Box type transformer station framework structure and application thereof

A box-type substation and frame structure technology, applied in enclosed substations, substations, substations/distribution device enclosures, etc., can solve problems such as inability to standardize and standardize production, achieve broad application prospects and promotion value, high safety factor, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

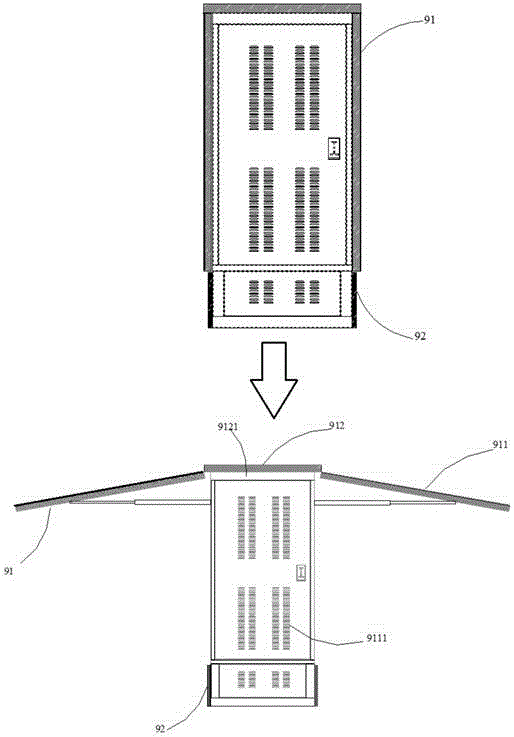

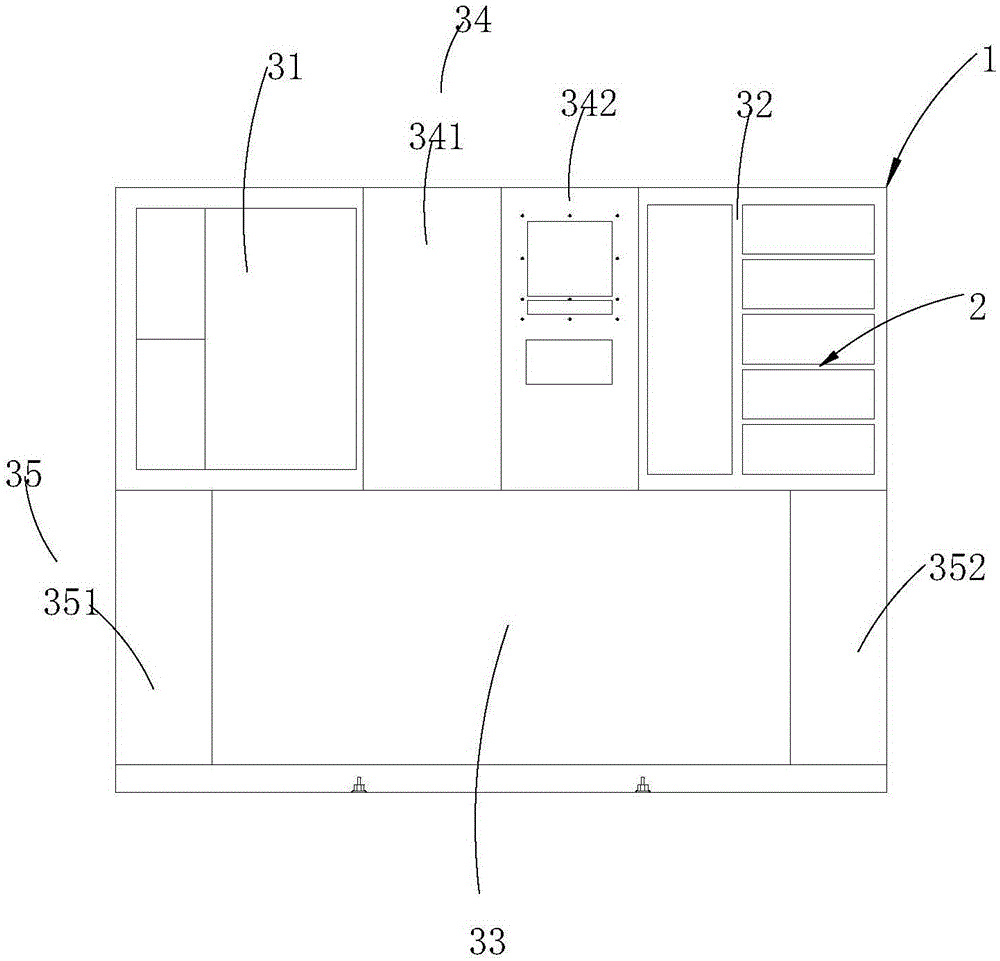

[0044] The invention provides a box-type substation frame structure, figure 1 It is a structural schematic diagram of the frame structure of the box-type substation, such as figure 1 As shown, the frame structure of the box-type substation is a frame structure of a 10KV box-type substation that implements national and industry design, process and inspection standards, and can be standardized and mass-produced. It includes a frame body 1 and a plurality of partitions and / or panels 2. The frame body 1 and the partition boards 2 cooperate to form the frame of each functional room area of the box-type substation, specifically the high-voltage switch room area 31, the low-voltage switch room area 32, Transformer room area 33, metering room area 34, and cable room area 35 are five functional room areas, respectively corresponding to the high-voltage switch room, low-voltage switch room, transformer room, metering room and cable room; further, the cable room area 35 is divided into...

Embodiment 2

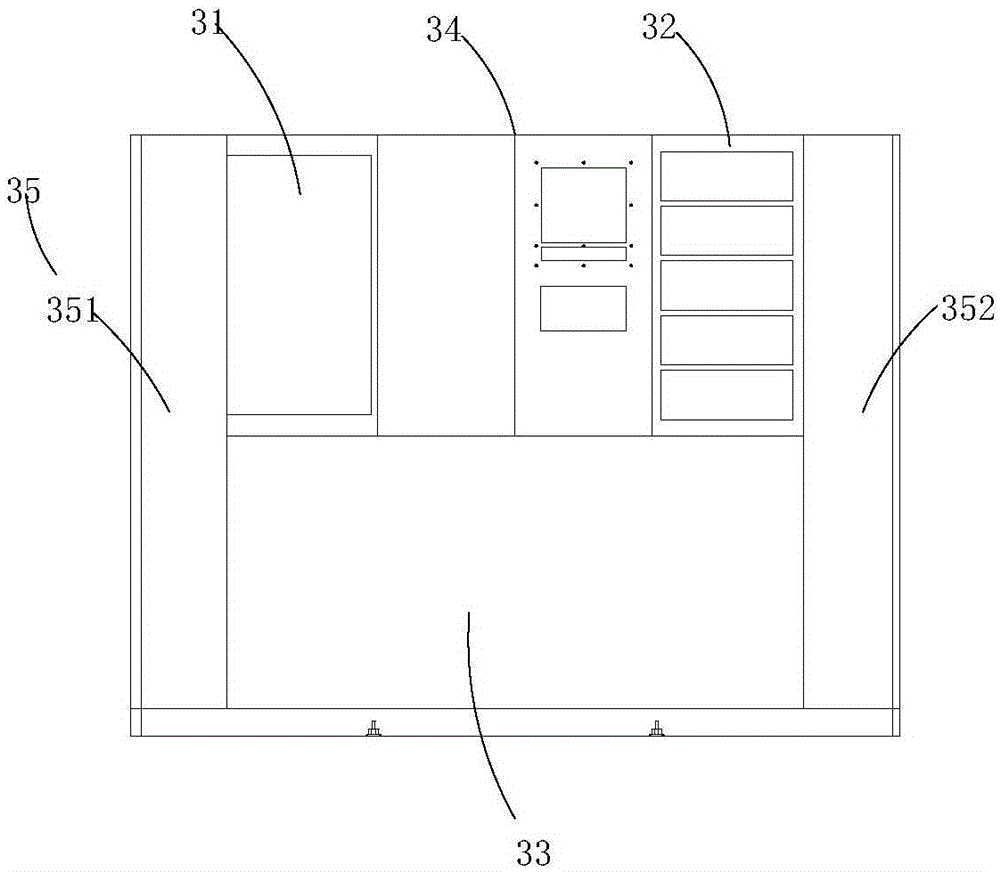

[0049] figure 2 The frame structure of the box-type substation shown is another preferred embodiment provided by the present invention, and differs from Embodiment 1 only in the structure and layout of the cable room area 35 . Such as image 3 As shown, the cable room area 35 includes a high-voltage cable room area 351 and a low-voltage cable room area 352. There is a two-layer structure between the high-voltage cable room area 351 and the low-voltage cable room area 352. Along the X direction, the upper layer is the high-voltage switch room area 31 in turn. , metering room area 34 and low-voltage switch room area 32, the lower floor is the transformer room area 33; the high-voltage cable room area 351 and the low-voltage cable room area 352 are the same height as the two-layer structure respectively. The improvement of the structure and layout of the cable room area 35 can realize the upper and lower incoming lines of the frame structure of the box-type substation, and can ...

Embodiment 3

[0051] Figure 3-7 Another preferred embodiment of the box-type substation frame structure provided by the present invention is different from the above-mentioned embodiments in that the box-type substation frame structure integrates the cable room area of Examples 1-2 with the high and low voltage switch room area respectively, At this time, the frame structure of the box-type substation includes a high-voltage switch room area 31, a low-voltage switch room area 32, and a transformer room area 33. The cables entering and leaving the high-voltage and low-voltage switch room areas (31, 32) can be placed in the high-voltage switch room area 31 respectively. Or in the low-voltage switch room area 32, therefore, at this time, the box-type substation can be used in conjunction with the cable well to realize cable maintenance.

[0052] image 3 It is a schematic diagram of the frame structure of the box-type substation, such as image 3 As shown, the high-voltage switch room are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com