Electrochemical cell and method for the production thereof

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve the problems of ceramic layer peeling, ceramic layer lack of elasticity, fracture, etc., and achieve the effect of flexible implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

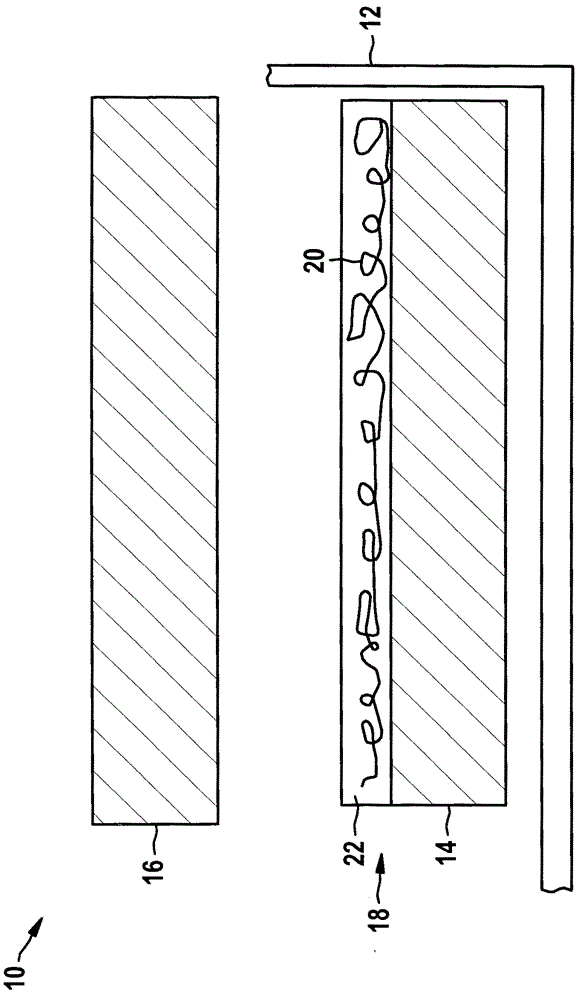

[0023] A battery cell 10 according to an embodiment of the invention is schematically shown in FIG. 1 . The battery cell 10 includes a housing 12 in which the electrochemical components of the battery cell 10 are mounted. Particularly preferably, lithium-containing anode 14 and cathode 16 belong to the electrochemical component. If battery cell 10 is embodied, for example, as a lithium-air battery, anode 14 includes metallic lithium, for example in the form of elemental lithium or a lithium alloy.

[0024] In this case, the cathode 16 can be embodied as an air electrode or an oxygen electrode, for example.

[0025] In order to protect the anode 14 , for example against the ingress of ambient constituents which react with the elemental lithium, such as in particular water vapor or oxygen, the anode 14 has, for example, a protective layer 18 . In this case, the anode 14 is preferably covered substantially over its entire surface, at least on its large surface facing the cathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com