Transformer high-voltage outgoing line integration system

A high-voltage outlet, transformer technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, electrical components, etc., can solve the problem that the spacing does not meet the minimum spacing requirements, the power plant layout occupies a large area, etc. problems, to achieve the effect of reducing the space occupied by the layout, reducing the space occupied, and ensuring the safety of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

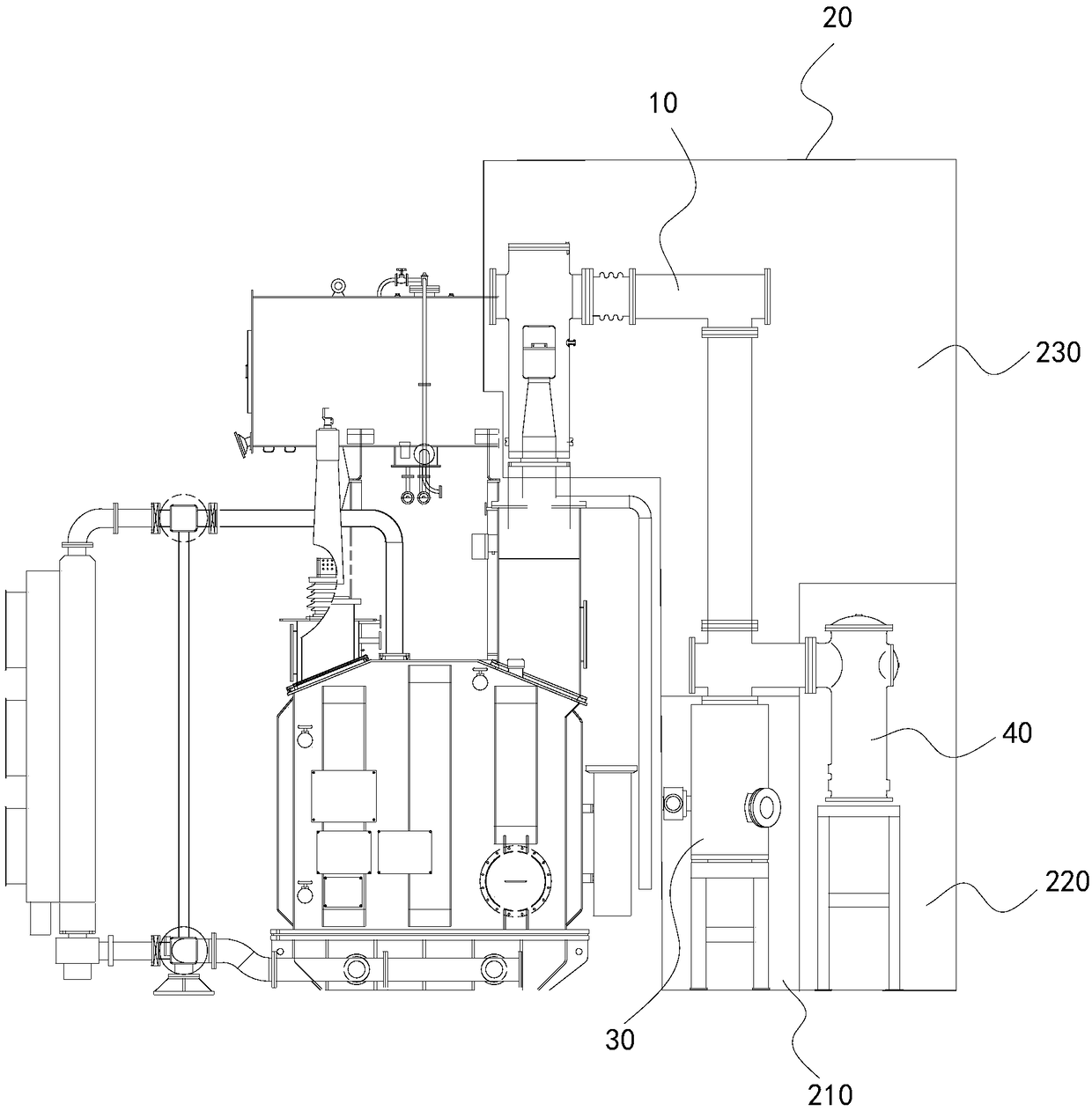

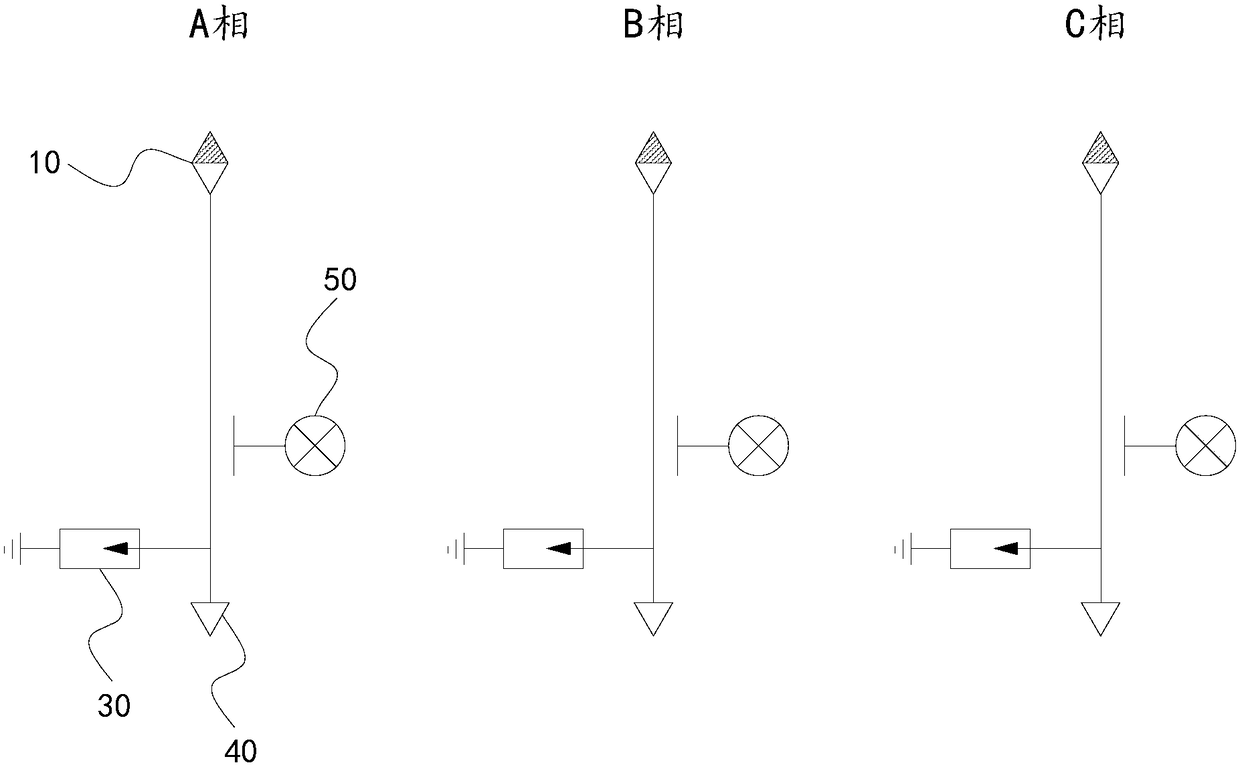

[0022] Such as figure 1 and figure 2 As shown, a transformer high-voltage outgoing line integration system, the transformer is provided with a high-voltage outgoing line terminal 10, the transformer high-voltage outgoing line integration system includes an airtight sleeve 20, a lightning arrester 30, and a high-voltage bushing 40, and the lightning arrester 30, high-voltage bushing 40 and high-voltage outgoing line terminals Both are located in the airtight sleeve 20 , the arrester 30 and the high voltage bushing 40 are respectively electrically connected to the high voltage outlet terminal 10 , and the airtight sleeve 20 is filled with insulating gas.

[0023] The lightning arrester 30, the high-voltage bushing 40 and the high-voltage outlet terminal are arranged in the airtight sleeve 20, and the connection method of the overhead jumper is no longer used, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com