Agilawood pearl amino acid soap and preparation method thereof

An amino acid and pearl technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve problems that need to be improved, and achieve the effect of fresh and elegant fragrance, solving dull skin, and improving skin quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

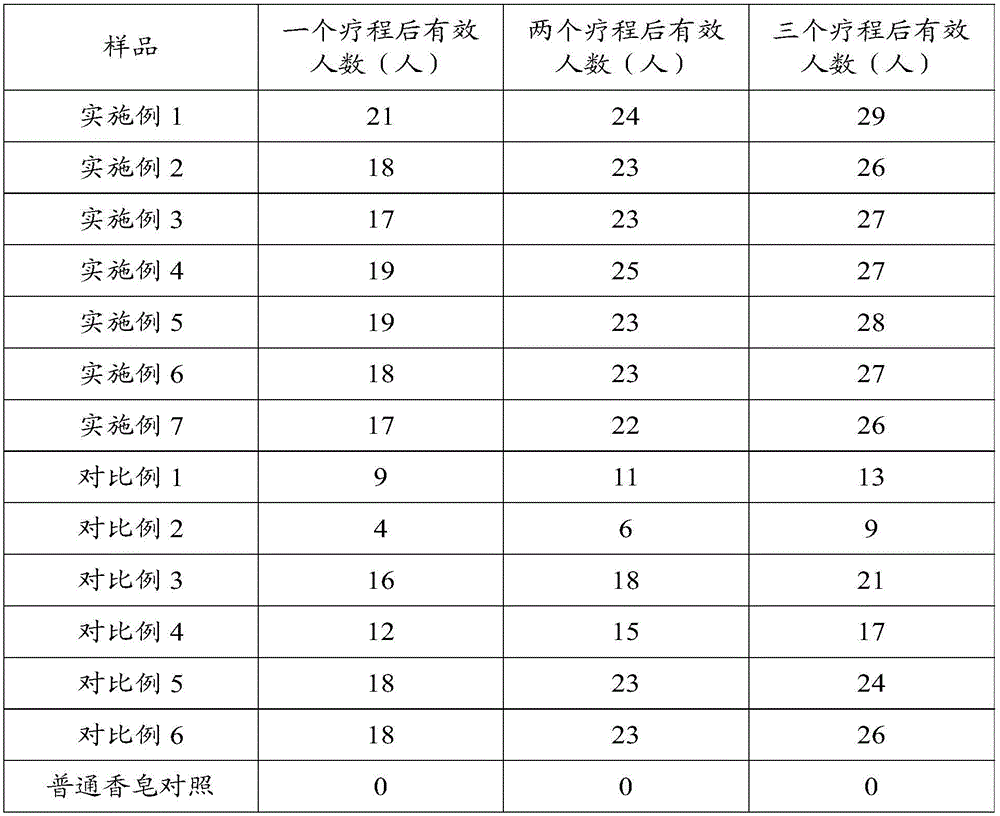

Examples

preparation example Construction

[0029] The preparation method of agarwood pearl amino acid soap of the present invention comprises the following steps:

[0030] (1) After slowly heating and dissolving cocoyl glutamic acid, stir and slowly heat up at a heating rate of 1-5°C / min to obtain solution I;

[0031] (2) Add glycerin, propylene glycol, water, triethanolamine and ethanol in sequence to solution I, and continue to stir and heat up until the raw materials are completely dissolved to obtain solution II;

[0032] (3) Add agarwood extract and pearl extract successively to solution II, and after stirring evenly, obtain solution III;

[0033] (4) The solution III is left to stand and cooled to obtain shaped Agarwood Pearl Amino Acid Soap.

[0034] In step (1), stirring needs uniform speed, and its stirring speed should not be too fast, otherwise easily cause excessive heat loss and water loss, and reduce the dissolving rate of raw material; As preferably, in step (1), the speed of stirring is 20~30r / min.

...

Embodiment 1

[0042] Take the following raw materials: 100 parts of cocoyl glutamic acid, 42.0 parts of glycerin, 22.5 parts of propylene glycol, 45 parts of water, 70 parts of triethanolamine, 5.6 parts of ethanol, 1.4 parts of agarwood extract, and 1.4 parts of pearl extract.

[0043] Follow the steps below to prepare:

[0044](1) First add cocoyl glutamic acid into the cleaned emulsification pot, slowly heat and dissolve, then start to stir continuously at 25r / min, and continue to heat up at 1°C / min to obtain solution I;

[0045] (2) Add glycerin, propylene glycol, water, triethanolamine and ethanol in the above proportions to solution I in sequence, and continue stirring at 25 r / min, and raise the temperature to 80°C until the raw materials are completely dissolved to obtain solution II;

[0046] (3) Add the agarwood extract and the pearl extract in the above dosage ratios to the solution II in sequence, and stir for 10 minutes. After the solution is uniform, the solution III is obtaine...

Embodiment 2

[0050] Take the following raw materials: 100 parts of cocoyl glutamic acid, 30 parts of glycerin, 15 parts of propylene glycol, 30 parts of water, 68 parts of triethanolamine, 5.0 parts of ethanol, 1.0 part of agarwood extract, and 1.0 part of pearl extract.

[0051] Follow the steps below to prepare:

[0052] (1) First add cocoyl glutamic acid into the cleaned emulsification pot, slowly heat and dissolve, then start to stir continuously at 25r / min, and continue to heat up at 1°C / min to obtain solution I;

[0053] (2) Add glycerin, propylene glycol, water, triethanolamine and ethanol in the above proportions to solution I in sequence, and continue stirring at 25 r / min, and raise the temperature to 80°C until the raw materials are completely dissolved to obtain solution II;

[0054] (3) Add the agarwood extract and the pearl extract in the above dosage ratios to the solution II in sequence, and stir for 10 minutes. After the solution is uniform, the solution III is obtained;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com