Air filter of oil filtering machine

A technology of air filter and oil filter, which is applied in the direction of fuel air filter, dispersed particle filtration, chemical instruments and methods, etc., which can solve the problems of high energy consumption, high maintenance cost, and large noise pollution, and achieve reduction The effect of air noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

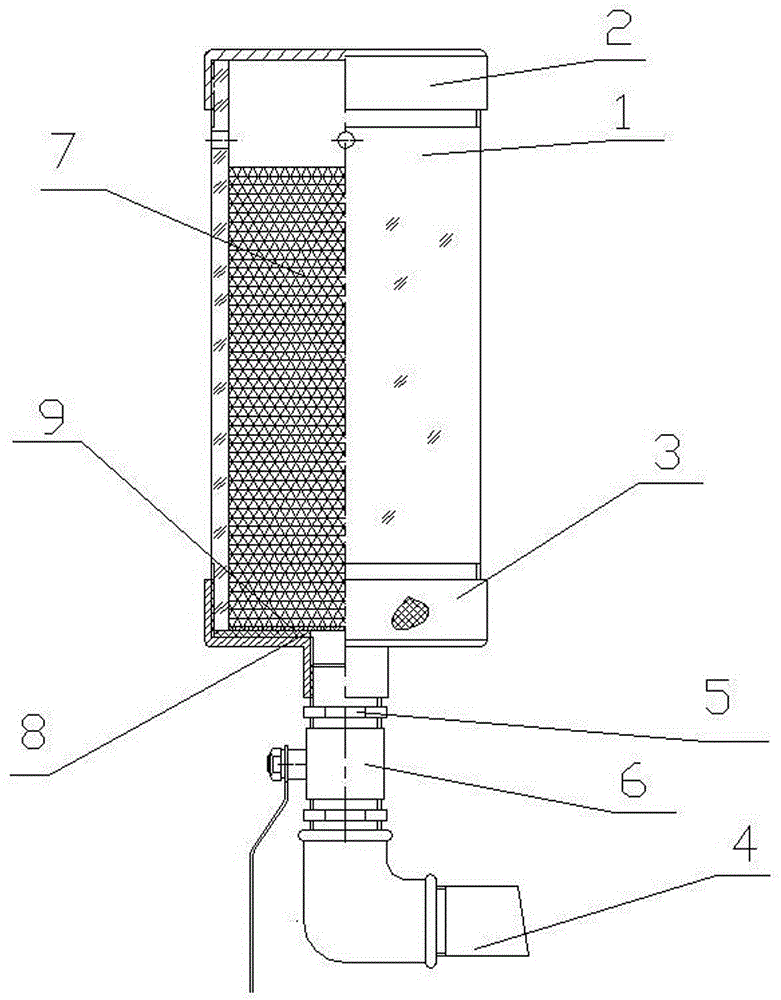

[0015] An air filter for an oil purifier, comprising a tank body 1, an upper cover 2, a base 3, a pipe joint 4, etc., characterized in that the upper cover 2 is located on the top of the tank body 1 and fits with the tank body 1, and the base 3 is located on the top of the tank body 1 The bottom of the tank body 1 fits with the tank body 1 , and the base 3 is provided with an inner joint 5 and connected with the pipeline joint 4 .

Embodiment 2

[0017] A steel ball valve 6 is provided at the joint between the inner joint 5 and the pipeline joint 4 .

Embodiment 3

[0019] The inner surface layer of the tank body 1 is made of silica gel material 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com