A brush holder assembly for an automobile radiator fan motor

A technology of automobile radiator and fan motor, which is applied to electric components, electrical components, electromechanical devices, etc., can solve the problems of poor heat dissipation effect of the brush holder plate, affecting the service life of the motor, affecting the stability of the motor, etc., and achieves the heat dissipation effect. Good, noise reduction, firm installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through specific examples.

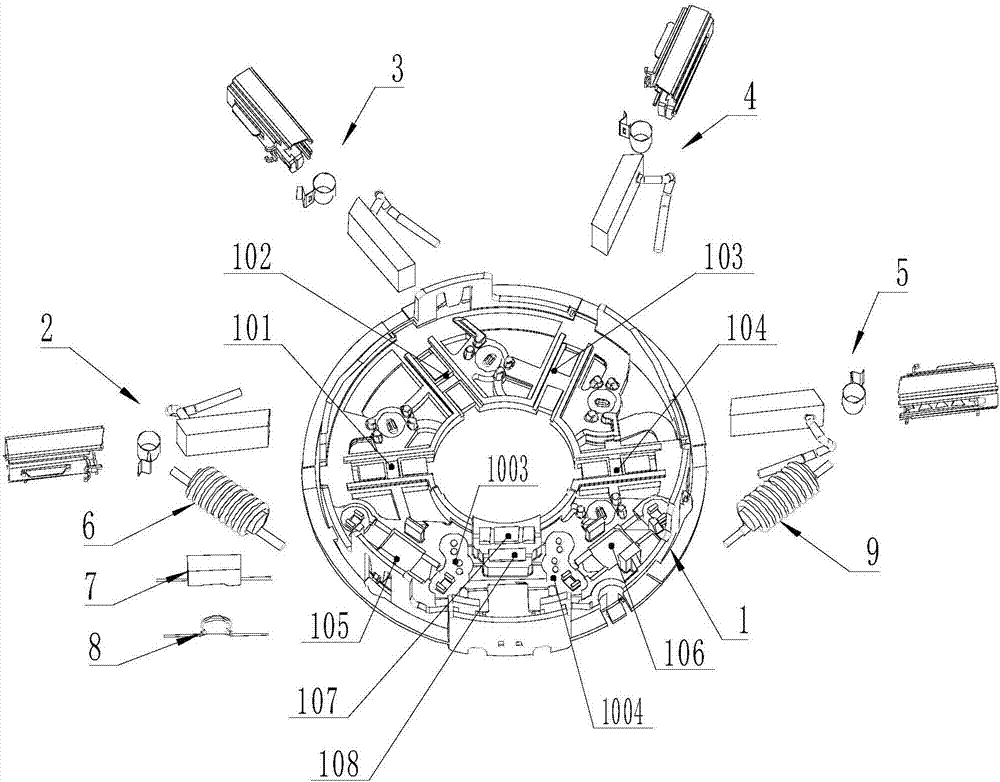

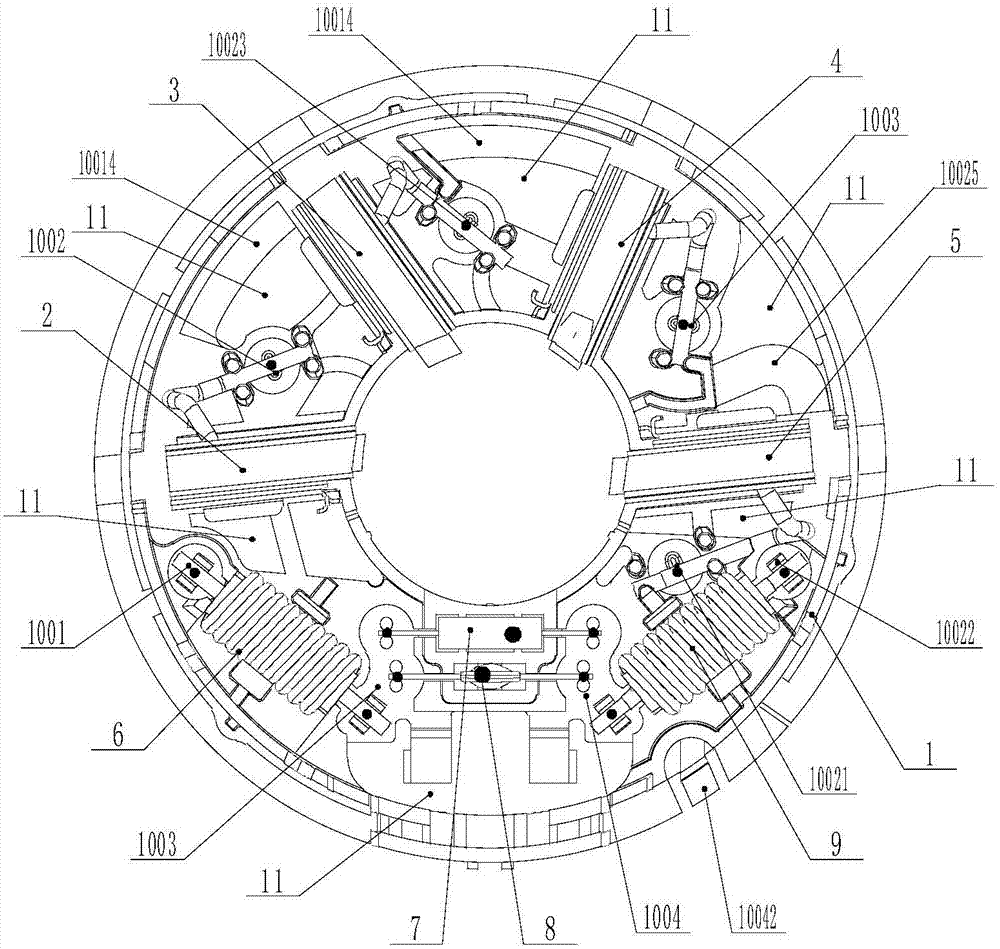

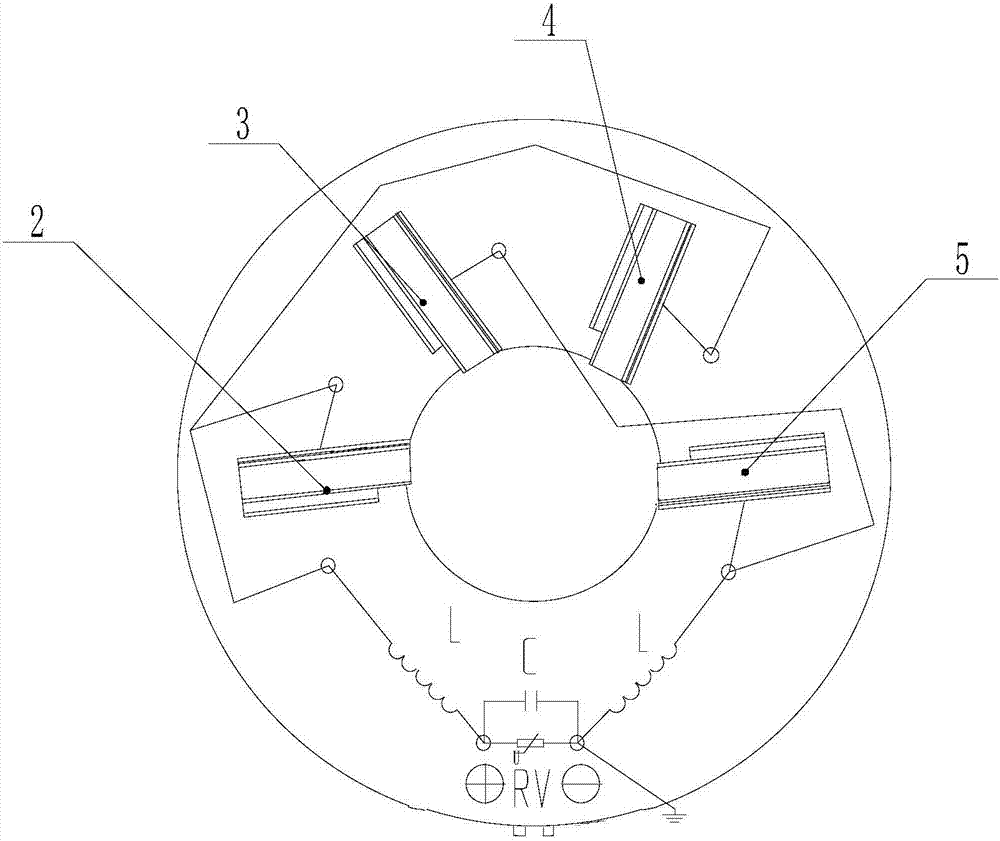

[0033] Such as figure 1 , 2 , shown in 4, a kind of brush holder assembly for automobile radiator fan motor, comprises brush holder board, carbon brush assembly and inductor, and this brush holder board comprises brush holder board body 1 and is arranged on the conductive metal of brush holder board body 1 Component 10, the conductive metal component 10 connects the carbon brush assembly according to the set circuit connection method, such as image 3 As shown, the brush holder plate body 1 is provided with four carbon brush installation areas and two inductance installation areas, wherein the number of the carbon brush installation areas is four and is respectively located at the center of the center hole of the brush holder plate body. At the 0° position 101, the 60° position 102, the 120° position 103 and the 180° position 104 of the brush holder plate body, the carbon brus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com