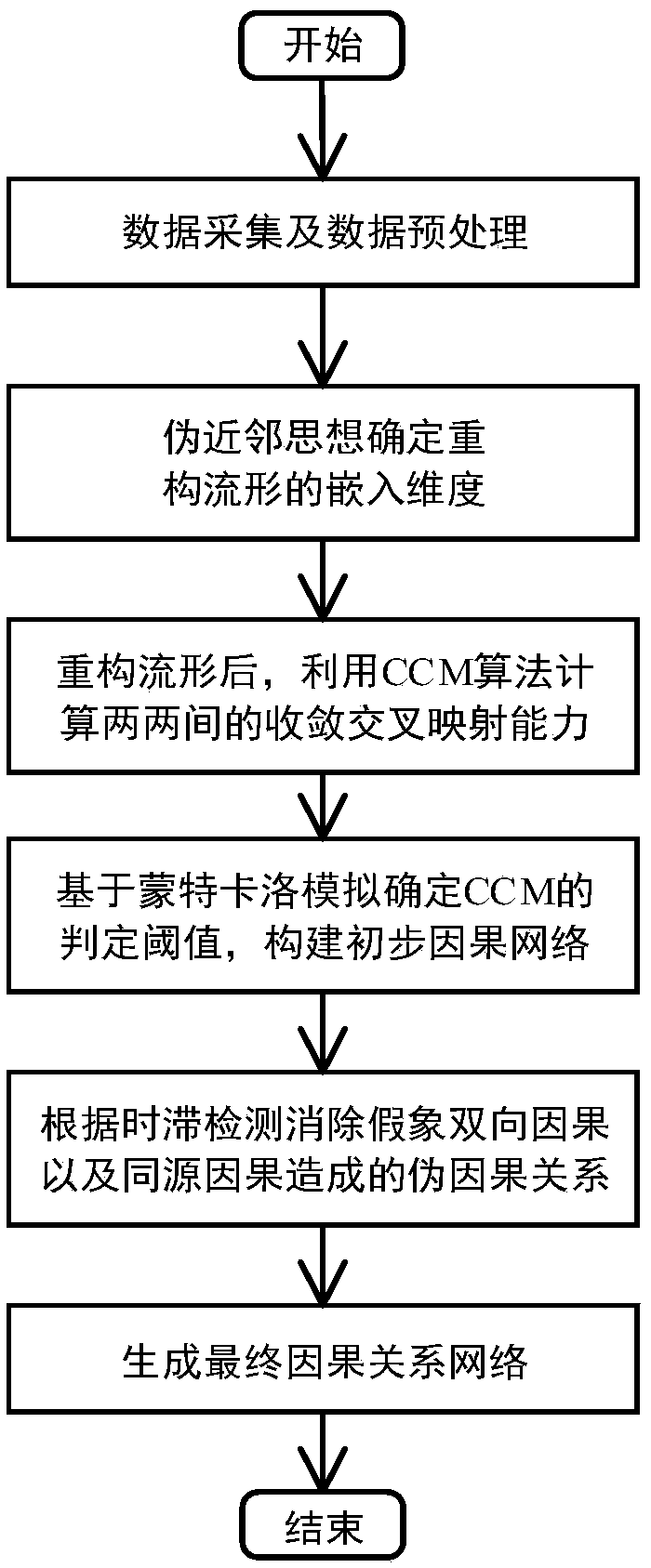

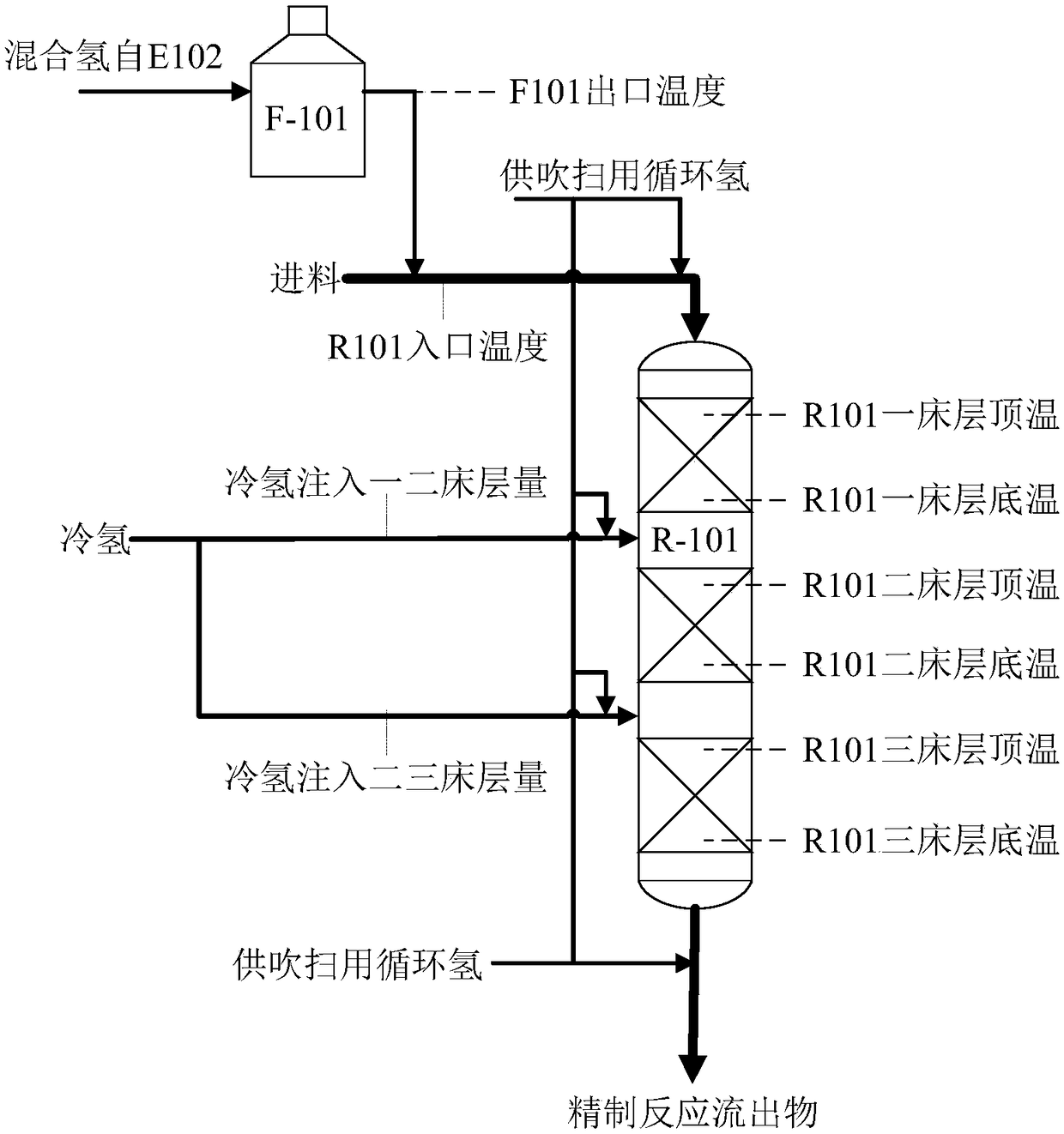

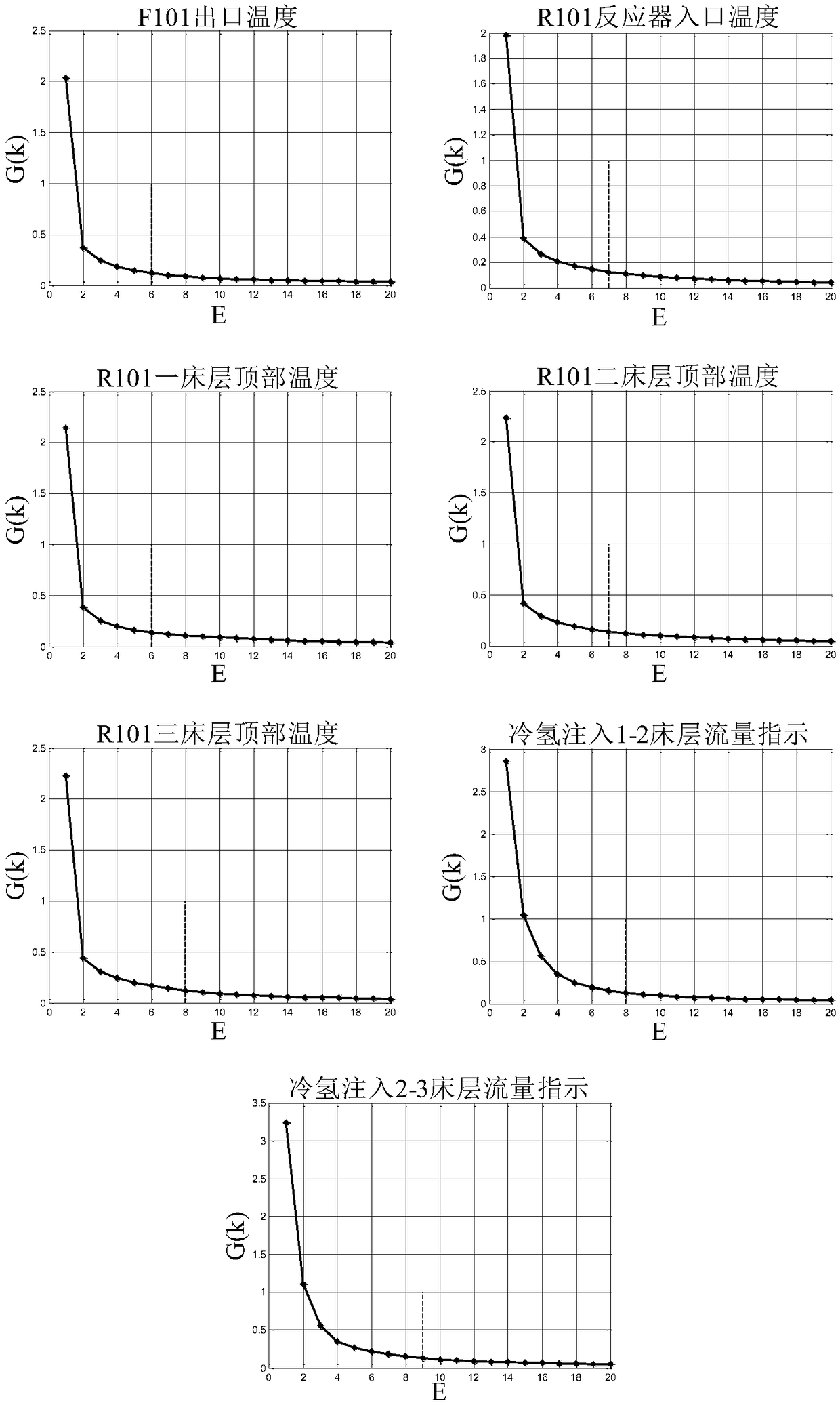

Method for determining causal relationship of key variables in complex industrial process

ActiveCN108171142ALow resolution accuracyTake advantage ofCharacter and pattern recognitionComplex mathematical operationsTime lagConvergent cross mapping

The invention discloses a method for determining the causal relationship of the key variables in a complex industrial process. The optimal time sequence embedding dimension of each key variable is calculated through the pseudo-neighbor thought according to the historical data of the key variables of the causal relationship to be determined in the industrial process; for the two key variables, thecausal relationship is assumed, so that the optimal time sequence embedding dimension of the factor is assumed to be the standard, and a time sequence reconstitution flow shape of the two key variables is constructed, a convergence cross mapping algorithm is used for calculating the convergence cross mapping capability between the two; the capability judgment threshold value of the CCM is determined based on Monte Carlo simulation, so as to judge the correctness of the assumed causal relationship among the key variables, so as to construct a preliminary causal relationship network of the key variables in the industrial process; and a time lag detection method is used for correcting a preliminary causal relationship network to obtain a final key variable causal relationship network. According to the method, the offline data is fully utilized, so that the interference effect on the production process is avoided, and the safety and the economic benefit are improved.

Owner:CENT SOUTH UNIV

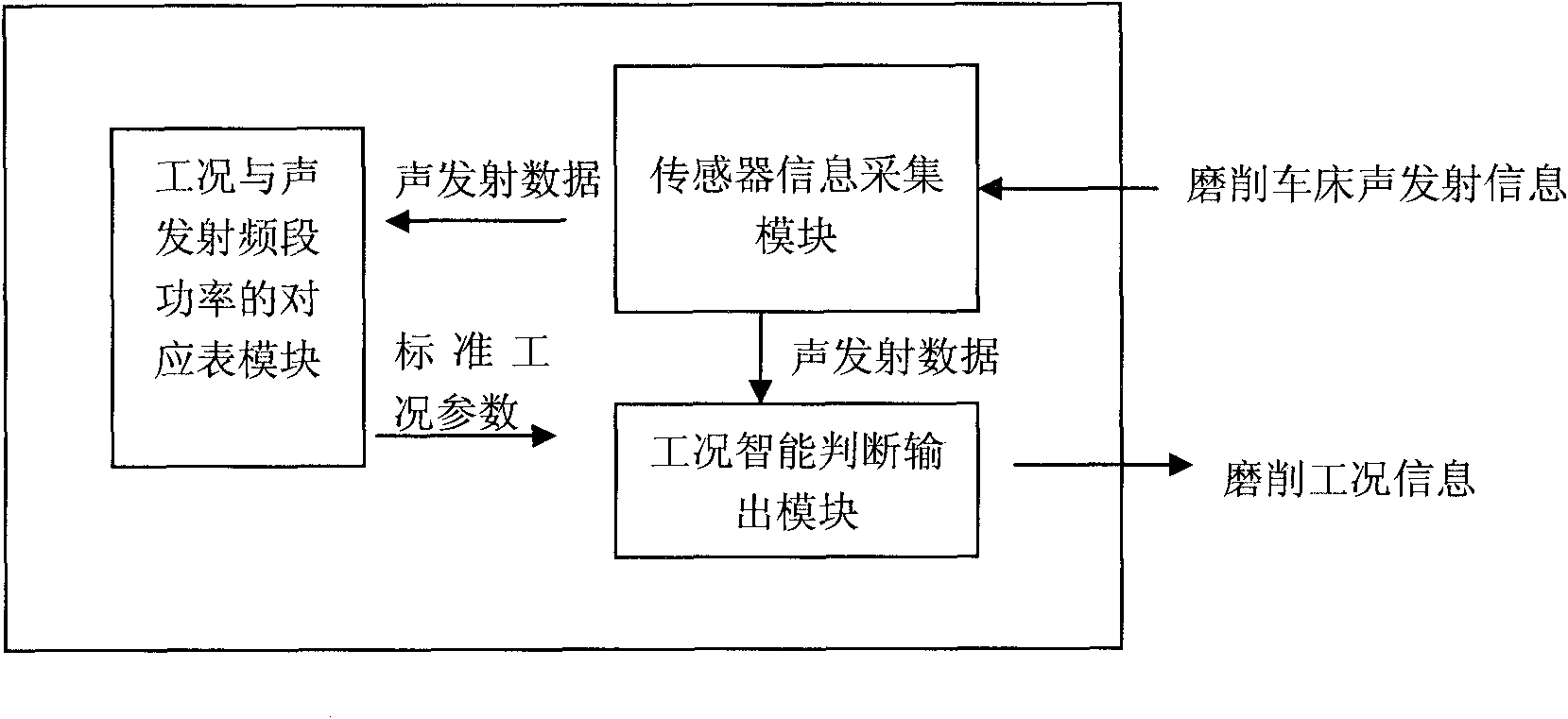

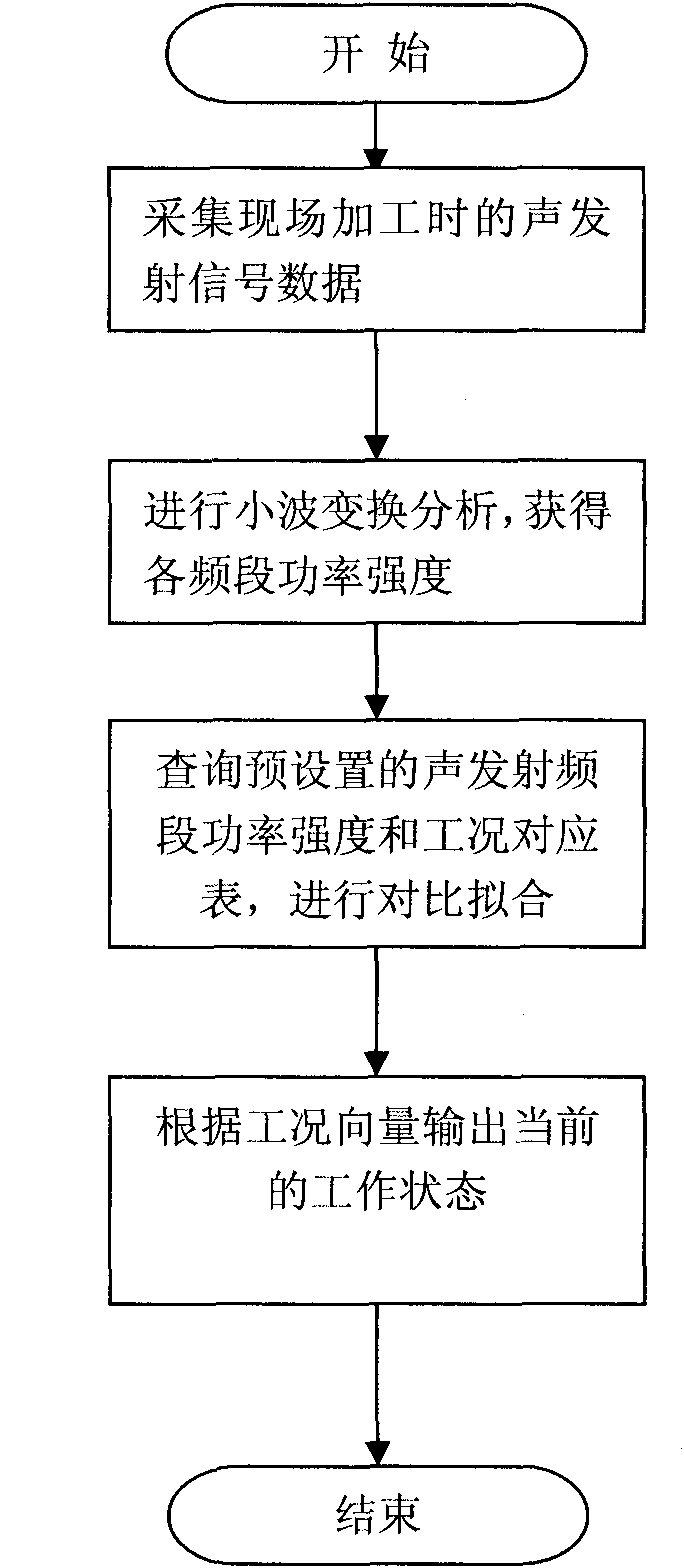

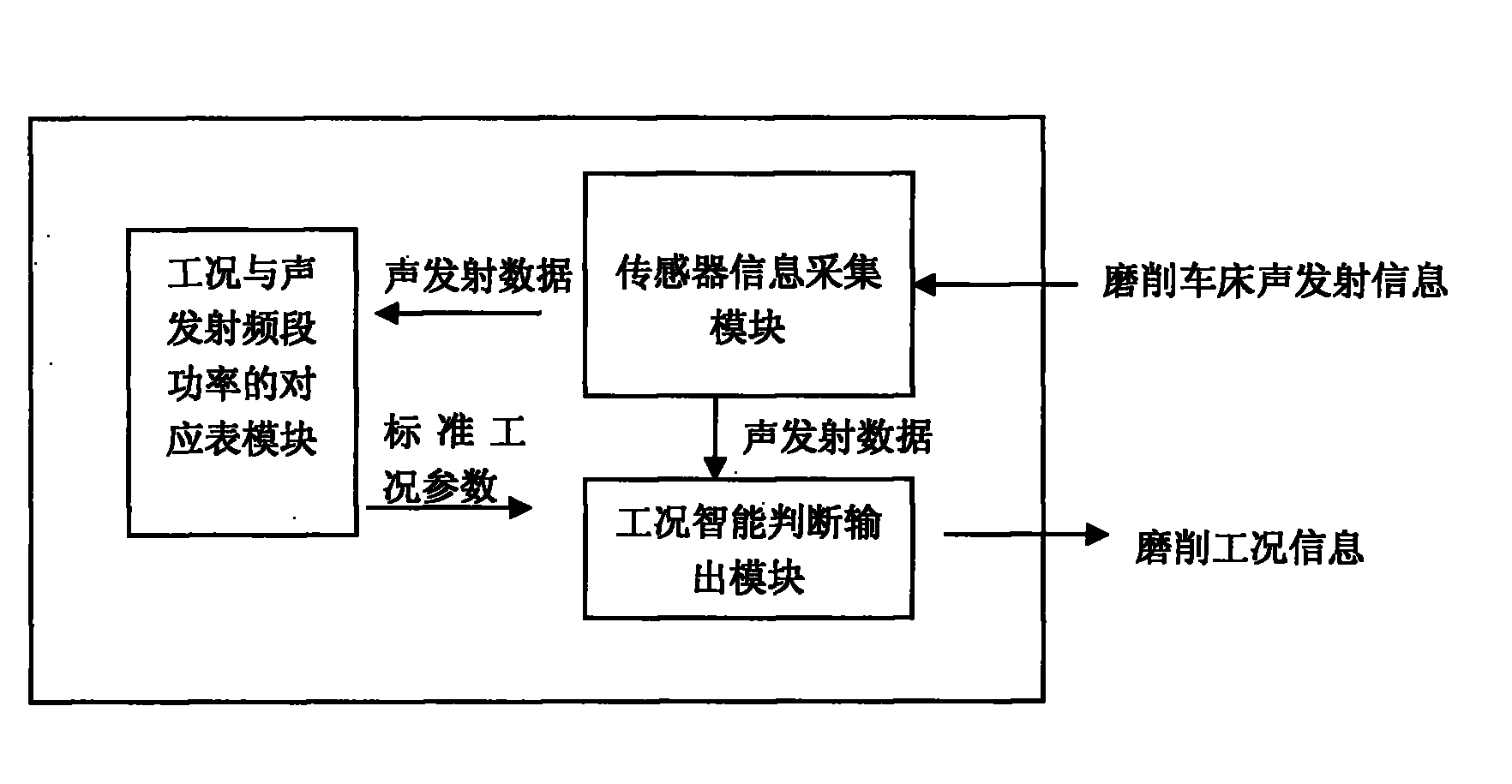

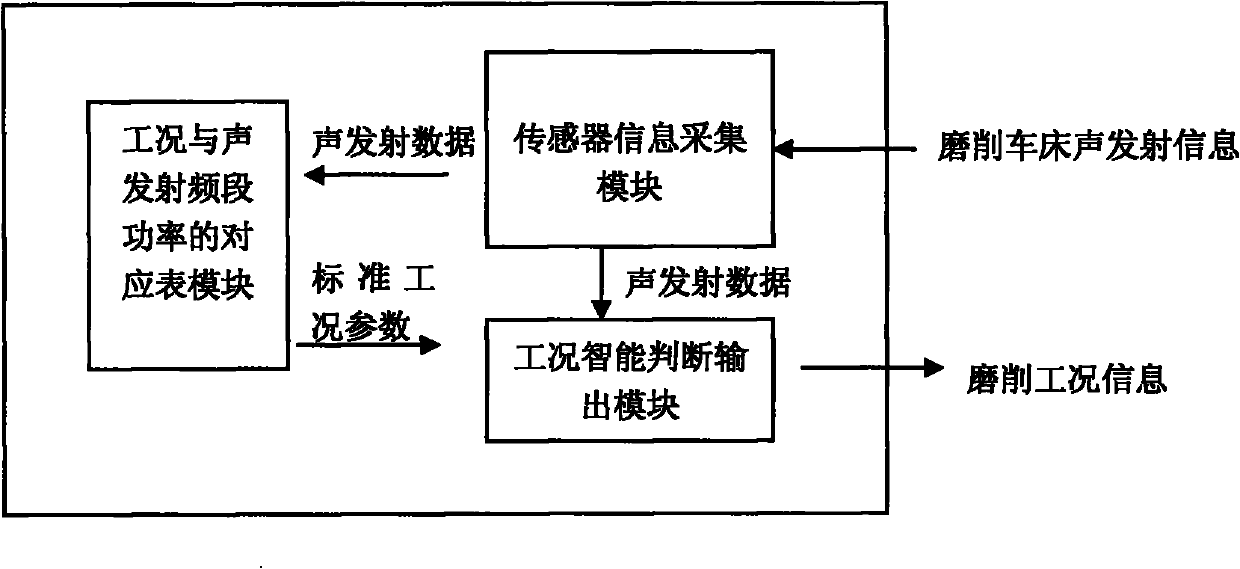

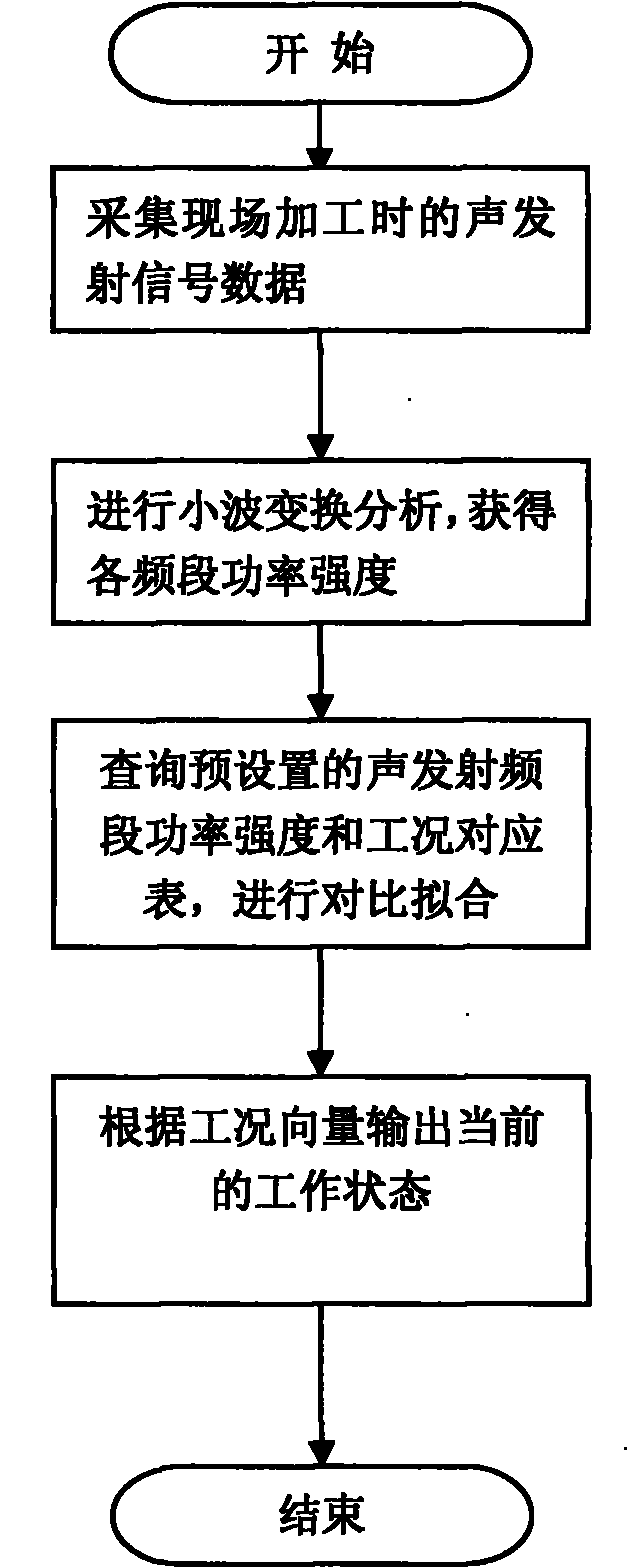

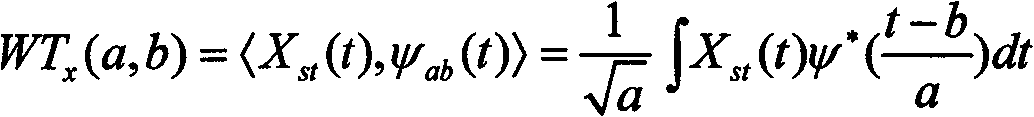

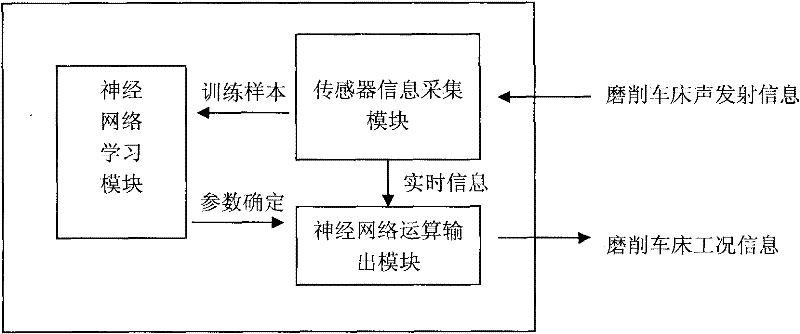

Wavelet analysis-based grinding machining working condition detection system and method thereof

ActiveCN101819119AAvoid damageQuickly and automatically judge the processing statusSubsonic/sonic/ultrasonic wave measurementInvestigating machinabilityAcoustic emissionWavelet transform analysis

The invention discloses a wavelet analysis-based grinding machining working condition detection system and a wavelet analysis-based grinding machining working condition detection method. The system comprises a sensor information acquisition module, a corresponding table module for working conditions and acoustic emission frequency band power, and an intelligent working condition judgment and output module. An acoustic emission sensor is arranged on a grinding machine and transmits acoustic emission signals to the corresponding table module for the working conditions and the acoustic emission frequency band power and the intelligent working condition judgment and output module respectively; the corresponding table module for the working conditions and the acoustic emission frequency band power acquires the standard power intensity of each frequency band by using a wavelet transformation analysis method, and constructs a corresponding table between standard working conditions and standard acoustic emission frequency band power intensity Pst; and the intelligent working condition judgment and output module performs wavelet transformation analysis on the acoustic emission signals to acquire current power intensity, matches the current power intensity with the Pst, calculates a fit error value and determines and outputs a current grinding working condition.

Owner:NANJING UNIV +1

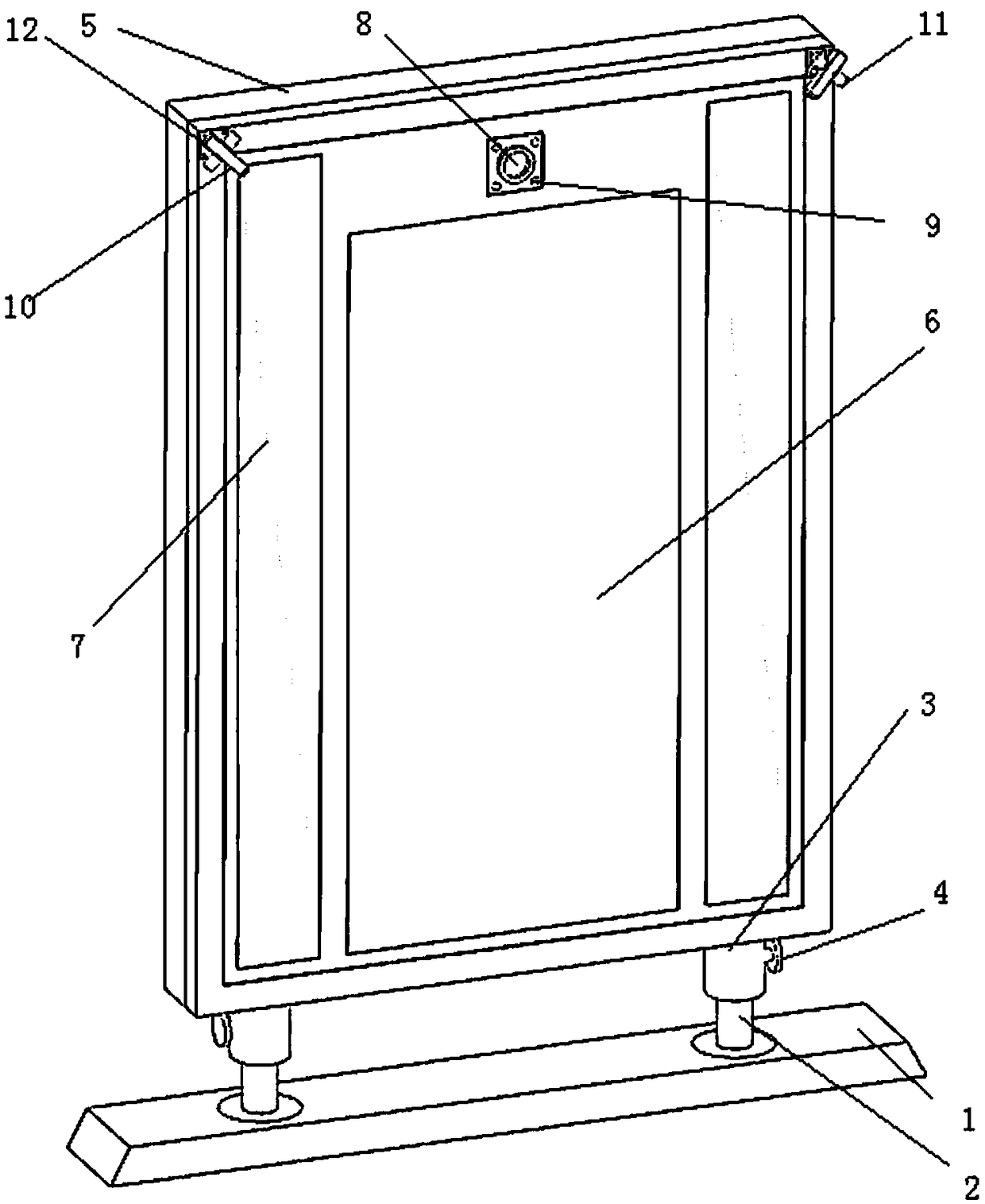

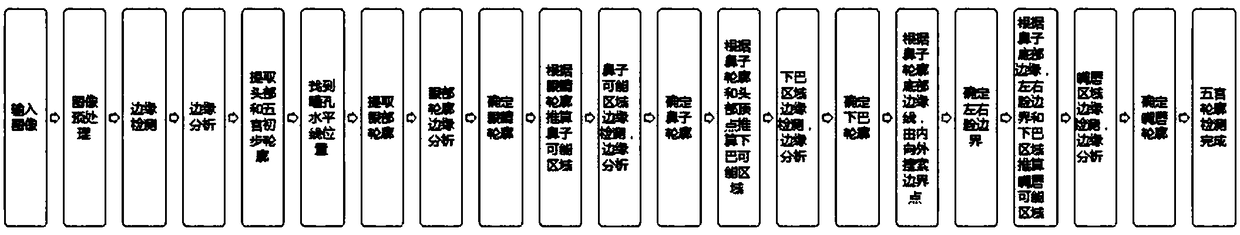

Interactive cosmetic mirror and working method thereof

PendingCN108402643ASimple and fast operationReduce human judgmentCharacter and pattern recognitionShaving accessoriesLED displayInductor

The invention provides an interactive cosmetic mirror. The mirror comprises a base, a mounting rack, a main cosmetic mirror body, an LED display screen, interactive buttons, a scanning camera, infrared positioning inductors and movable fill-in lights; the main cosmetic mirror body is fixed to the base through the mounting rack, the LED display screen and the interactive buttons are arranged at thefront side of the main cosmetic mirror body, and a row of interactive buttons are arranged at each side of the LED display screen; the scanning camera is arranged above the LED display screen, the infrared positioning inductors are arranged at the four corners of the scanning camera respectively, and the movable fill-in lights are arranged at the two corners of the upper portion of the main cosmetic mirror body respectively. According to the interactive cosmetic mirror and a working method thereof, a user stands in front of the interactive cosmetic mirror, the camera on the cosmetic mirror identifies the face of the user, then modelling is conducted, judgment and matching are conducted according to a database to obtain good results, and the results are displayed on the interactive screenfor the user to select and use.

Owner:许峰

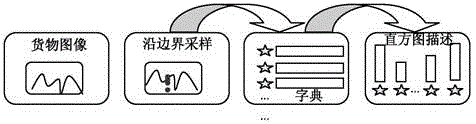

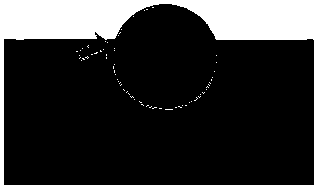

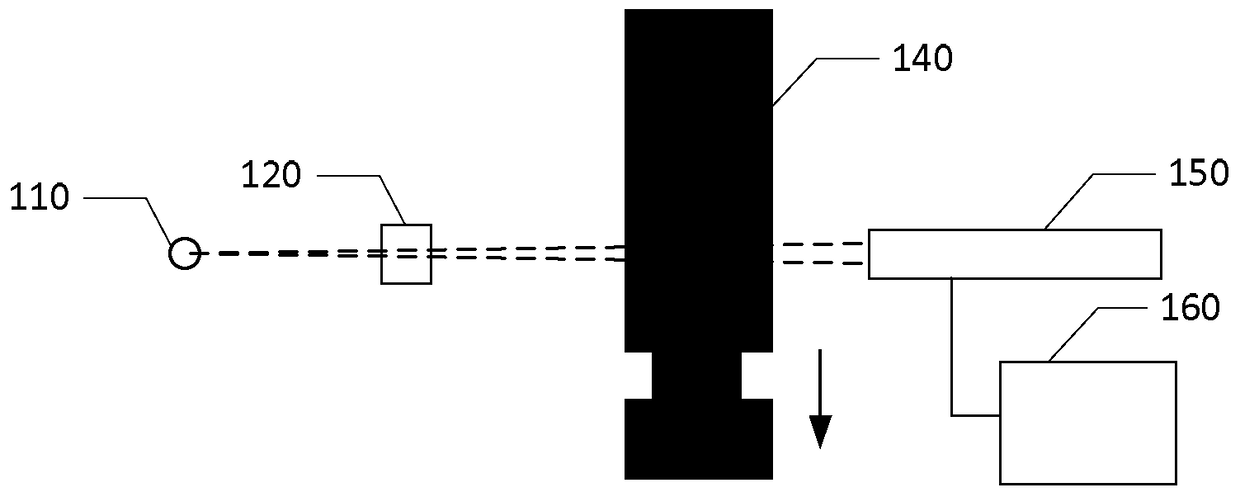

Inspection method and inspection system

ActiveCN105784732ASafe and fast supervisionReduce human judgmentMaterial analysis by transmitting radiationTransmission imageRegion of interest

An inspection method and system are disclosed. The method comprises the steps: obtaining a transmission image of inspected cargos; treating the transmission image, to obtain an interest region; and examining the interest region by using a waste detection model, to determine whether the interest region of the transmission image contains waste cargos. By the inspection method and system, human discrimination can be alleviated in a certain extent, the unpacking detecting rate is reduced, and import and export of wastes is facilitated to be safely and fast supervised.

Owner:NUCTECH CO LTD

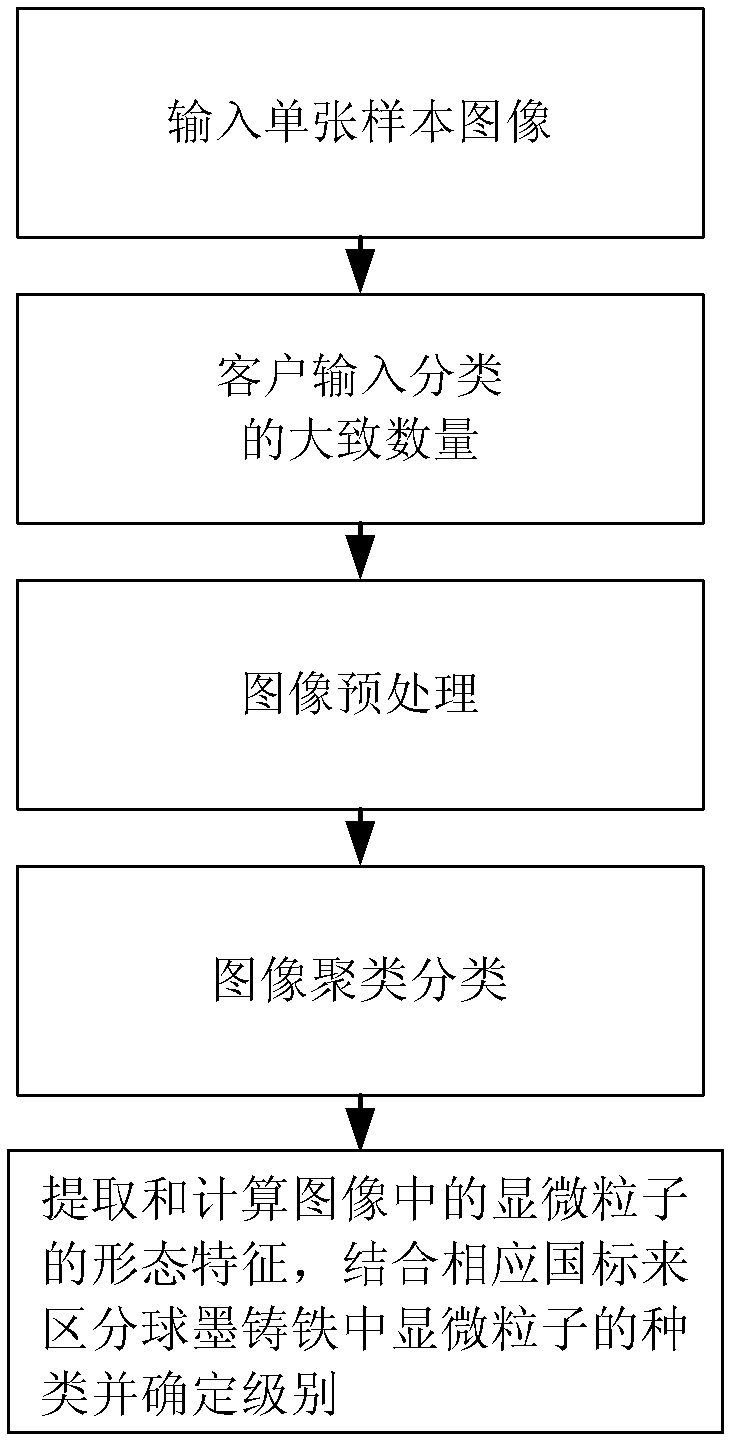

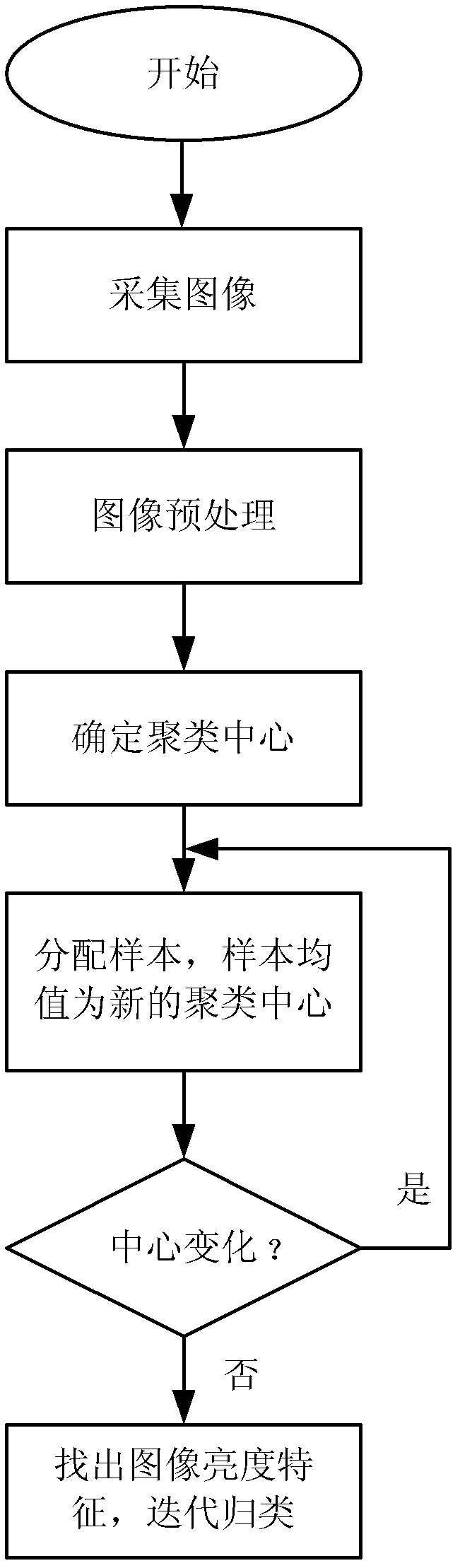

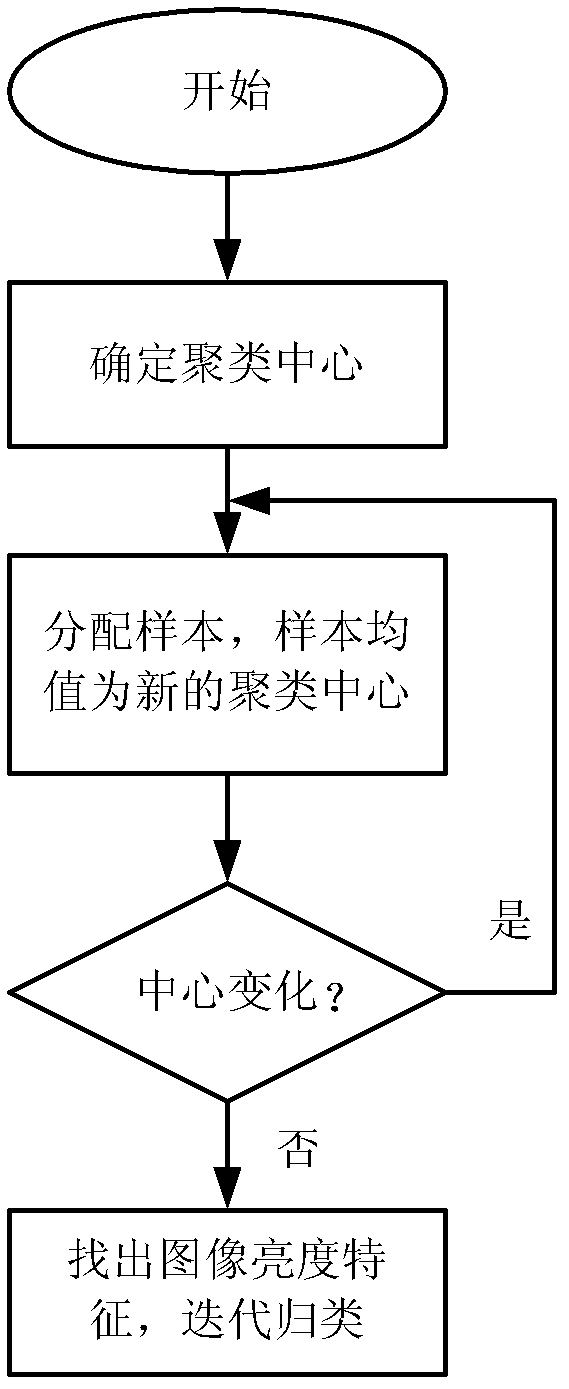

Automatic category rating method for microscopic particles in nodular cast iron

InactiveCN102494987AHigh precisionGood image edgesImage enhancementIndividual particle analysisMicroscopic imageCluster algorithm

The invention discloses an automatic category rating method for microscopic particles in nodular cast iron, which relates to metallographic microscopic image data processing and includes the steps: acquiring images; inputting the estimation value of the category number of the categorical microscopic particles by a client; preprocessing the images; clustering and categorizing the images; and extracting and computing morphological characteristics of the microscopic particles in the images, and distinguishing and rating categories of the microscopic particles in the nodular cast iron according to corresponding national standards. By integrally applying improved K-means clustering algorithm and image partitioning algorithm and by combining metallographic characteristic values, the images are partitioned into the corresponding number of sample images according the categories of the microscopic particles in the images, each partitioned image only contains one category of microscopic particles, and a user can select proper microscopic particles for category rating as needed, so that the automatic category rating method overcomes the shortcoming that processing for metallographic images by means of existing metallographic microscopic analysis technology, particularly processing for the metallographic images containing various textures lacks accuracy and authority of inspection.

Owner:天津卓朗科技发展有限公司

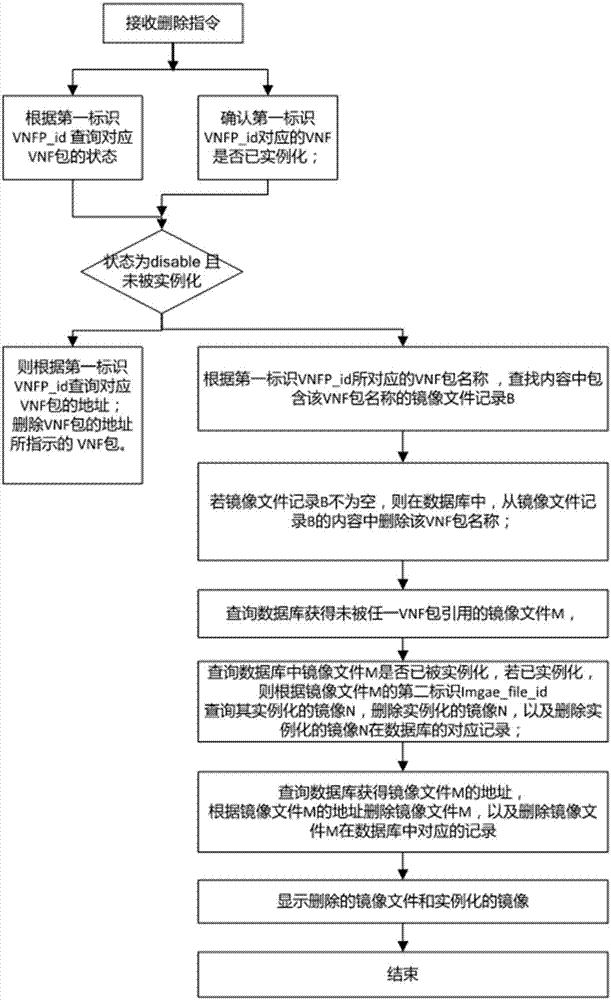

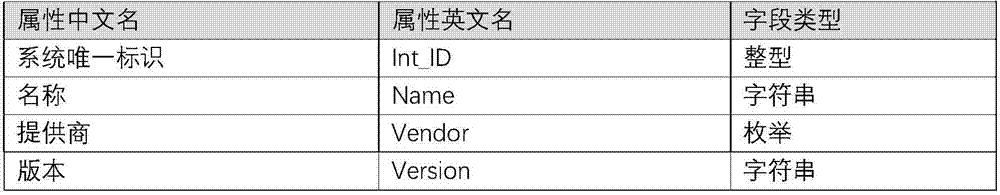

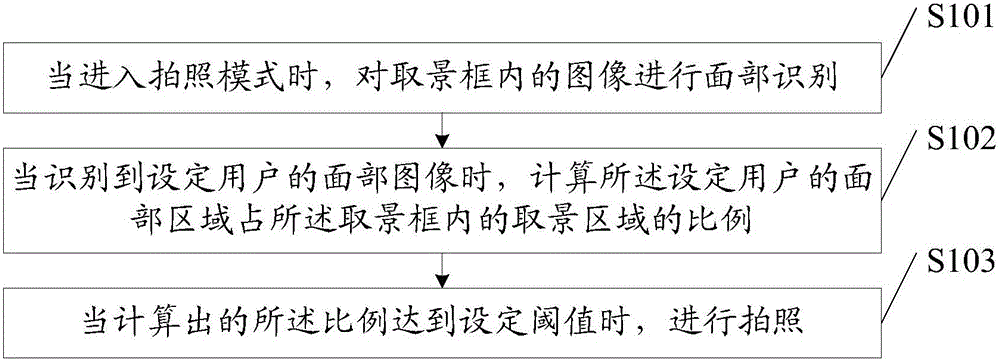

VNF (Virtualised Network Function) package and deleting method and device for mirror image file referred thereby

ActiveCN107357836AEasy to operate manuallyImprove processing efficiencySpecial data processing applicationsComputer visionMirror image

The invention provides a VNF (Virtualised Network Function) package and a deleting method and device for a mirror image file referred thereby, and aims at solving the problem that the relation among the VNF package, the mirror image file, and a mirror image instance generated by the mirror image file is complex and the mirror image file and the like are easily mistakenly deleted and leaked while deleting the VNF package in the prior art. The method comprises the following steps: S101, searching a mirror image file record B including the name of the VNF package according to the VNF package name corresponding to a first identifier VNFP_id; S102, if the mirror image file record B is not empty, deleting the VNF package name from the content of the mirror image file record B in a database; and S103, searching the database to obtain the mirror image file M without being interfered by any VNF package, and searching the database to determine whether the mirror image file M is instantiated; if so, searching an instantiated mirror image N according to a second identifier Image_file-id of the mirror image file M; and deleting the instantiated mirror image N. With the adoption of the method and the device, the defect of avoiding mistaken deleting and leaking can be achieved.

Owner:INSPUR TIANYUAN COMM INFORMATION SYST CO LTD

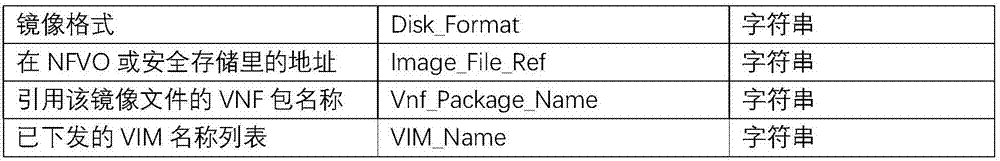

Method for guaranteeing upper-case asset code input into FRU (field replace unit)

InactiveCN105511921AGuarantee the quality of shipmentsReduce human judgmentSoftware engineeringProgram loading/initiatingProgramming languageField replaceable unit

The invention discloses a method for guaranteeing an upper-case asset code input into an FRU (field replace unit), belongs to the field of FRU refreshing after upgrading of BIOS (basic input output system) and aims to solve the technical problem that input fails when the brushed-in asset code is lower-case. According to the method, the asset code is brushed into a DMI (direct media interface) and the FRU in an asset code write-in mode through a scanning spear, and the method comprises the following control steps: (1) a DOS (disk operating system) is accessed after USB flash disk startup; (2) the asset code is written into the DMI and the FRU by the scanning spear; (3) the written-in asset code is subjected to automatic script check; (4) brushing in succeeds if the written-in asset code checked in the step (3) is upper-case; (5) the step (2) is repeated on the asset code if the written-in asset code checked in the step (3) is lower-case.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

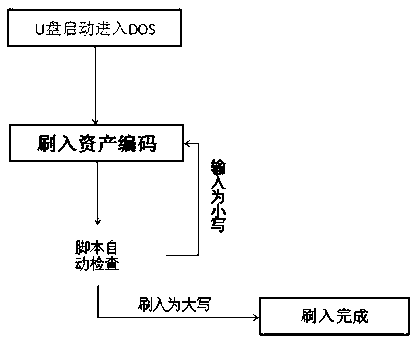

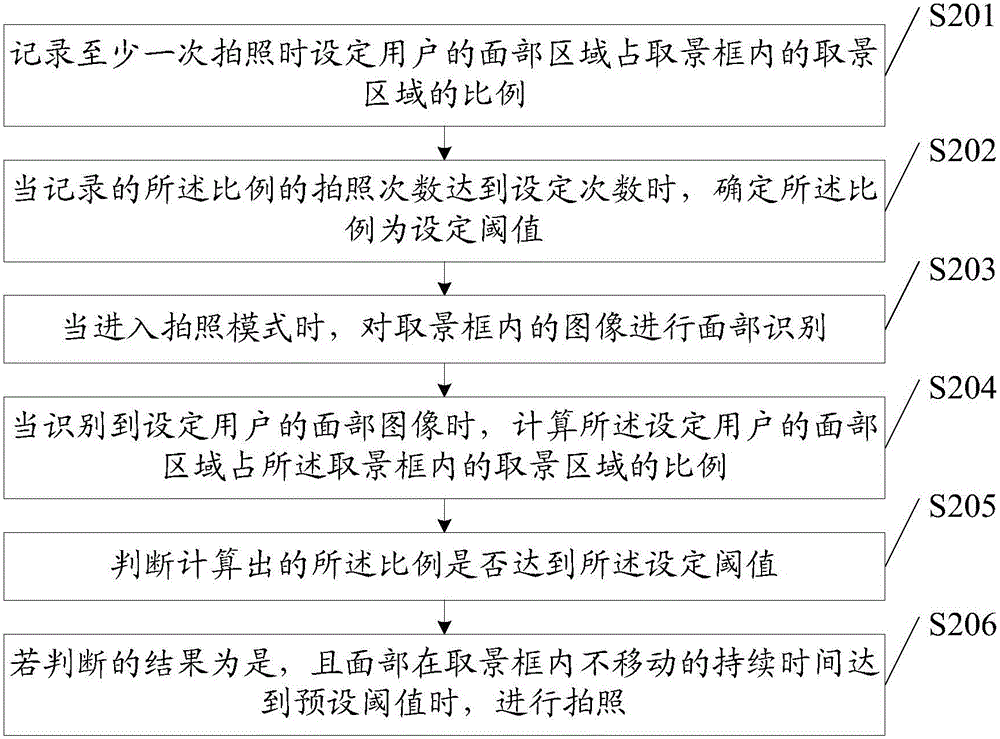

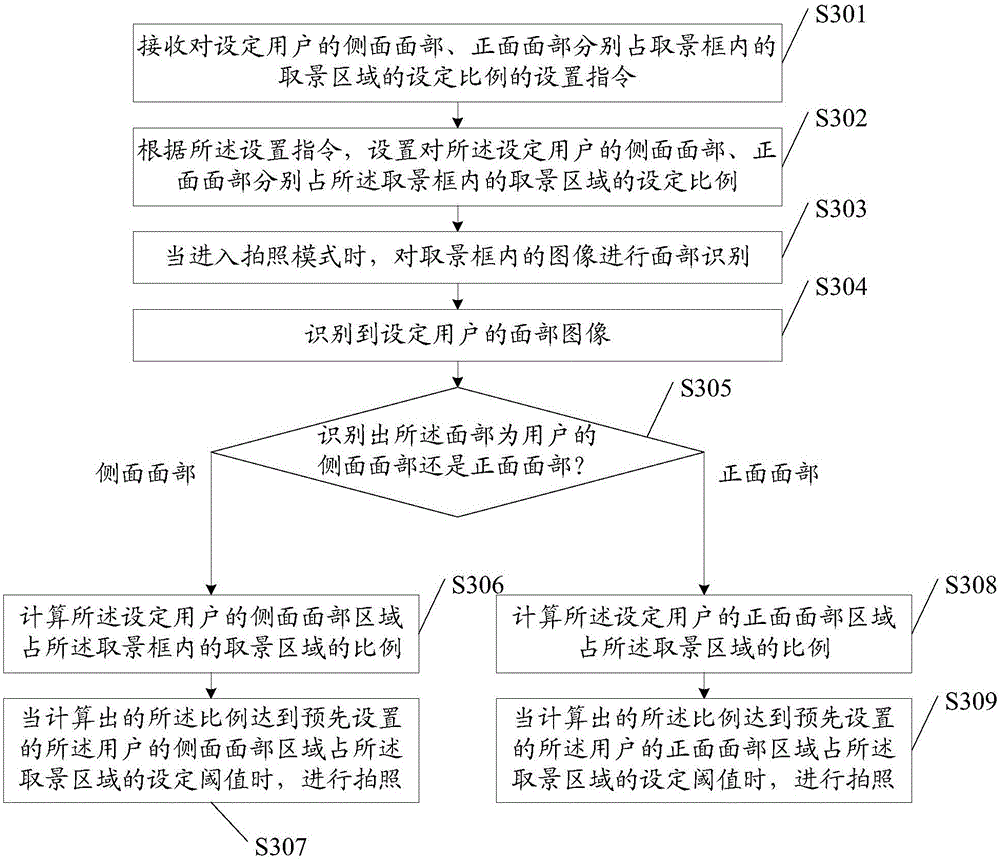

Photographing method and terminal

InactiveCN104994300AReduce stepsReduce human judgmentTelevision system detailsColor television detailsComputer graphics (images)Computer vision

Owner:MEIZU TECH CO LTD

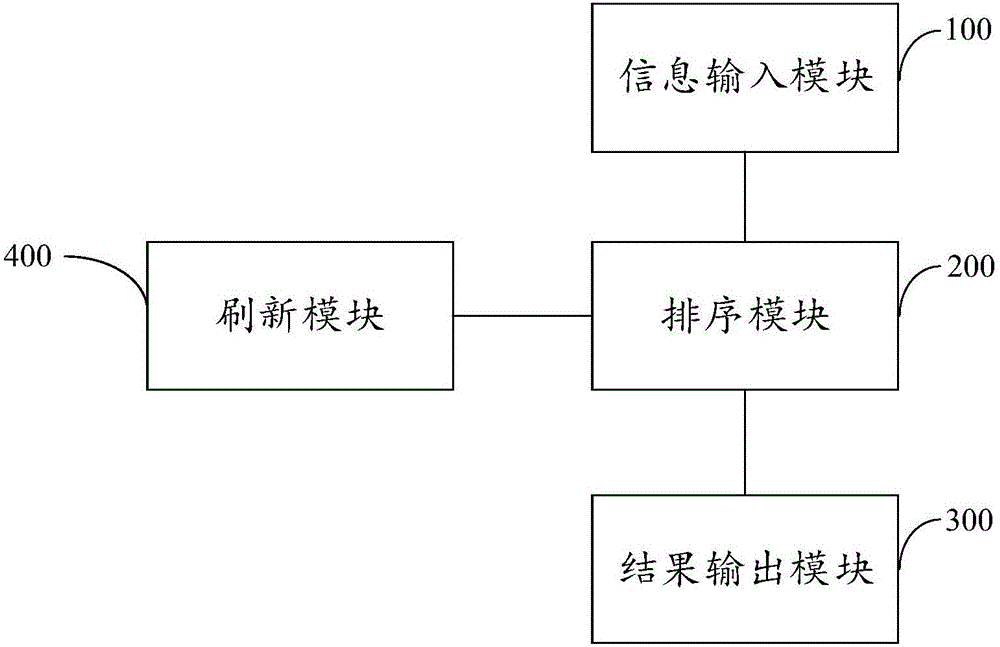

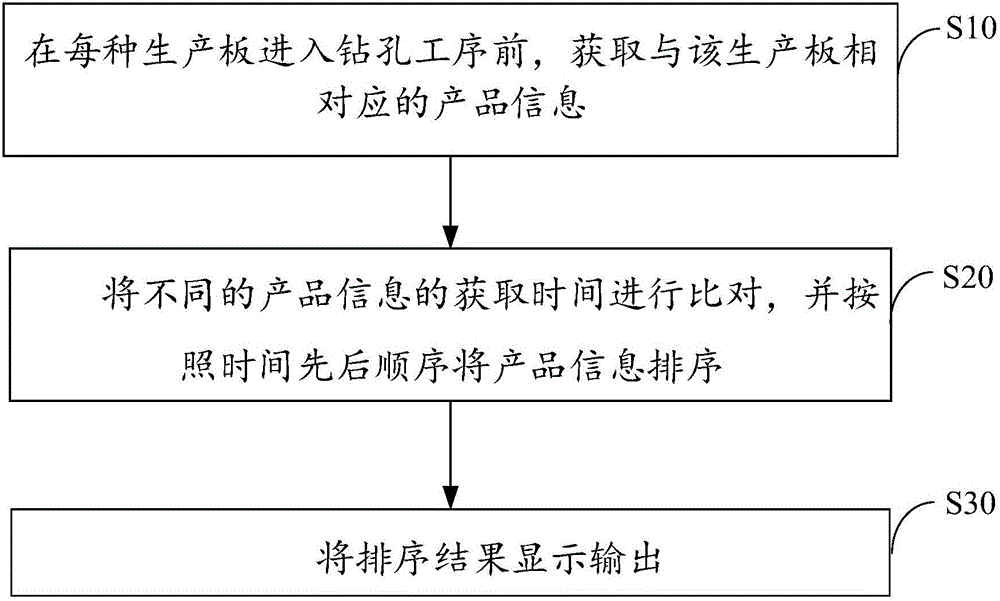

PCB plug hole aluminum sheet making automatic scheduling system and method

ActiveCN106535483AProduction scheduling simplifiedImprove the effective output ratePrinted circuit manufactureMachining timeComputer engineering

The present invention discloses a PCB plug hole aluminum sheet making automatic scheduling system and method. The system comprises an information input module and a sorting module; the information input module is configured to obtain the product information corresponding to a production board before each production board enters a drilling process; and the sorting module is configured to obtain the time of different product information for comparison and sort the product information according to the sequential order of the obtained time, and the sorting result is the first aluminum sheet making sequence. The PCB plug hole aluminum sheet making automatic scheduling system and method obtain the product information before each production board enters the drilling to determine the processing time of the production board drilling, and perform sorting of the drilling of each production board to take as the sequential order of making scheduling and realize the synchronization correlation of the production board drilling sequence and the aluminum sheet making sequence so as to simplify the aluminum sheet making scheduling, effectively improve the effective yield rate of the plug hole processing procedure and improve the work efficiency.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

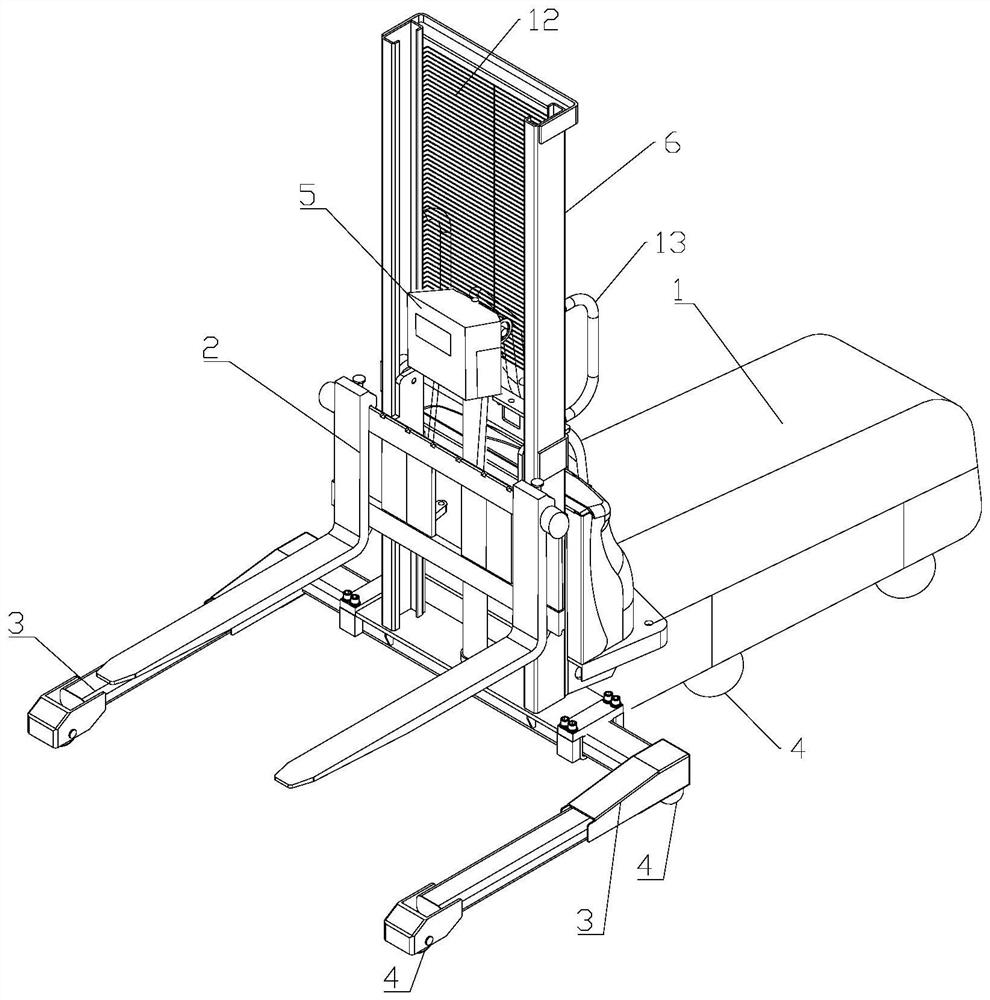

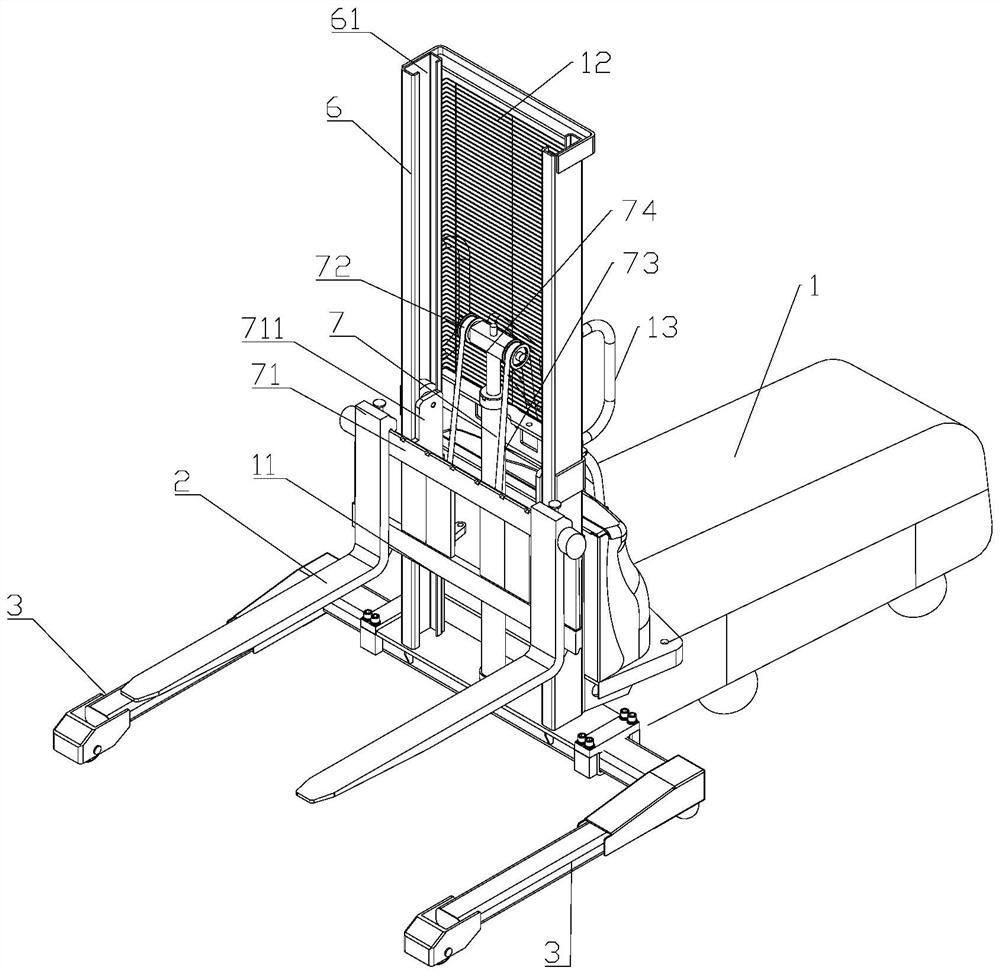

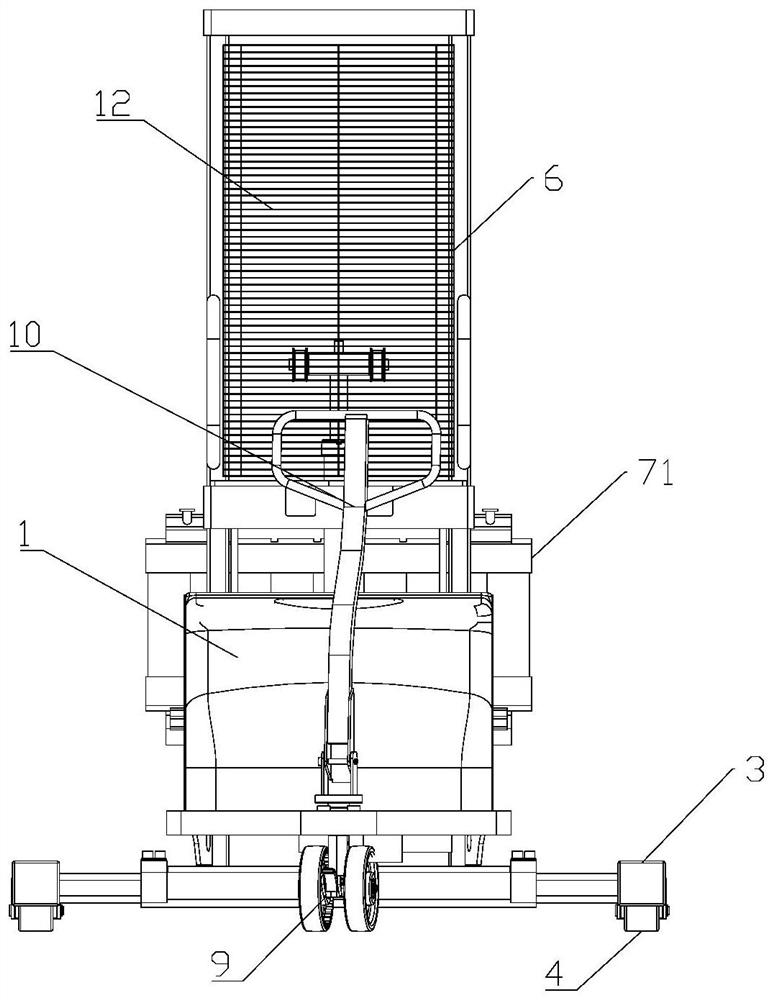

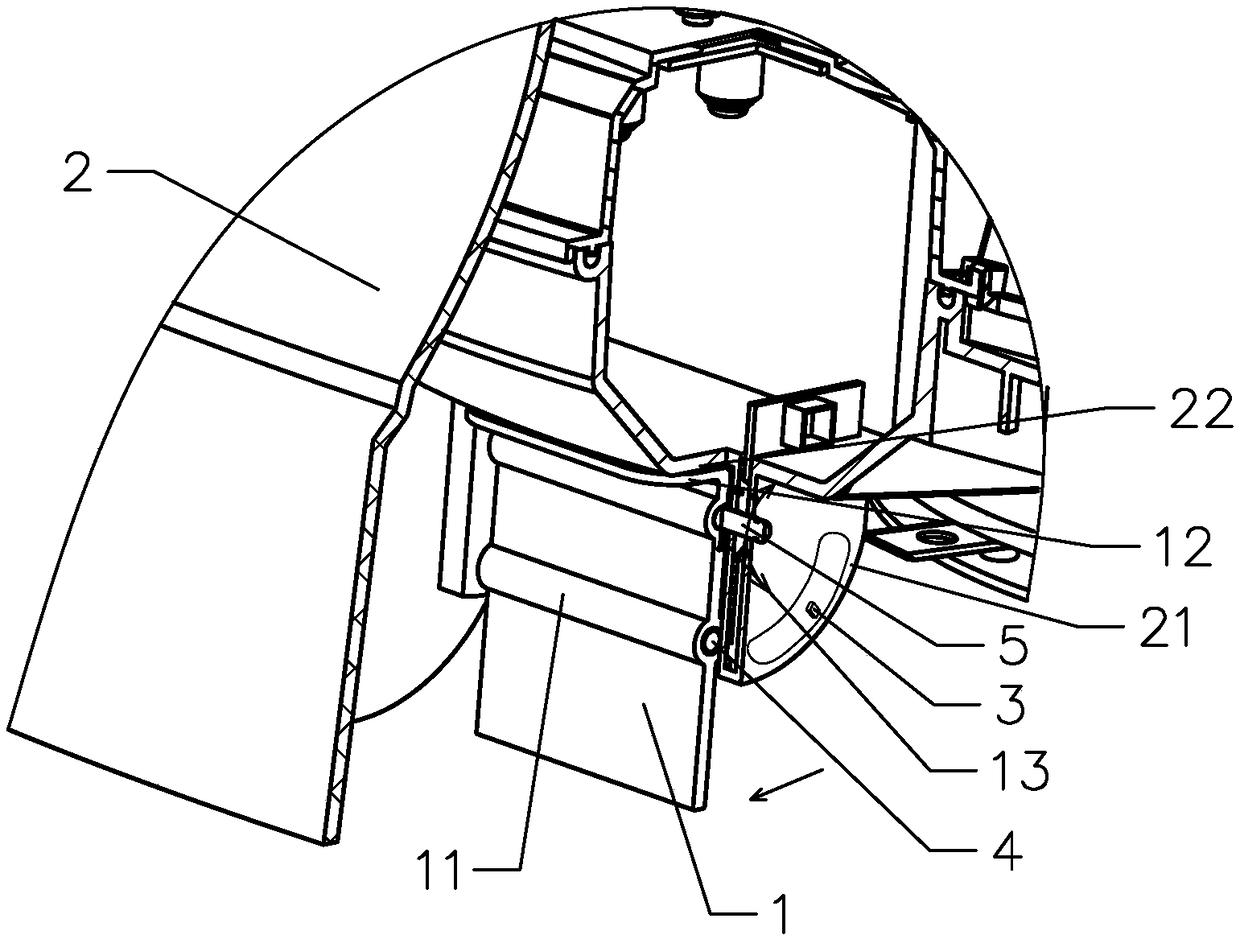

Forklift robot with pattern recognition device

PendingCN111807269AEasy to moveAvoid toppling back and forthLifting devicesLogistics managementControl engineering

The invention discloses a forklift robot with a pattern recognition device and belongs to the technical field of logistics equipment. The forklift robot comprises a vehicle body, a pallet fork, a lifting assembly and a pattern recognition assembly; the front end of the vehicle body is fixedly provided with a vertically arranged portal, and two horizontally arranged support legs are detachably fixed to the bottom of the portal; the pattern recognition assembly comprises a box body, a pattern acquisition camera, a rotary table, a motor, a storage battery pack and a controller; the lifting assembly comprises a lifting cylinder, a chain wheel, a chain and a lifting plate, the top of the rear end of the pallet fork is hinged to the lifting plate, the outer end of the lifting plate is provided with a sliding block in sliding fit with a sliding groove, the lifting cylinder is vertically arranged at the front end of the vehicle body, a telescopic shaft of the lifting cylinder is fixedly arranged with the chain wheel through a support, and the telescopic shaft of the lifting cylinder drives the chain wheel to lift up and down, so that the lifting plate drives the pallet fork and the box body to lift up and down. The forklift robot with the pattern recognition device has the advantages of being foldable, moving stably and and having the up-down lifting pattern recognition function.

Owner:京良(广州)科技股份有限公司

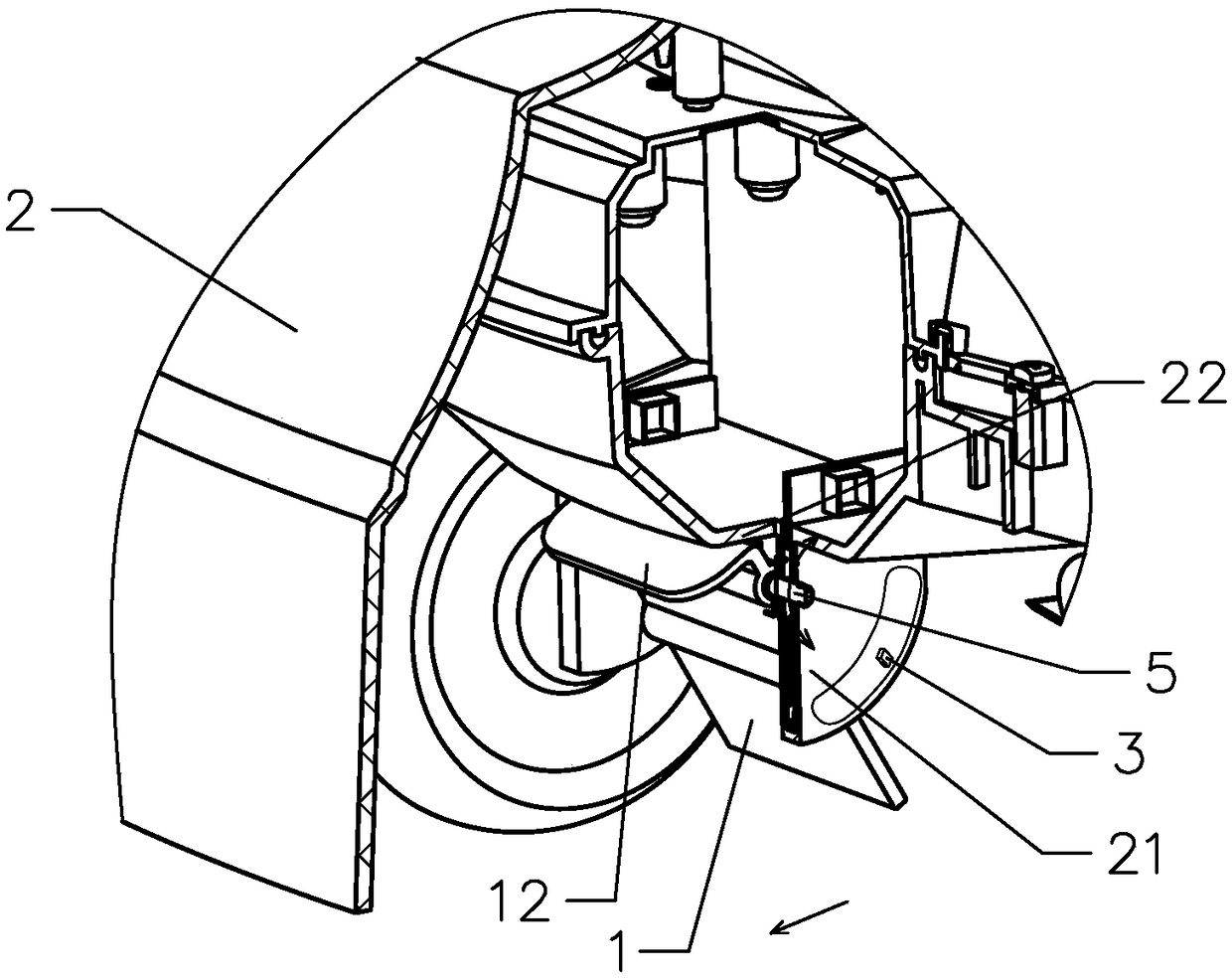

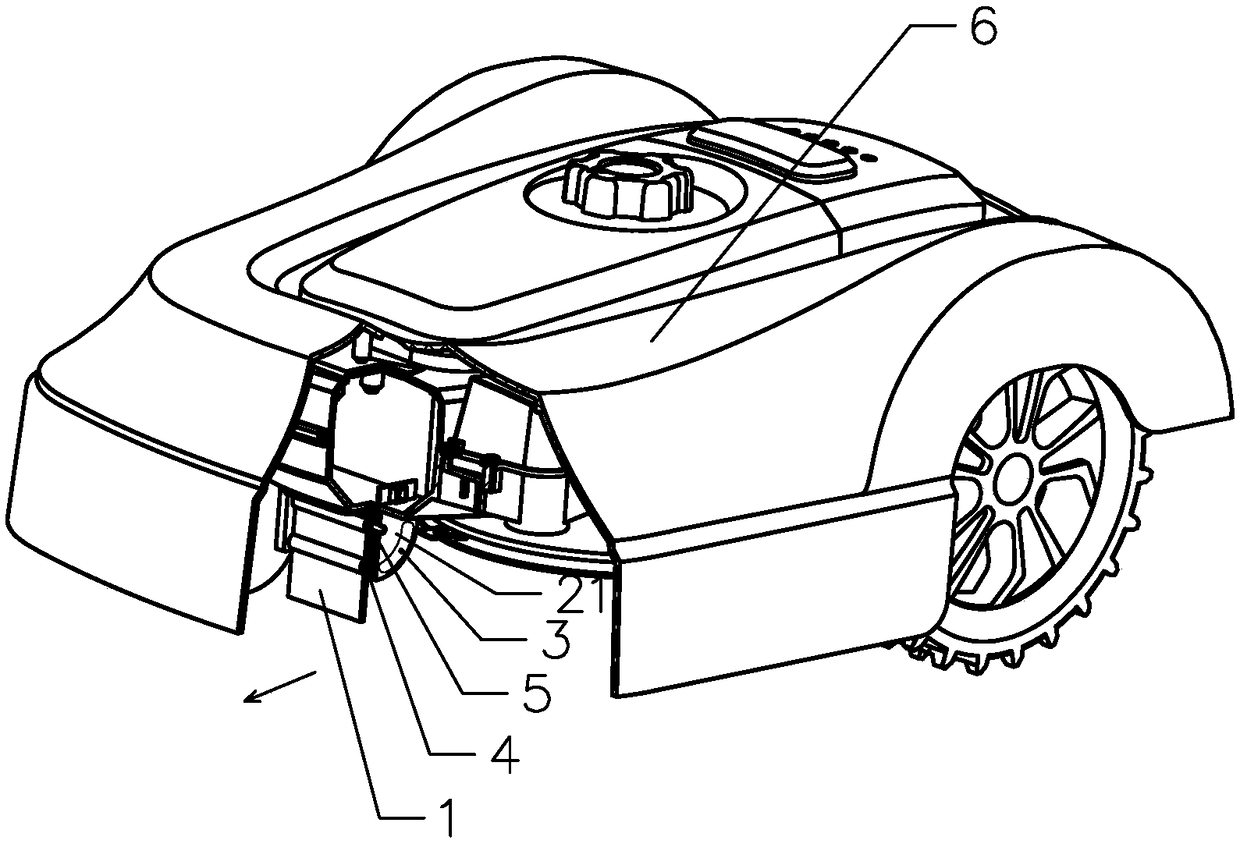

Grass height detection device and mower

PendingCN108738636AReduce workloadHigh degree of automationMowersUsing electrical meansAngular degreesEngineering

The invention provides a grass height detection device and a mower. The grass height detection device is mounted on a moving part and includes a shift plate and a height measuring mechanism; the upperend of the shift plate is rotationally connected with the moving part through a rotary shaft; the lower end of the shift plate is above a ground; the axis of the rotary shaft is perpendicular to a moving direction of the moving part such that when the moving part is in motion, the shift plate is driven by grass to rotate; the height measuring mechanism helps detect real-time rotational angle of the shift plate; the greater the rotational angle of the shift plate, the taller the grass, and on the contrary, the smaller the rotational angle of the shift plate, the more dwarf the grass; grass height can be judged according to angle changes, the grass is quantified to great extent, fewer manual judgments are required, and obtained results are accurate; since manually judging grass height by eyes is not required, automation level is high, workload is reduced for workers, and working efficiency is improved; a work strategy can be adjusted according to grass height, the work strategy with lowlabor intensity can be achieved, and energy consumption is reduced.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

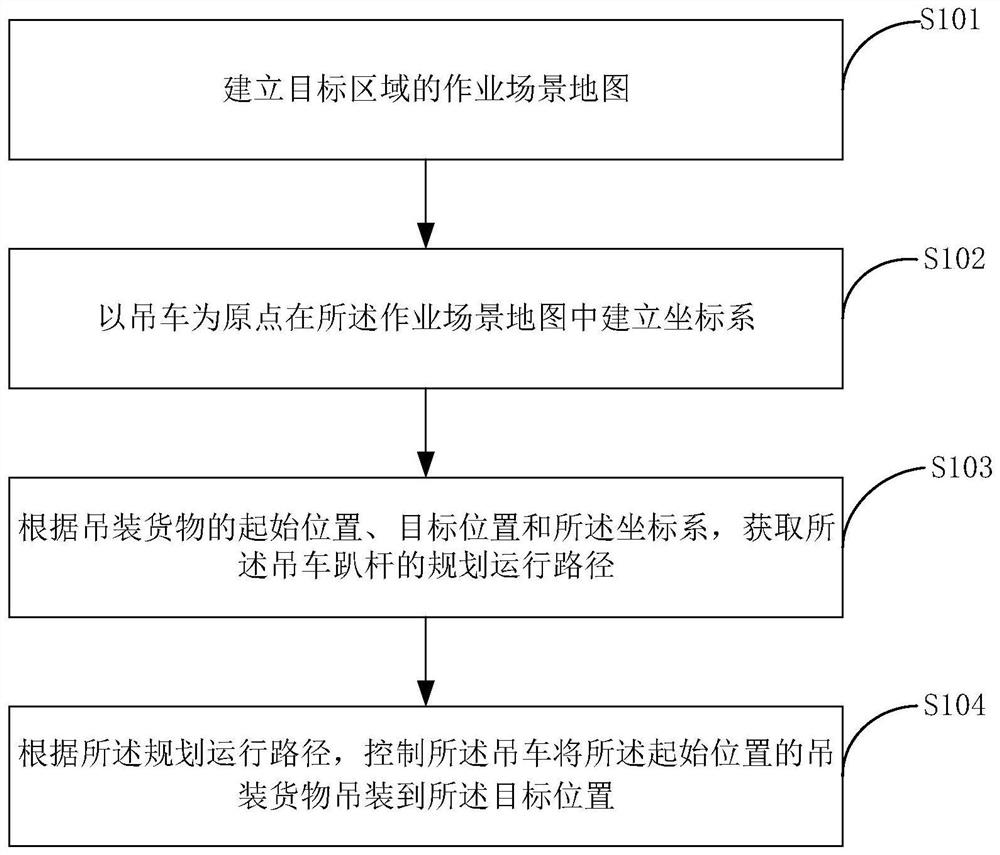

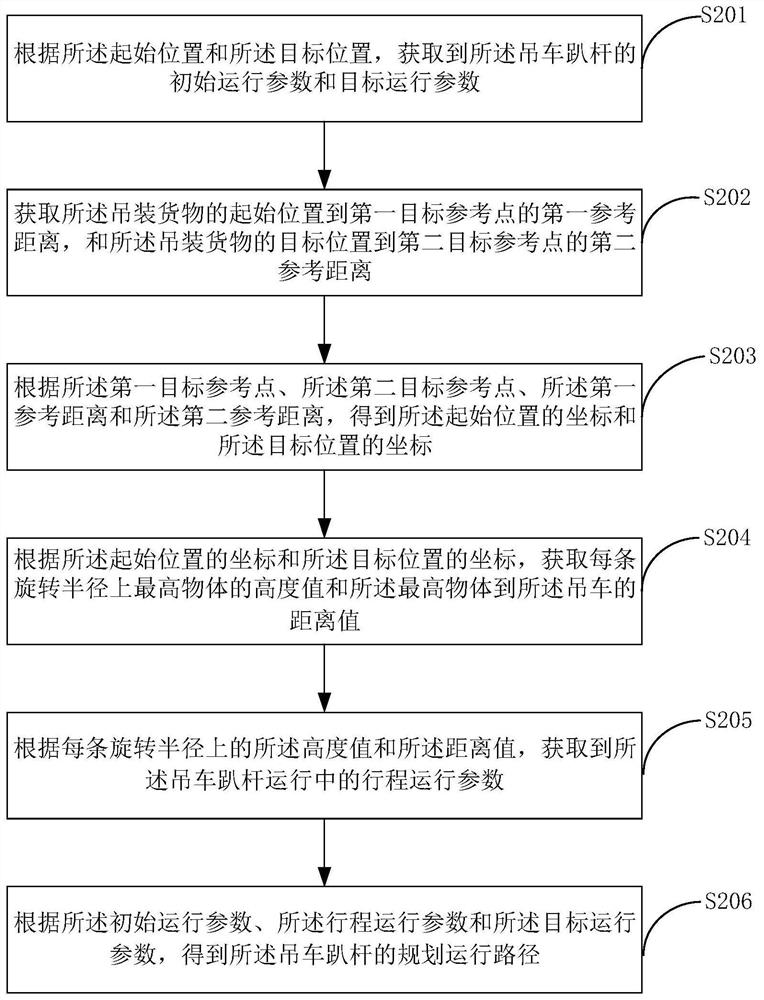

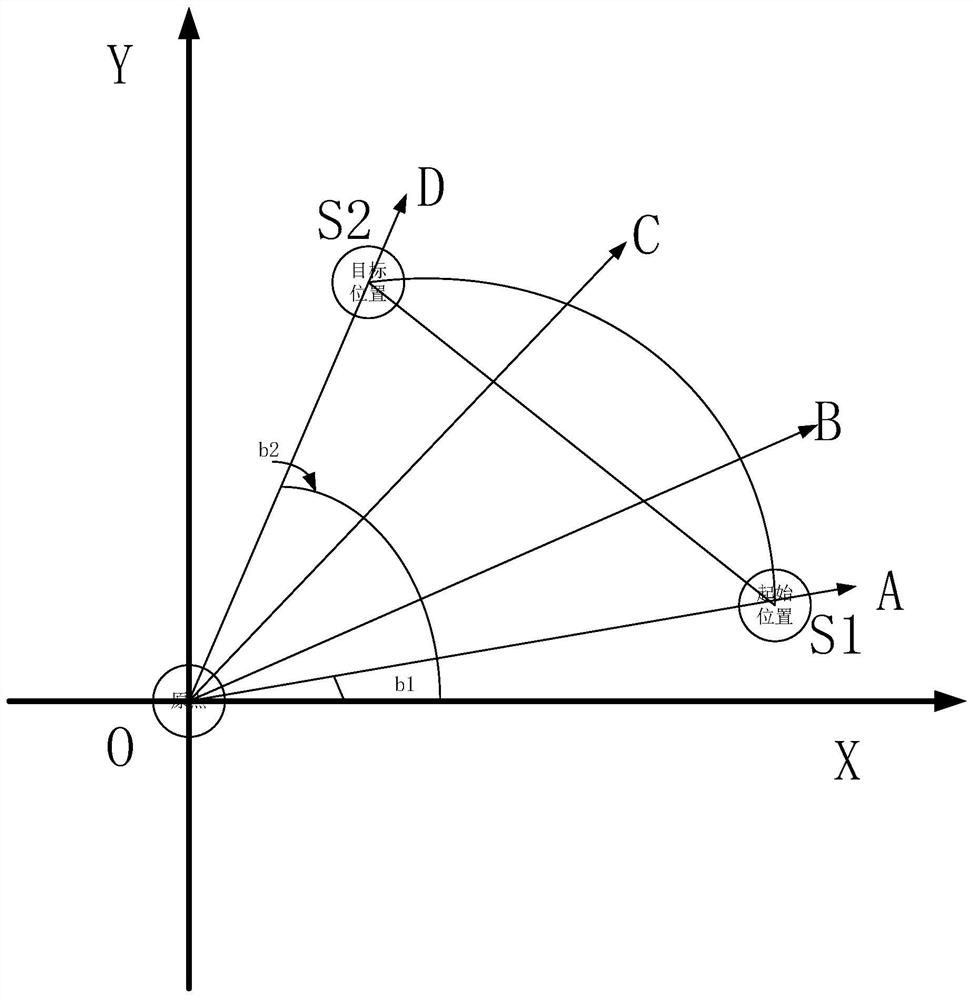

Crane collision avoidance control method, device and system, computer equipment and storage medium

The invention provides a crane collision avoidance control method, device and system, computer equipment and a storage medium. The method comprises the steps of establishing an operation scene map ofa target area; establishing a coordinate system in the operation scene map by taking a crane as an original point; according to the starting position and the target position of hoisted goods and the coordinate system, obtaining a planned running path of a crane lying rod; and controlling the crane to hoist the hoisted goods at the initial position to the target position according to the planned running path. According to the crane collision avoidance control method, the problem that the crane operating on an ocean platform does not perform collision avoidance monitoring and easily causes collision accidents in the prior art is solved, the guarantee is provided for the safe operation of the crane on the ocean platform, the occurrence of the collision accidents is avoided, and the personneland property loss is reduced.

Owner:湖北微特智能技术有限公司

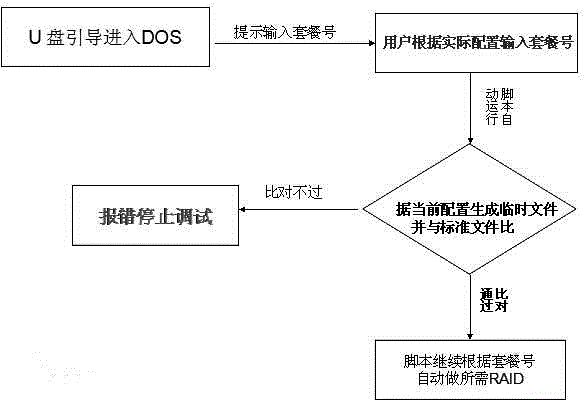

Method for automatically verifying hard disk configuration of server

InactiveCN104898987AAchieve the purpose of automationReduce human judgmentInput/output to record carriersRAIDTechnical standard

The present invention, relating to the server technology for various hard disk customization requirements, provides a method for automatically verifying hard disk configuration of a server. According to the present invention, standard files are generated for a plurality of configurations by a command issued by a DOS; then a temporarily generated file is compared with the selected standard file; if a comparison result indicates that the files are consistent, the corresponding configuration passes verification; and if the comparison result indicates that the temporarily generated file is different from the selected standard file, an error is reported. If the configuration has demands on the RAID, RAIDs can also be automatically created in batches according to the configuration, thereby achieving the objective of automation and improving the working efficiency.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

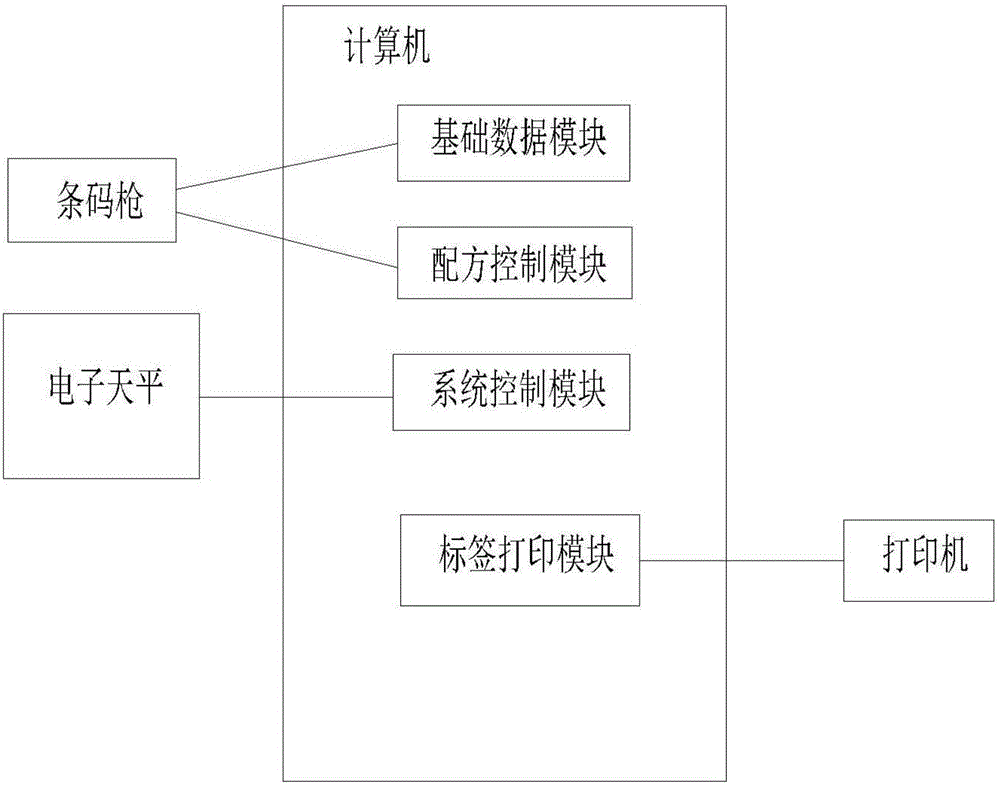

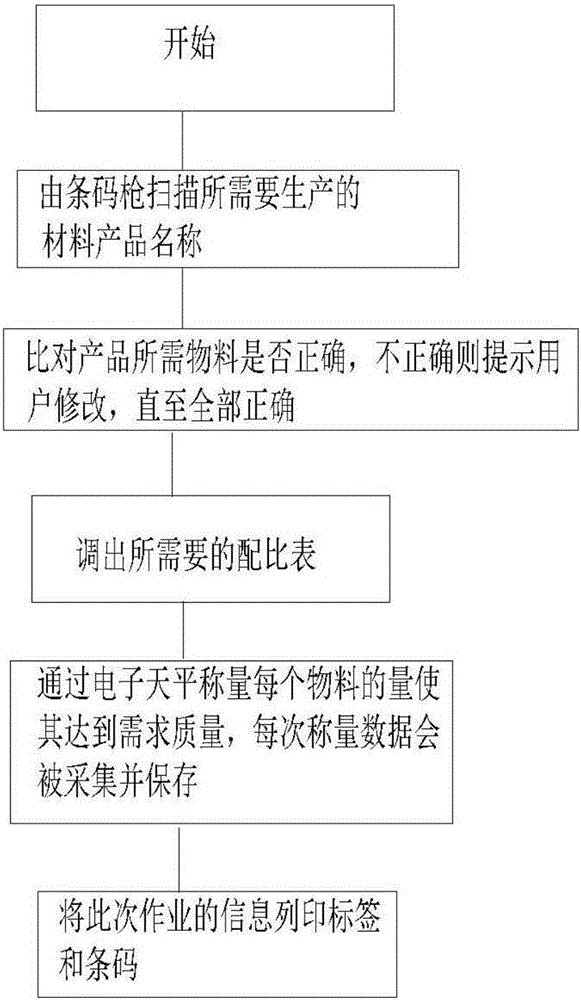

LED glue preparation control system and method

InactiveCN105760906AEasy to operateReduce human judgmentCo-operative working arrangementsSpecial purpose weighing apparatusBarcodeCalculator

The invention discloses an LED glue preparation control system, which can solve the problem of raw material loss caused by manual errors, calculation errors and hand errors, completely enable an operator to throw away a calculator, enable the operation to be simple, and reduce manual judgment steps. The system comprises a computer, an electronic balance and a barcode gun, wherein the computer is internally provided with a basic data module, a formula control module and a system control module; the basic data module provides basic information such as a product model, a wafer model, a waveband type and a class; the barcode of each material is acquired through scanning by the barcode gun; the system control module compares the barcode of each material with a material barcode already existing in a formula table; the formula control module provides demand mass of each material in the formula table; the amount of each material is weighed by the electronic balance to achieve the demand mass. The invention also provides a control method.

Owner:SHINEON BEIJING TECH

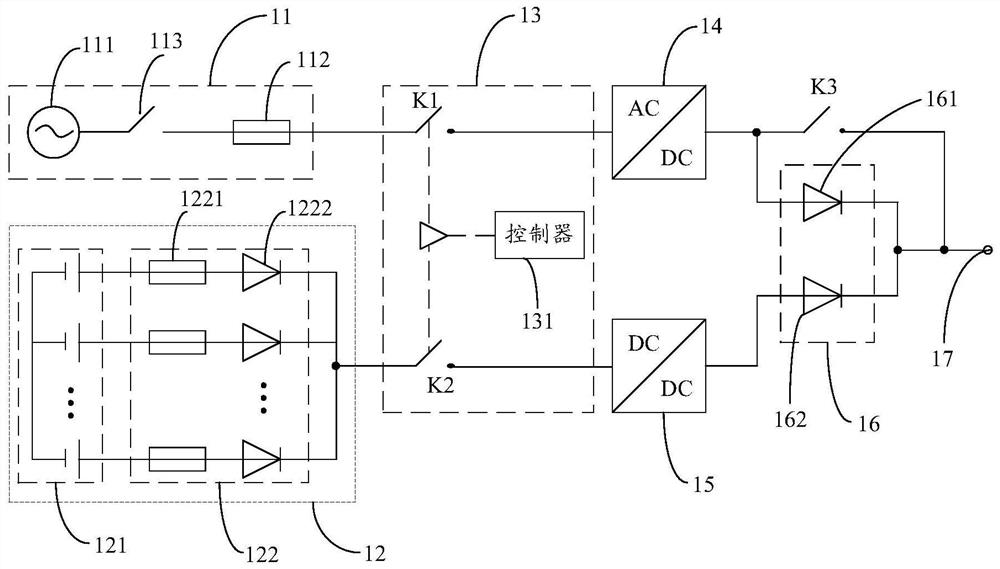

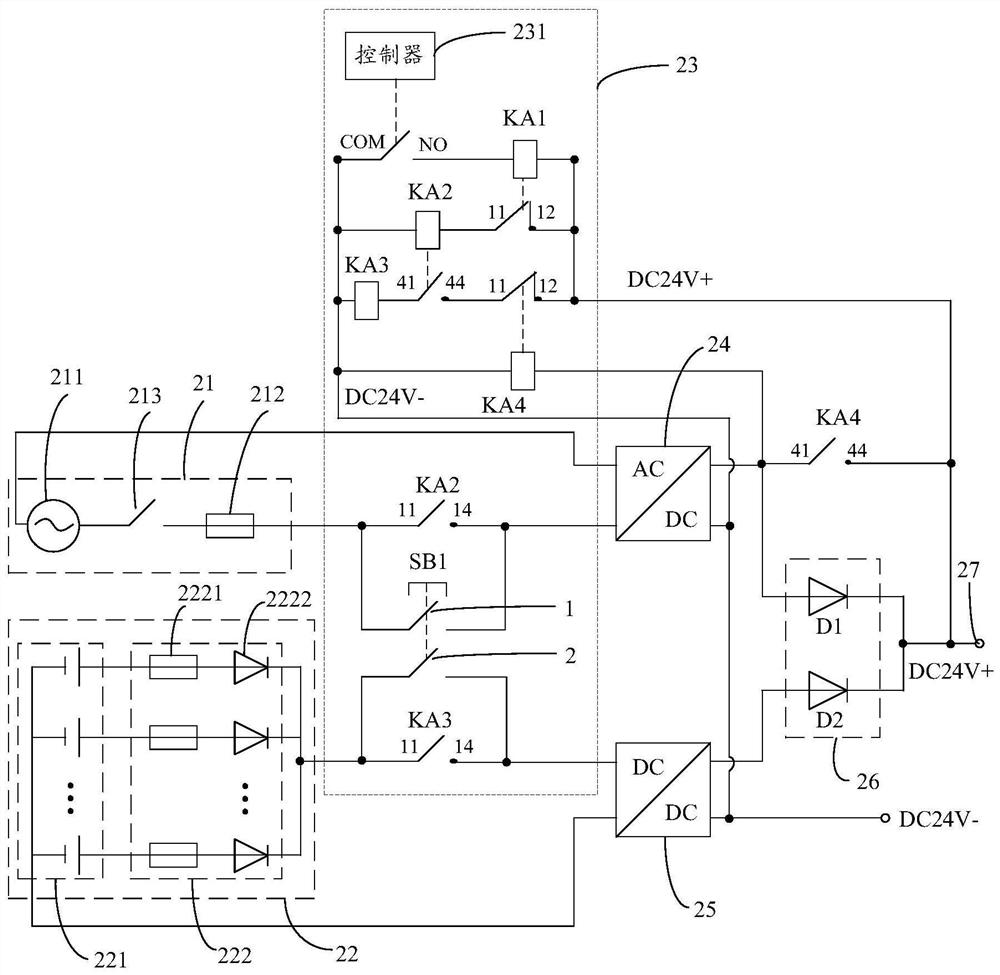

Black-start circuit structure of low-voltage energy storage system and control method

InactiveCN112186878ALarge capacityImprove cycle lifeBatteries circuit arrangementsAc network load balancingElectrical batteryHemt circuits

The invention relates to the technical field of power electronics, and particularly discloses a black-start circuit structure of a low-voltage energy storage system and a control method. The black-start circuit structure comprises a mains supply module, an energy storage battery module, a control module, an alternating current-direct current conversion module, a direct current-direct current conversion module, an isolation module and an output module connected with a load, wherein the input end of the control module is connected with the mains supply module and the energy storage battery module, the output end of the control module is connected with the alternating current-direct current conversion module and the direct current-direct current conversion module, the input end of the isolation module is connected with the alternating current-direct current conversion module and the direct current-direct current conversion module, and the output end of the isolation module is connected with the output module. By means of the mode, electricity can be directly taken from the energy storage battery module to serve as a black-start power source, a UPS does not need to be used, the black-start time is prolonged, the maintenance cost is reduced, and the installation space is saved.

Owner:厦门量道储能信息技术有限公司

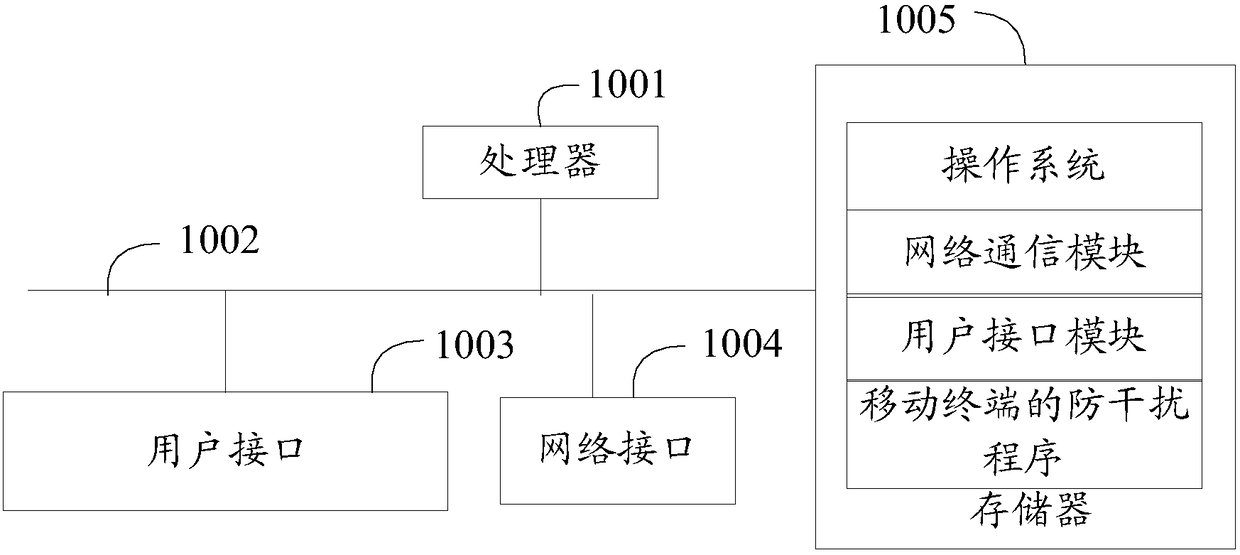

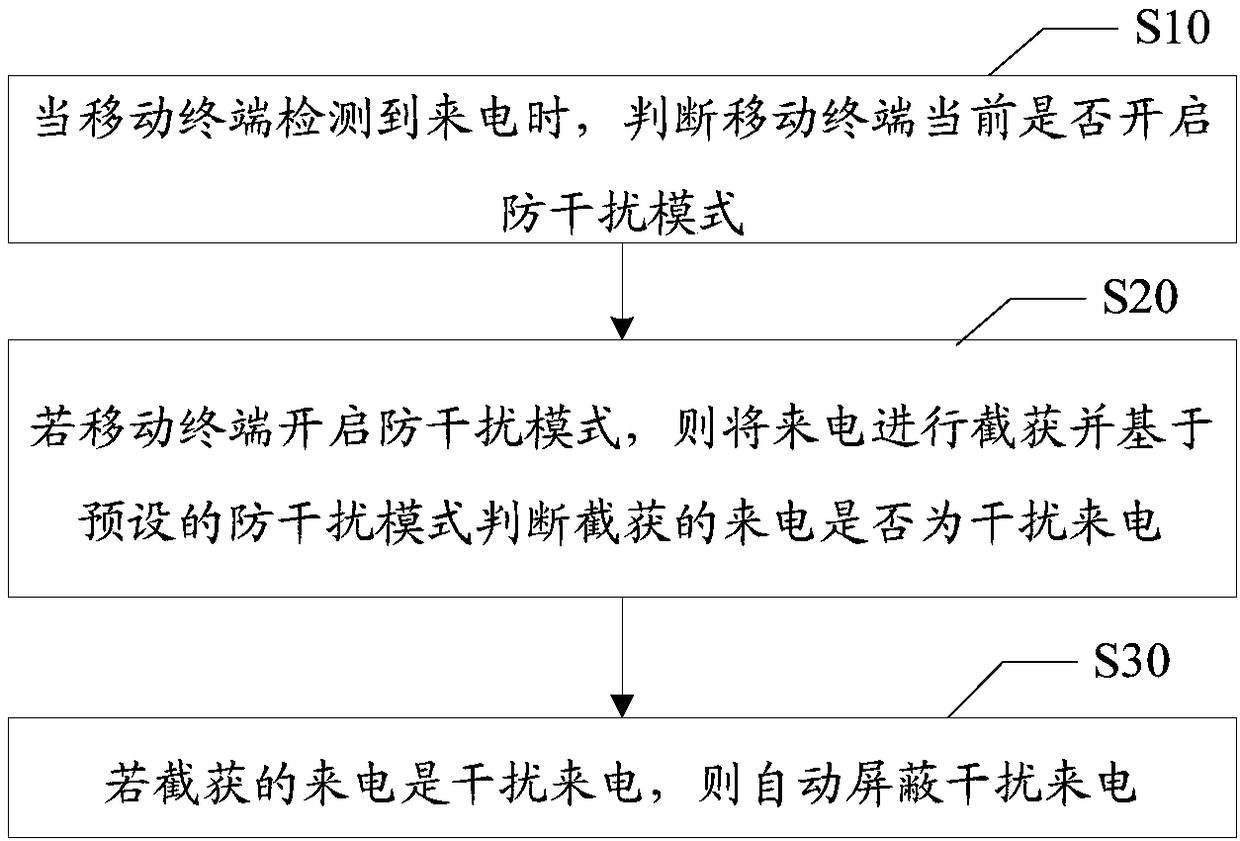

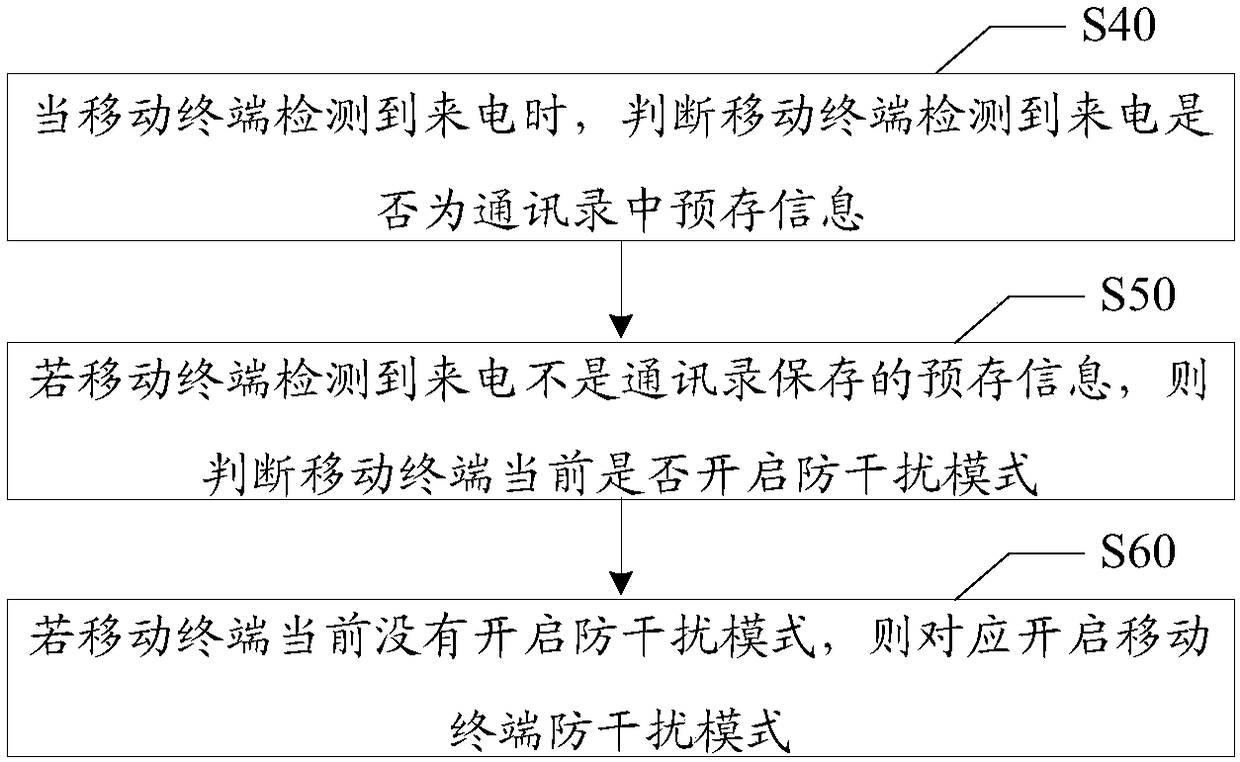

Anti-interference method, device and readable storage medium for mobile terminal

InactiveCN109257479ASmart anti-jamming modeReduce human judgmentSubstation equipmentTelecommunicationsDevice Sensor

Owner:ZTE CORP

Intelligent emergency material support decision-making system based on artificial intelligence

InactiveCN109508887AShort processing timeIncrease costResourcesLogisticsArtificial general intelligenceThe Internet

The invention discloses an intelligent emergency material support decision-making system based on artificial intelligence, which comprises an Internet commercial map and a background server, and further comprises the following modules: a detection module, wherein a reconnaissance personnel captures image information on the spot by using a photographing device, and transmits the image information to the background server in real time; An identification module transfers image information from the background server, analyzes the image information through computer vision technology, identifies information of damaged equipment or damaged materials, and generates damaged information and sends the damaged information to a material screening module. The material screening module screens the emergency materials according to the damage information sent by the identification module, determines the type and quantity of the emergency materials, and generates a demand list of the emergency materials.

Owner:PANZHIHUA POWER SUPPLY COMPANY STATE GRID SICHUAN ELECTRIC POWER

Wavelet analysis-based grinding machining working condition detection system and method thereof

ActiveCN101819119BAvoid damageQuickly and automatically judge the processing statusSubsonic/sonic/ultrasonic wave measurementInvestigating machinabilityAcoustic emissionWavelet transform analysis

Owner:NANJING UNIV +1

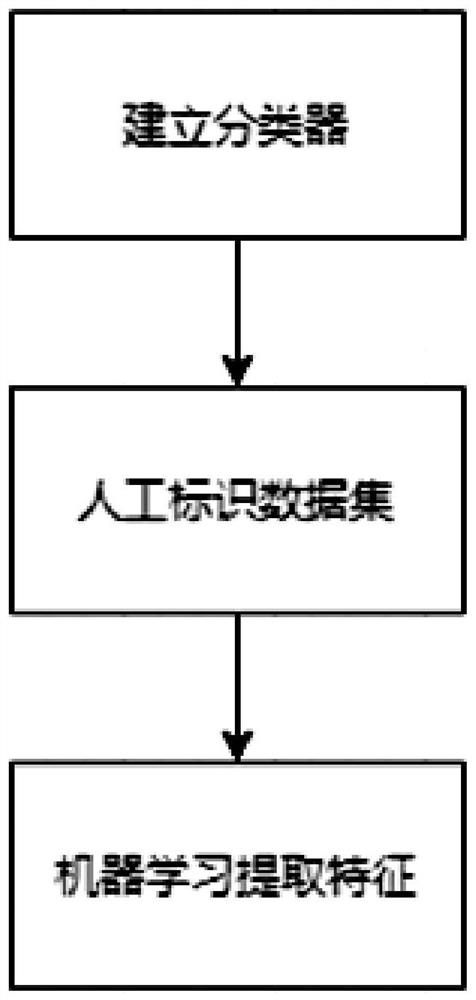

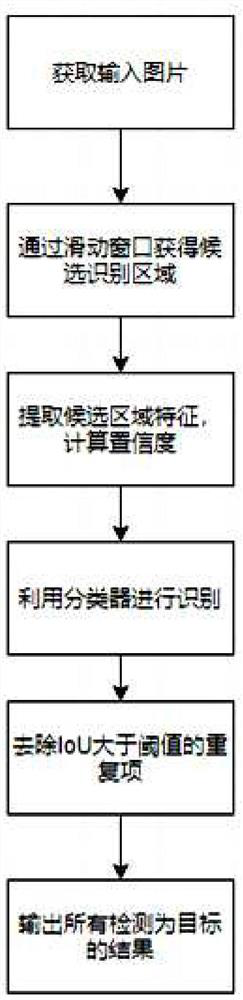

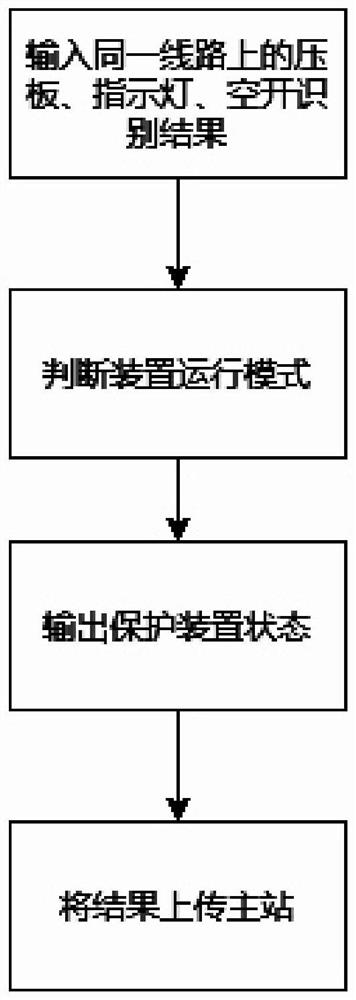

Method for judging and processing operation state of secondary protection equipment of transformer substation

PendingCN114421613AEasy to identify categoriesReduce human judgmentCircuit arrangementsNeural architecturesPrimary stationTransformer

The invention relates to a substation secondary protection equipment operation state judgment and processing method, which comprises the following steps of: establishing classifiers related to an indicator lamp, a pressing plate and an air switch, collecting and marking data samples of the classifiers, and calculating and extracting characteristic values of the classifiers; obtaining a fixed-point picture of the transformer substation protection device, intercepting a candidate recognition region, extracting a feature value of the candidate region through calculation, obtaining the confidence coefficient of the candidate recognition region, removing the region with the low confidence coefficient, and outputting the results of an indicator lamp, a pressing plate and an air switch on the transformer substation protection device. And judging a line operation mode according to the output indicating lamp, pressing plate and air switch results so as to judge whether the pressing plate is normally switched on or off, and outputting the results and uploading the results to a main station. According to the method, the inspection result can be automatically generated after inspection, the abnormal information of the protection device is extracted, the labor intensity of inspection is effectively reduced, the error rate is reduced, and intelligent monitoring of the transformer substation protection device is realized.

Owner:YICHANG POWER SUPPLY CO OF STATE GRID HUBEI ELECTRIC POWER CO LTD

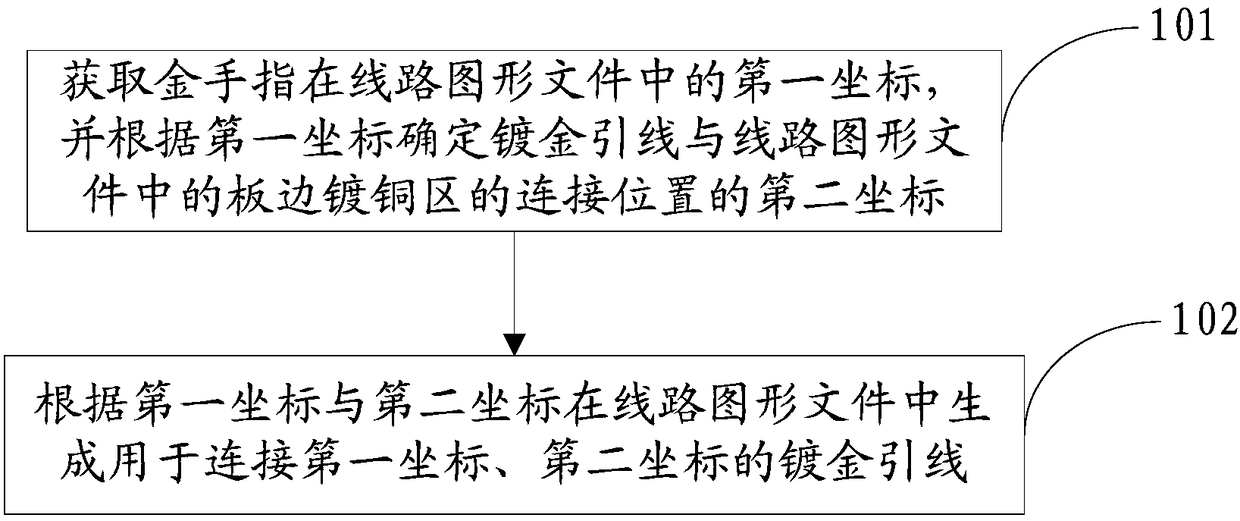

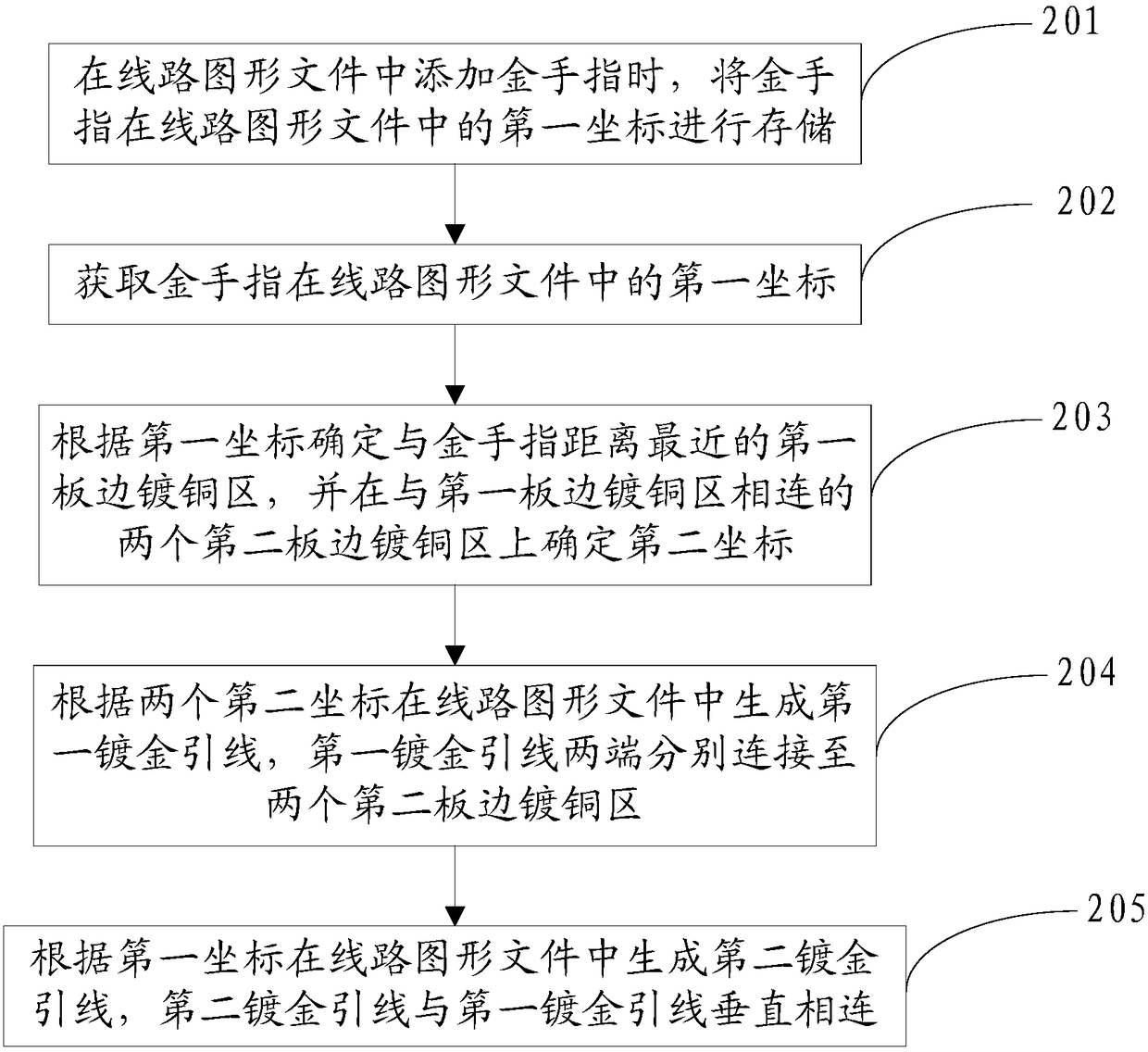

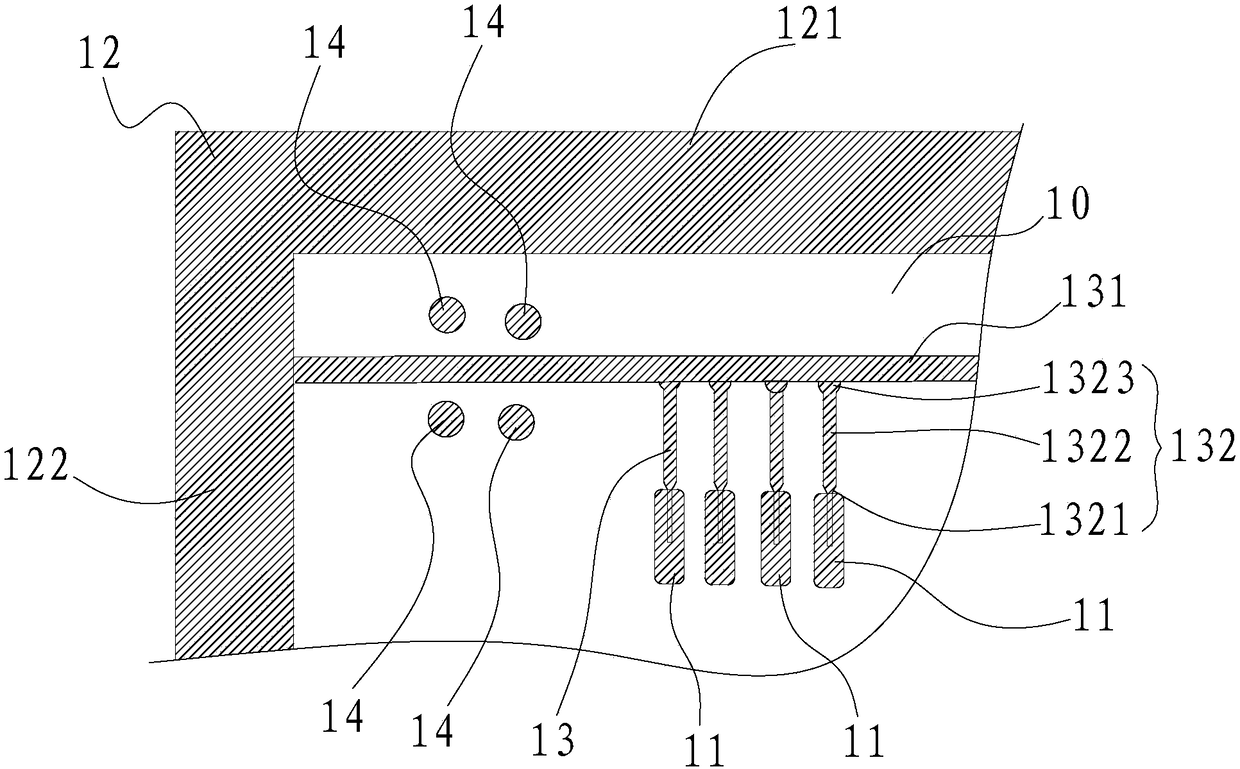

A kind of gold-finger gold-plated lead wire adding method

ActiveCN105960100BEasy to addReduce human judgmentPrinted circuit aspectsCAD circuit designGraphicsCopper plating

The invention discloses a gold-plating lead adding method for golden fingers. The gold-plating lead adding method comprises the following steps: after the golden fingers in a circuit graphic file are added successfully, obtaining the first coordinates of the golden fingers in the circuit graphic file, and determining the second coordinates of connecting positions of gold-plating leads and plate edge copper-plating areas in the circuit graphic file according to the first coordinates; and generating the gold-plating leads for connecting the first coordinates and the second coordinates in the circuit graphic file according to the first coordinates and the second coordinates. According to the gold-plating lead adding method for the golden fingers, the gold-plating leads are automatically generated in the circuit graphic file according to the coordinates of the golden fingers in the circuit graphic file, and that leads are manually added in the circuit graphic file in the prior art is not needed. In this way, when the circuit graphic file is manufactured, artificial judgment is reduced, errors caused by manual addition are avoided, and the gold-plating leads are conveniently added to the golden fingers, so that the work efficiency is improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Inspection method and inspection system

ActiveCN105784732BSafe and fast supervisionReduce human judgmentMaterial analysis by transmitting radiationComputer scienceTransmission image

Owner:NUCTECH CO LTD

A method for estimating the remaining mileage of electric UAV

ActiveCN105759218BReduce difficulty of useReduce human judgmentElectrical testingSimulationEngineering

Owner:天津飞马机器人科技有限公司

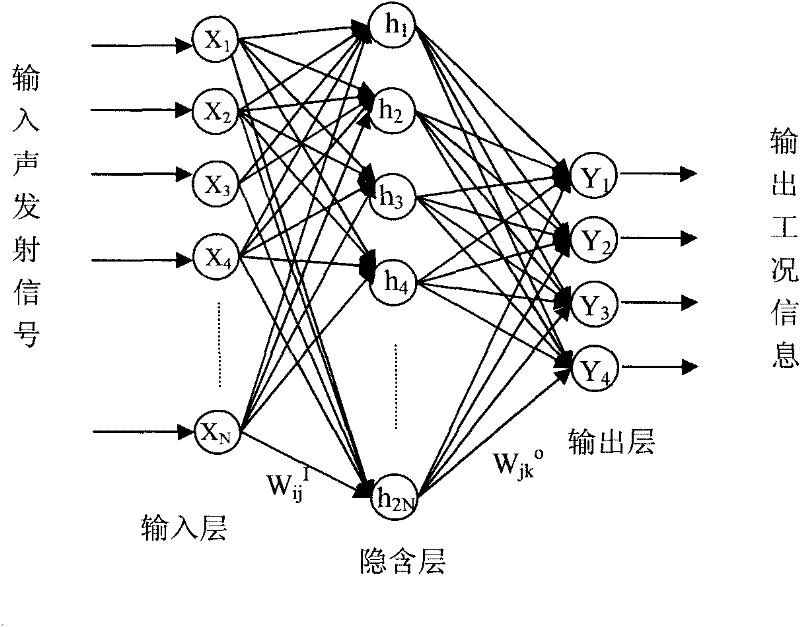

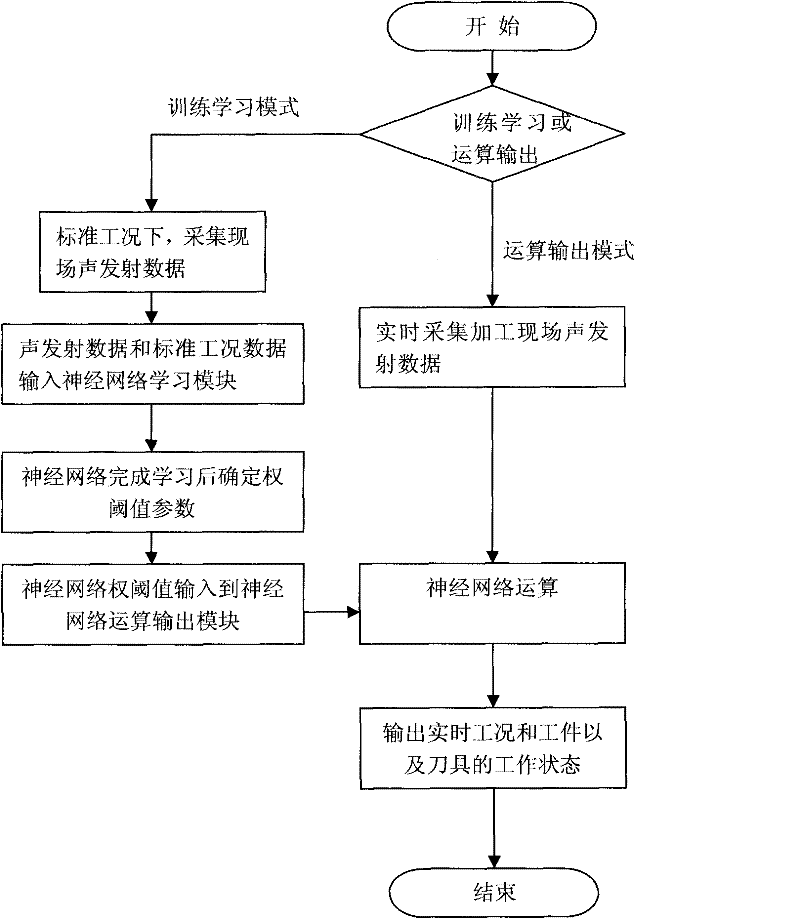

Neural network-based grinding machining working condition detection method

ActiveCN101817163BAutomatically judge processing statusAvoid damageMaterial analysis using acoustic emission techniquesGrinding feed controlReal-time dataNeural network learning

The invention discloses a neural network-based grinding machining working condition detection method, which comprises the following steps of: establishing a neural network model; acquiring field acoustic emission information under a standard working condition by using a sensor information acquisition module, inputting a sample library consisting of the acquired acoustic emission data and standardworking condition data into a neural network learning module, obtaining a weight threshold parameter by using an error back propagation algorithm and outputting the weight threshold parameter to a neural network operation and output module; according to a received real-time data vector, performing an operation and outputting a real-time working condition vector by using the neural network operation and output module; and judging the conditions of a cutter and a work piece according to definitions of each component in the working condition vector. The method has the advantages that: by utilizing a learning and intelligent judgment function of a neural network, the machining conditions of the work piece and the cutter can be automatically judged, dependence on specialized workers is greatlyreduced and machining efficiency is improved, artificial judgment factors can be effectively reduced, machining efficiency and machining quality are improved and unnecessary damages to the work pieceand the cutter are avoided.

Owner:NANJING UNIV +1

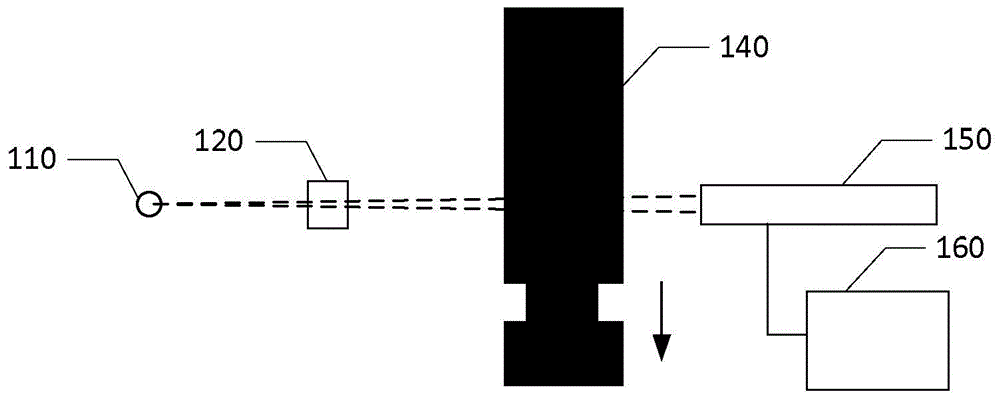

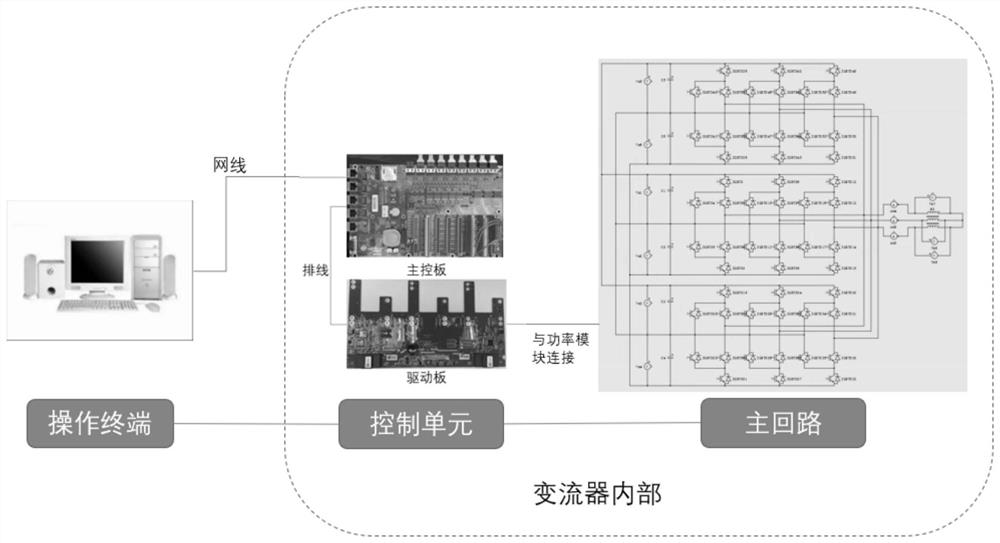

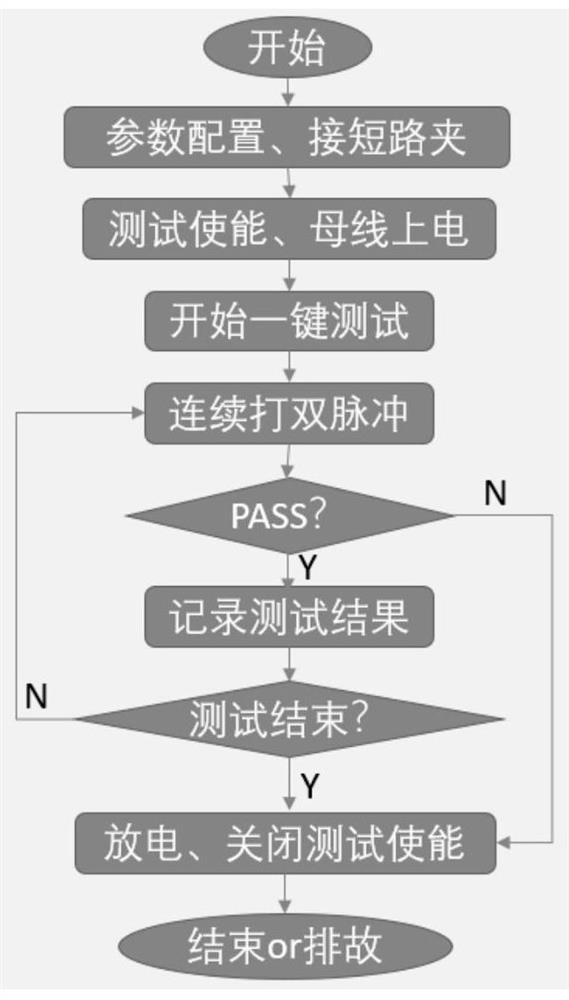

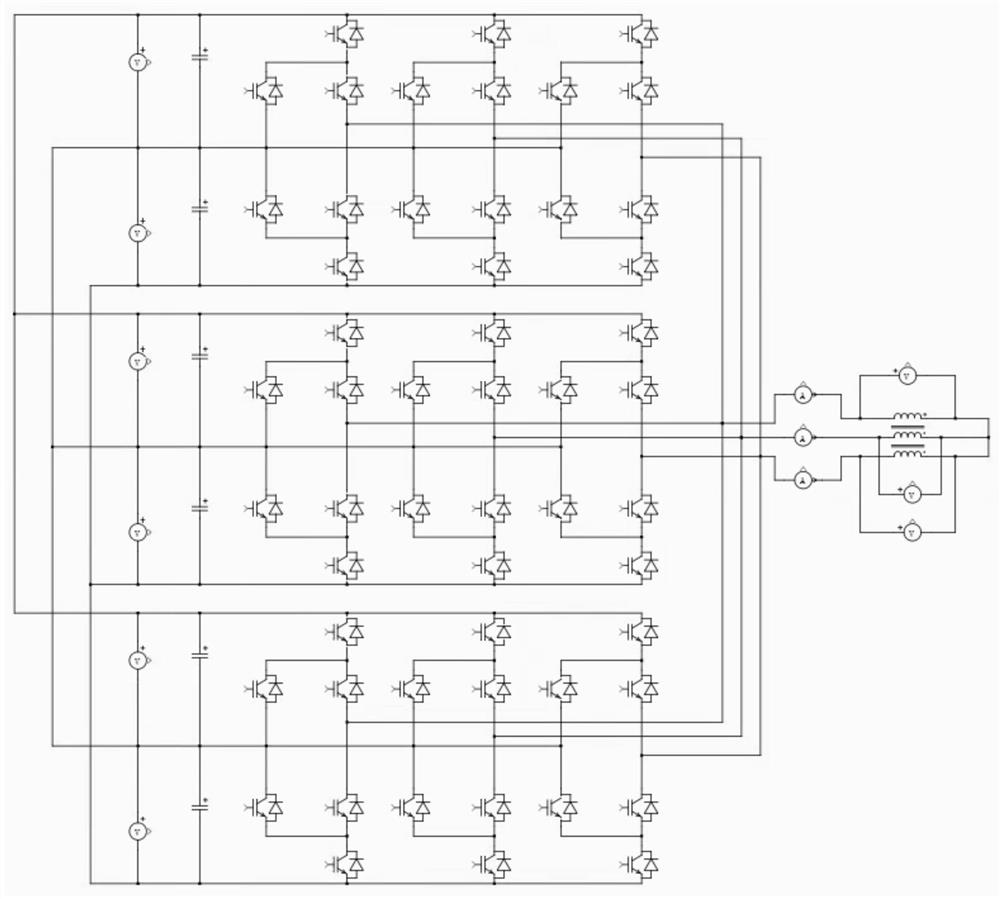

Converter test platform and test method

PendingCN113484714ATime-consuming to solveSolve benefitsIndividual semiconductor device testingCurrent transducerTest power

The invention provides a converter test platform and test method, and the platform comprises: an operation terminal which is configured to provide a test instruction for a control unit; a control unit which is configured to provide a test signal for the tested main loop according to the test instruction; and a tested main loop which is configured to form a test circuit of the tested power module by a bus BUS, a voltage sensor, a current sensor, an alternating current reactor and the tested power module, and generates test data according to the performance of the tested power module, wherein the control unit and the tested main loop are located in the converter.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD +1

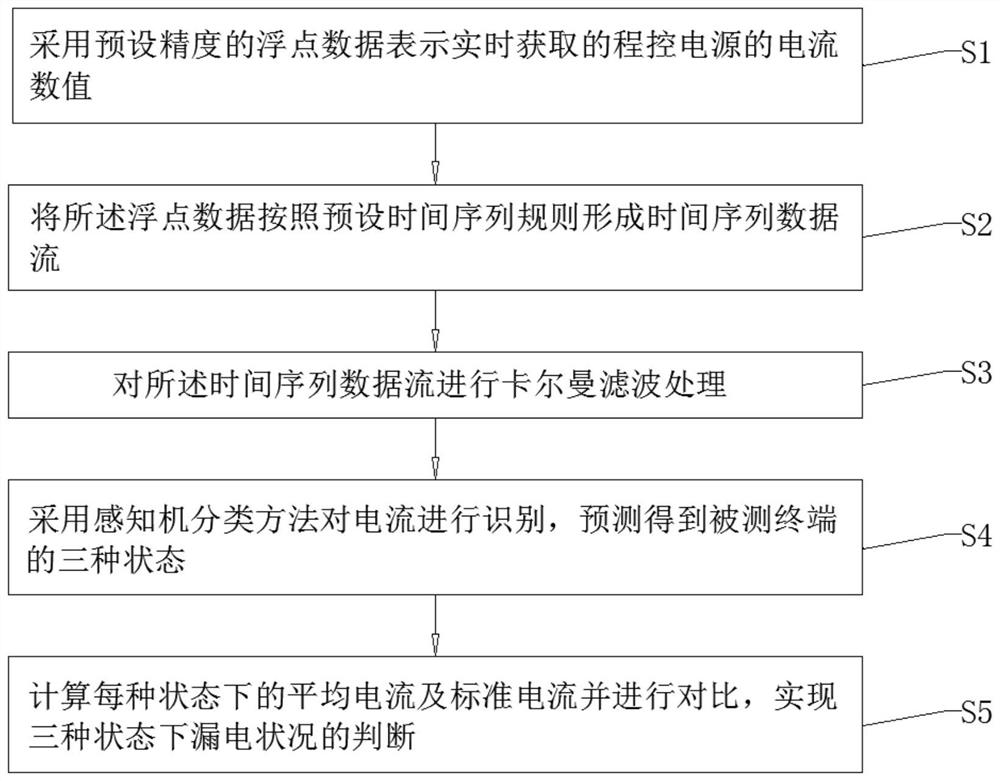

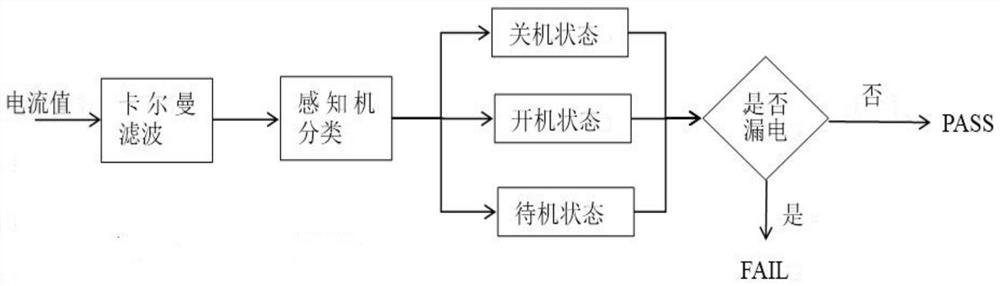

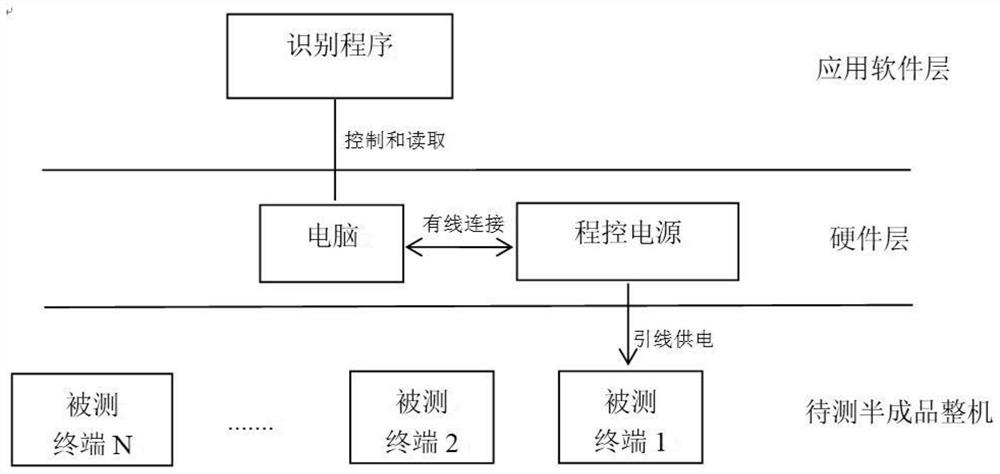

Sensing method and system for analyzing working state of intelligent terminal through current

PendingCN113986972AAutomate analysisReduce human judgmentData processing applicationsDigital data information retrievalStandby currentSequence rule

The invention discloses a sensing method and system for analyzing the working state of an intelligent terminal through current. The method comprises the following steps: adopting floating point data with preset precision to represent the current value, obtained in real time, of a programmable power supply; forming the floating point data into a time sequence data stream according to a preset time sequence rule; performing Kalman filtering processing on the time sequence data stream; identifying the current by adopting a perceptron classification method, and predicting to obtain three states of the tested terminal; and calculating the average current and the standard current in each state and comparing the average current and the standard current to judge the electric leakage conditions in the three states. The invention has the advantages that: prediction of three basic states including shutdown current and state, startup current and state and standby current and state can be achieved, whether the mainboard leaks electricity in the three states or not is judged, errors caused by manual test of current data are avoided, the labor capacity and operation complexity of production line workers are reduced, the production line efficiency and accuracy are improved, and the yield of products is improved.

Owner:江西联淦电子科技有限公司

A method for determining causality of key variables in complex industrial processes

ActiveCN108171142BLow resolution accuracyTake advantage ofCharacter and pattern recognitionComplex mathematical operationsTime lagEconomic benefits

The invention discloses a method for determining the causal relationship of key variables in a complex industrial process. The optimal time-series embedding dimension of each key variable is calculated by using the pseudo-nearest neighbor idea on the historical data of the key variables whose causal relationship is to be determined in the industrial process; Two key variables, assuming a causal relationship, using the assumed optimal time-series embedding dimension of the dependent variable as the standard, construct the time-series reconstruction manifold of the two key variables, and use the convergent cross-mapping algorithm to calculate the convergent cross-mapping ability between the two; based on Monte Carlo simulation determines the threshold of CCM capability judgment, so as to determine the correctness of the assumed causal relationship between key variables, so as to construct the preliminary causal relationship network of key variables in the industrial process; use the time-delay detection method to correct the preliminary causal relationship network, and obtain the final Key variable causality network. The invention makes full use of production off-line data, has no interference effect on the production process, and improves safety and economic benefits.

Owner:CENT SOUTH UNIV

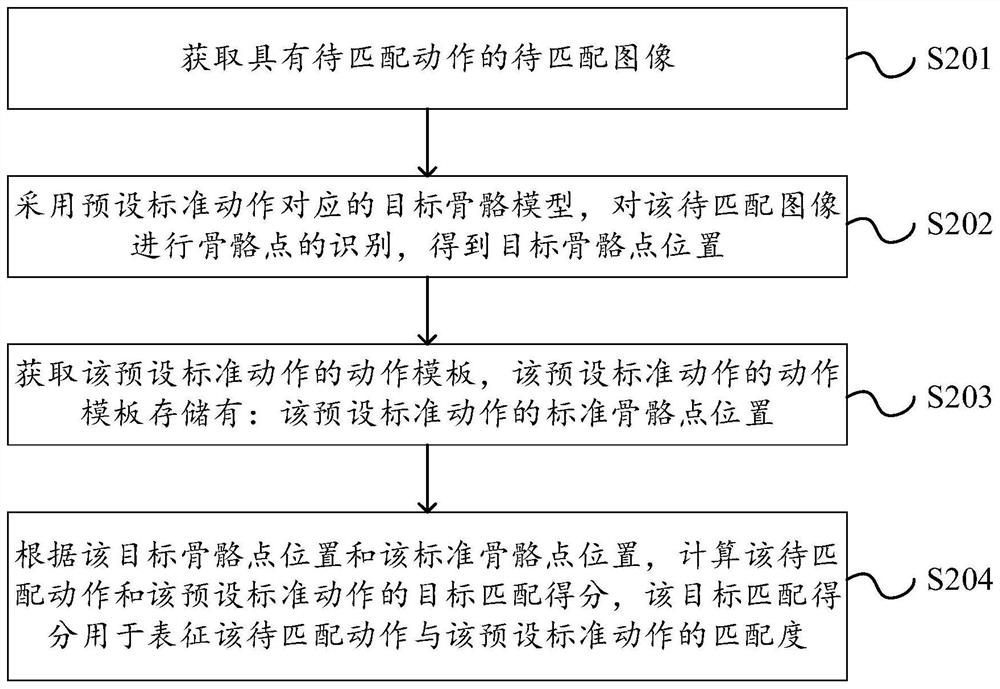

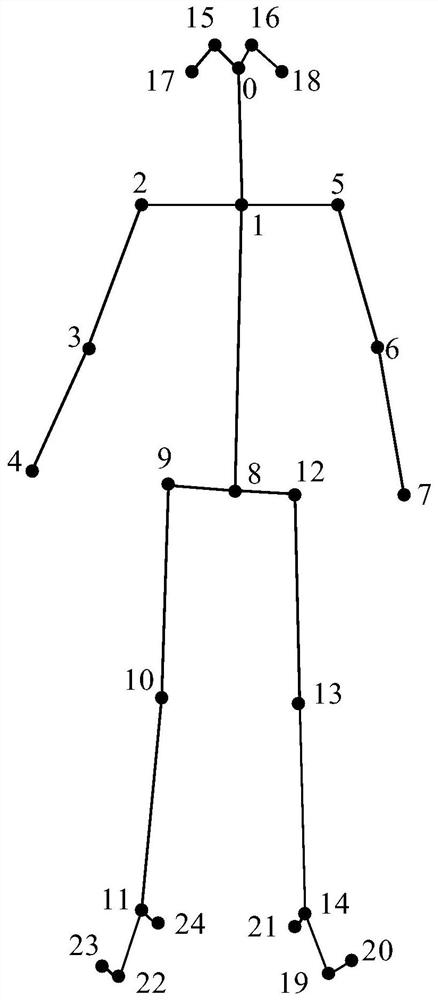

Action matching method, device and equipment and storage medium

PendingCN112434639AUnlimited number of peopleEnsure consistencyData processing applicationsCharacter and pattern recognitionTraining assessmentMatching methods

The invention provides an action matching method, device and equipment and a storage medium, and relates to the technical field of action recognition. The method comprises the steps of obtaining a to-be-matched image with a to-be-matched action; adopting a target skeleton model corresponding to a preset standard action to perform skeleton point identification on the to-be-matched image to obtain atarget skeleton point position; obtaining an action template of the preset standard action, wherein the action template of the preset standard action stores a standard skeleton point position of thepreset standard action; and according to the target skeleton point position and the standard skeleton point position, calculating a target matching score of the to-be-matched action and the preset standard action, wherein the target matching score is used for representing the matching degree of the to-be-matched action and the preset standard action. The training requirements of action requirements can be met, the human participation degree is reduced, the training assessment quality is improved, and the consistency of assessment standards is guaranteed.

Owner:ZHENGZHOU J&T HI TECH

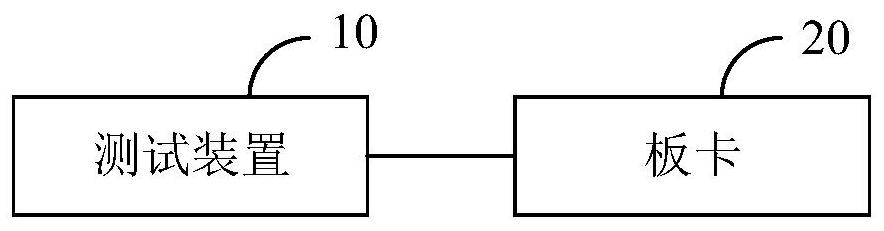

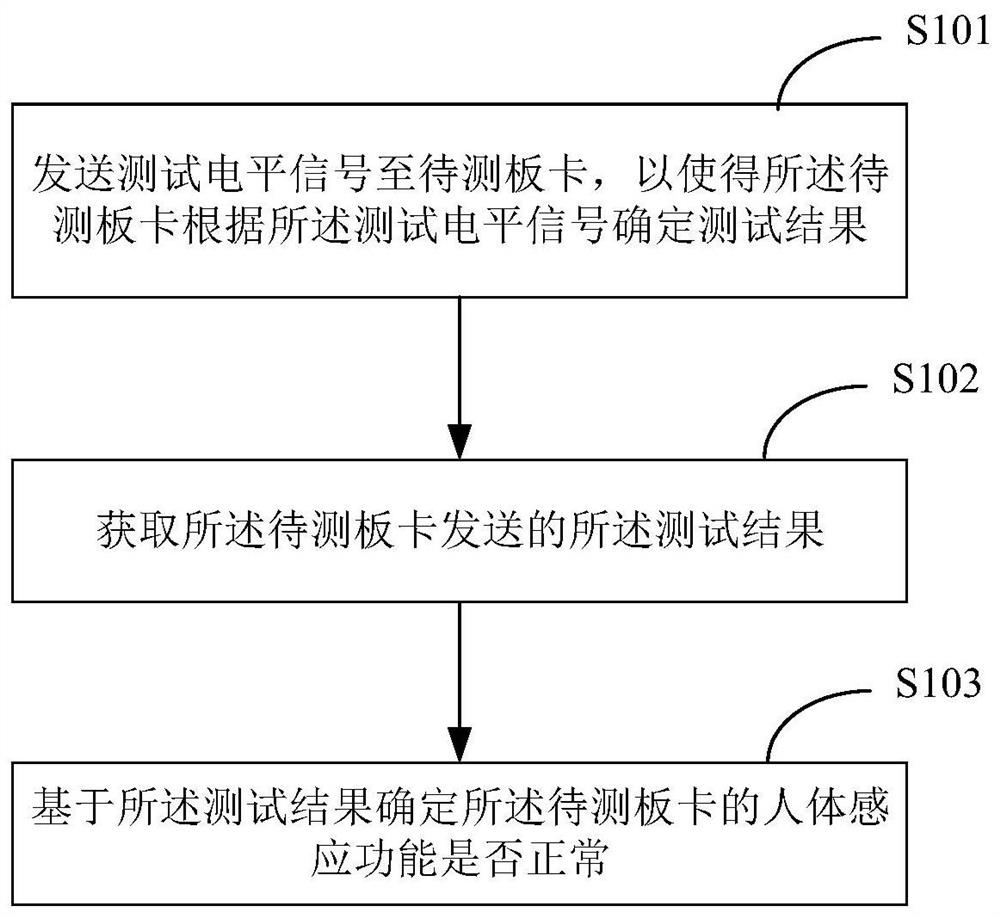

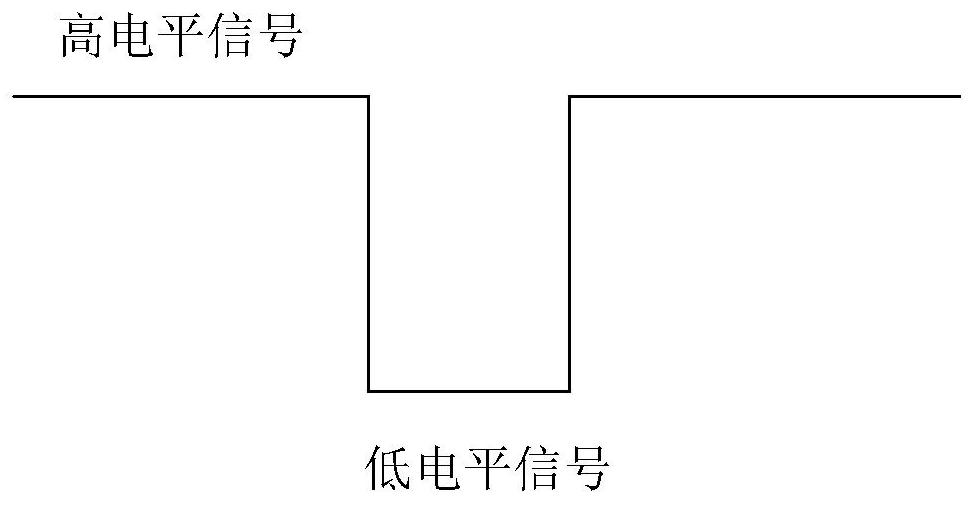

Method and device for testing human body induction function of board card and terminal equipment

ActiveCN113295983AReduce manual operationsReduce human judgmentElectronic circuit testingHuman bodyTerminal equipment

The invention is suitable for the technical field of testing, and provides a method and device for testing the human body induction function of a board card and terminal equipment, and the method comprises the steps: a testing host sends a testing level signal to a to-be-tested board card; the to-be-tested board card obtains a test level signal sent by the test host; the to-be-tested board card detects a response level signal generated by the to-be-tested board card based on the test level signal, and determines a test result of the to-be-tested board card based on the response level signal; and the test host acquires the test result sent by the to-be-tested board card, and determines whether the human body induction function of the to-be-tested board card is normal based on the test result. When the to-be-tested board card is tested, human sensing equipment does not need to be plugged, manual operation is omitted, the working efficiency is improved, automatic judgment is achieved, and the testing accuracy is improved.

Owner:东莞市金锐显数码科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com