Artificial neural network-based method and device for automatically trimming grinding wheel of grinding machine

A technology of artificial neural network and dressing device, which is applied in the field of automatic dressing method and dressing device of grinding machine grinding wheel, which can solve problems such as difficult installation and debugging, complex structure, unfavorable work efficiency and guaranteed product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

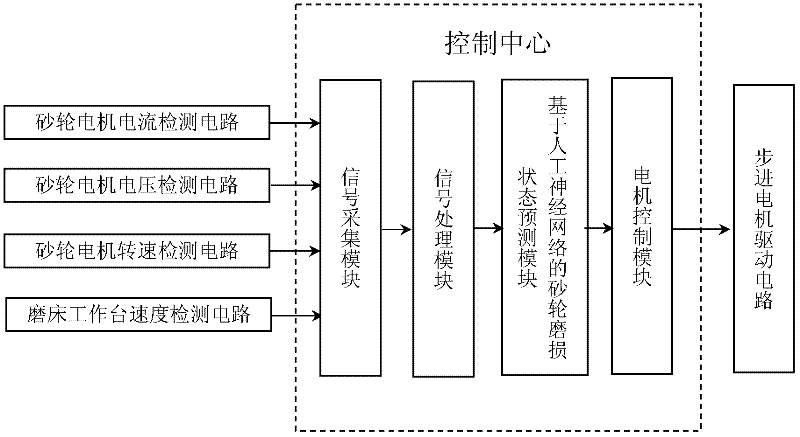

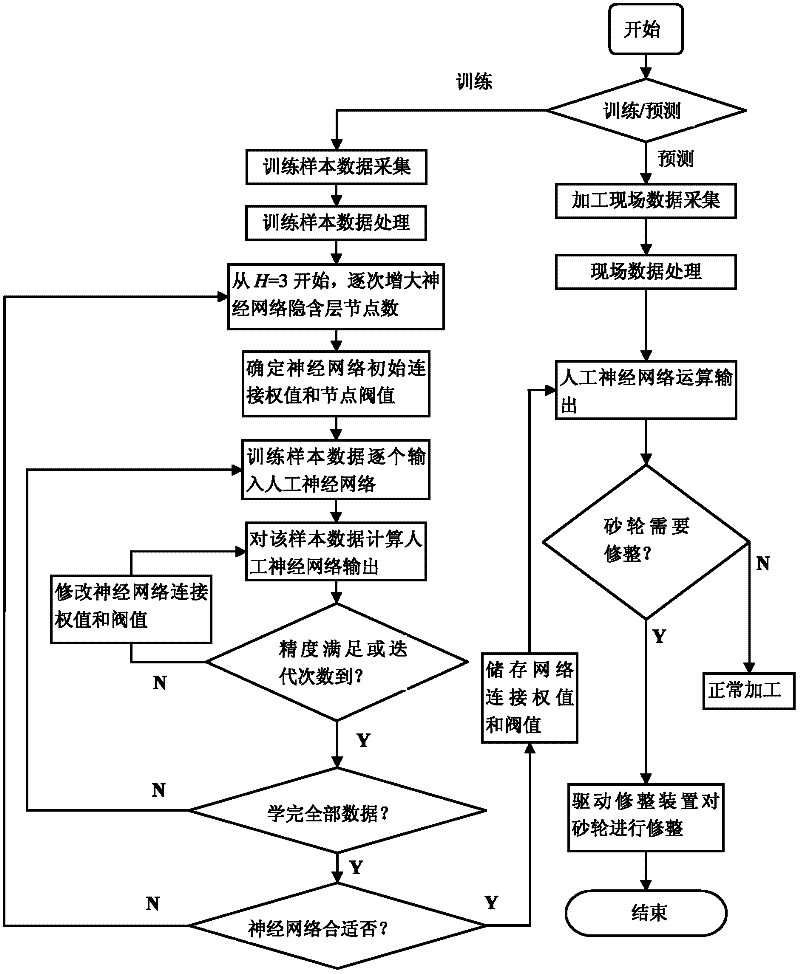

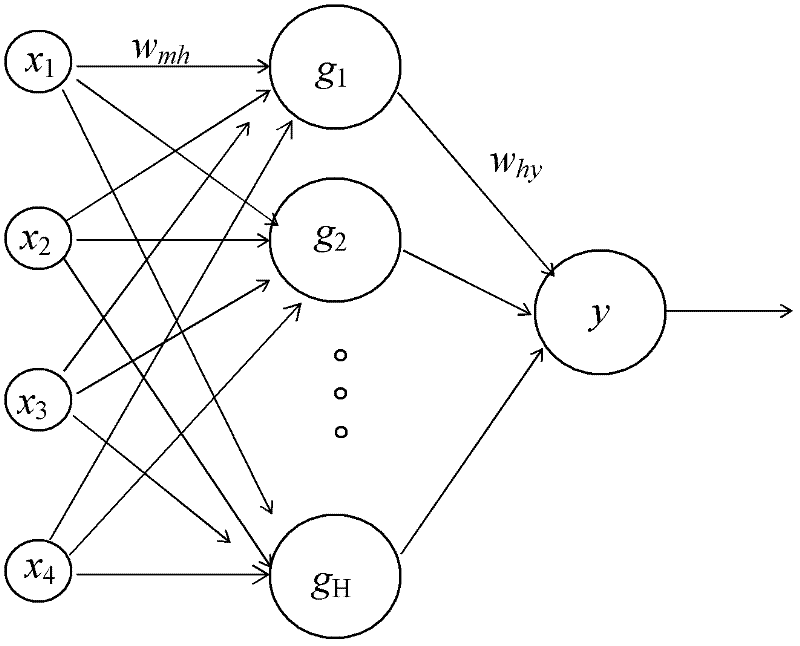

[0047] see figure 1 , a kind of artificial neural network based grinding wheel automatic dressing device designed by the present invention is mainly composed of dressing tools, slide table, stepping motor, screw mandrel and numerical control system. Wherein the dressing tool is located above the top of the grinding wheel of the grinding machine, and the dressing tool is installed on the slide table, the slide table is connected with the output end of the stepping motor through the screw rod, and the input end of the stepping motor is connected with the numerical control system. The numerical control system above includes a control center, a grinding wheel motor current detection circuit, a grinding wheel motor voltage detection circuit, a grinding wheel motor speed detection circuit, a grinding machine table speed detection circuit and a stepping motor drive circuit. The control center is equipped with a signal acquisition module, a signal processing module, an artificial neur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com