A kind of gold-finger gold-plated lead wire adding method

A gold-plated lead wire and gold finger technology, which is applied in the field of gold-plated lead wire addition, can solve problems such as low work efficiency, many steps of human judgment, and error-prone, so as to improve work efficiency, avoid manual adding errors, and reduce human judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

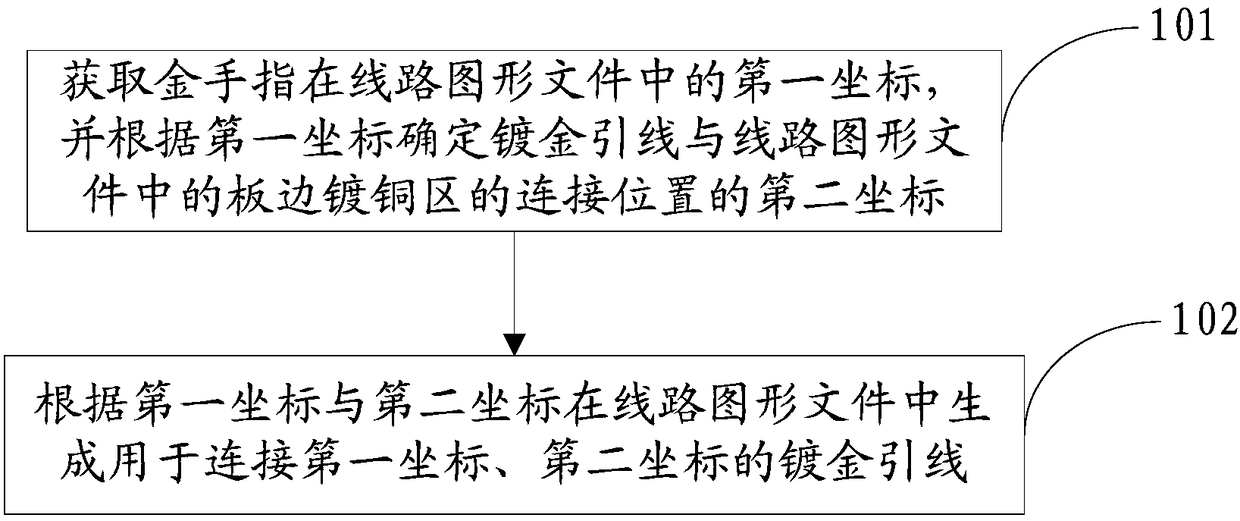

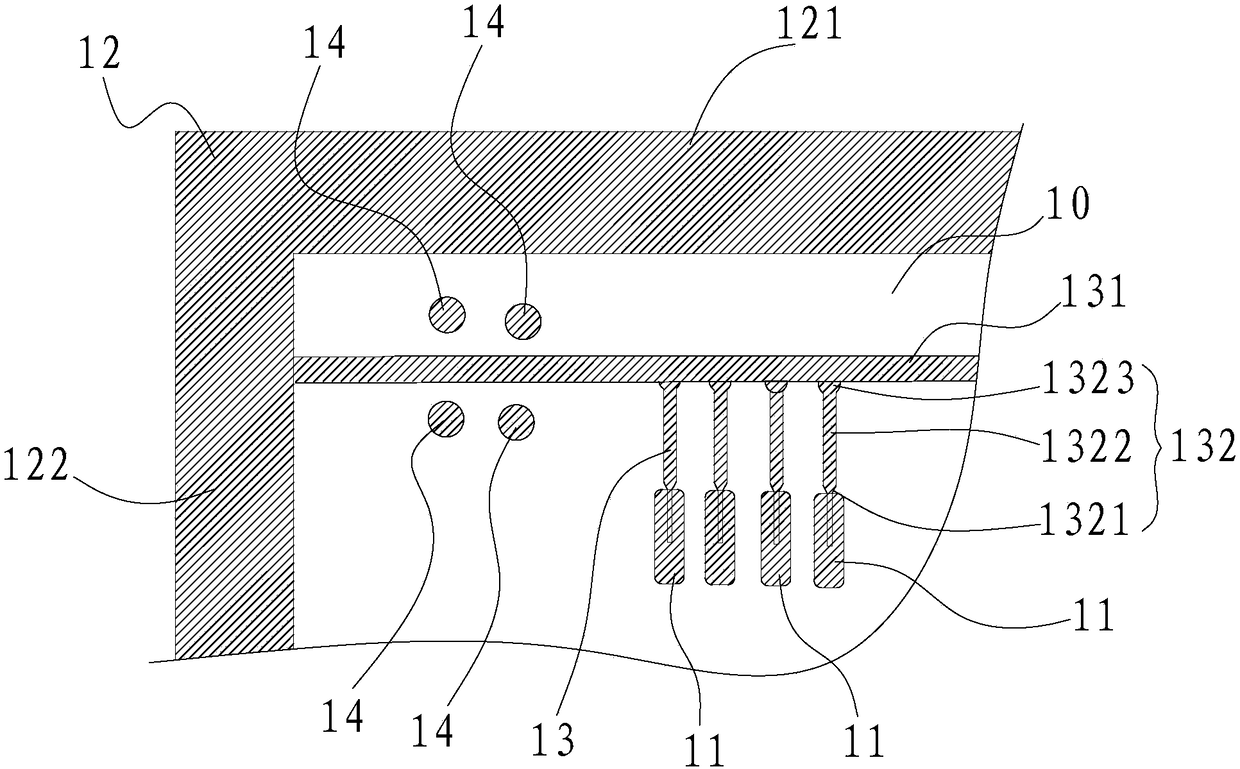

[0027] Such as figure 1 , 3 And shown in 4, golden finger gold-plated lead wire adding method of the present invention, comprises the steps:

[0028] Step S101, after the gold finger 11 in the circuit graphic file 10 is successfully added, obtain the first coordinates of the gold finger 11 in the circuit graphic file 10, and determine the relationship between the gold-plated lead 13 and the The second coordinate of the connection position of the board edge copper plating area 12 in the circuit pattern file 10;

[0029] Step S102 , generating the gold-plated leads 13 for connecting the first coordinates and the second coordinates in the line graphic file 10 according to the first coordinates and the second coordinates.

[0030] The above-mentioned gold-finger gold-plated lead adding method automatically generates gold-plated lead 13 in the circuit graphic file 10 according to the coordinates of the gold finger 11 in the circuit graphic file 10, without manually adding it in t...

Embodiment 2

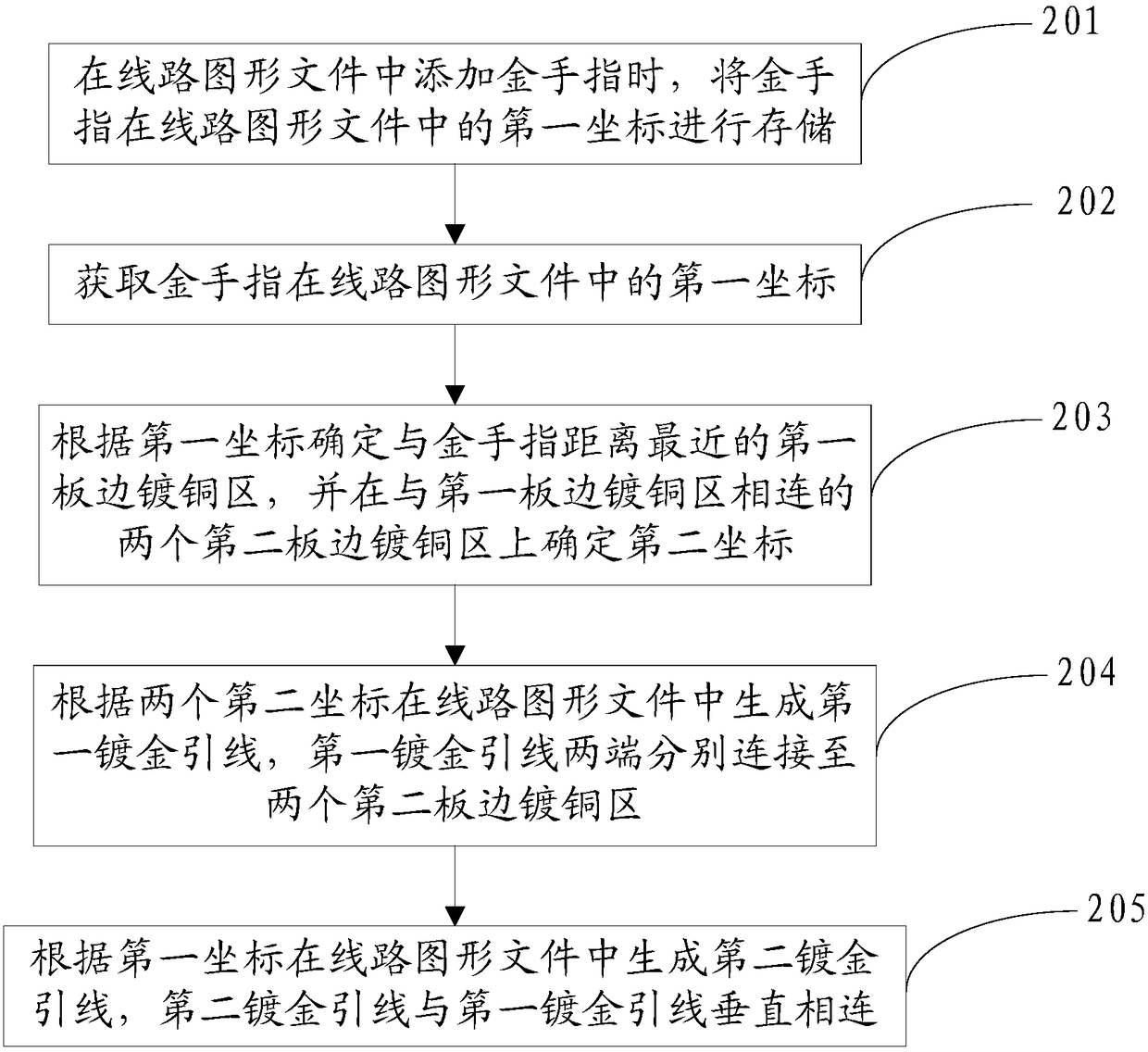

[0032] see figure 2 , 3 And 4, gold finger gold-plated lead wire adding method of the present invention, comprises the steps:

[0033] Step S201, when adding the golden finger 11 in the circuit graphic file 10, storing the first coordinates of the cheat 11 in the circuit graphic file 10;

[0034] Step S202, after the gold finger 11 in the line graphic file 10 is successfully added, obtain the first coordinate of the cheat 11 in the line graphic file 10;

[0035] Step S203: Determine the first board edge copper plating area 121 closest to the gold finger 11 according to the first coordinates, and plate two second board edge copper plating areas 121 connected to the first board edge determining the second coordinates on the copper zone 122;

[0036] Step S204, generating the first gold-plated leads 131 in the circuit graphics file 10 according to the two second coordinates, and the two ends of the first gold-plated leads 131 are respectively connected to two copper-plated ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com