Ammonia and carbon dioxide separation method

A carbon dioxide and separation method technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as inability to separate, easy crystallization of ammonia and carbon dioxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

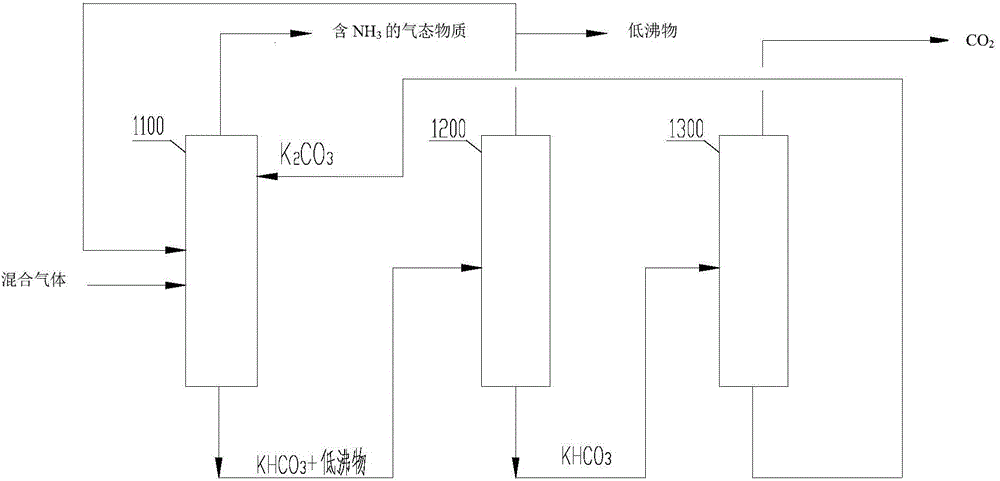

[0042] The first embodiment of the present invention relates to the process principle of a separation device for ammonia and carbon dioxide, as shown in the attached figure 1 As shown, the ammonia and carbon dioxide separation process includes: sending the mixed gas containing ammonia and carbon dioxide into a three-tower separation device including an absorption tower 1100, a recovery tower 1200 and a desorption tower 1300 for separation. First, the carbon dioxide absorption step is carried out in the absorption tower 1100: the mixed gas containing ammonia and carbon dioxide is sent into the absorption tower, and at the same time, a carbon dioxide absorbent (hereinafter also referred to as an absorbent) and low boilers are respectively introduced into the absorption tower, and the carbon dioxide absorbent Contains potassium carbonate solution; use a reboiler to heat the tower bottom of the absorption tower, extract ammonia-containing gaseous substances from the top of the abso...

Embodiment 2

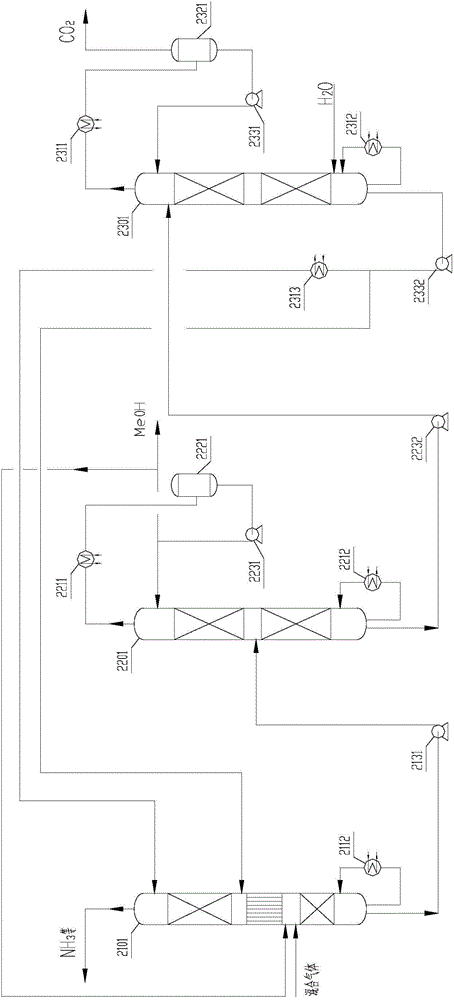

[0048] The second embodiment of the present invention relates to a specific method and device for separating ammonia and carbon dioxide. as attached figure 2 As shown: the device for separating ammonia and carbon dioxide in this embodiment includes an absorption tower 2101, an absorption tower reboiler 2112, an absorption tower bottom discharge pump 2131, a recovery tower 2201, a recovery tower reboiler 2212, and a recovery tower condenser 2211, recovery tower reflux tank 2221, recovery tower reflux pump 2231, recovery tower tank discharge pump 2232, desorption tower 2301, desorption tower reboiler 2312, desorption tower condenser 2311, desorption tower reflux tank 2321, desorption tower reflux pump 2331, lean liquid circulating pump 2332, desorption tower kettle discharge cooler 2313.

[0049] In the lower part of the absorption tower 2101, there is a gas-phase feed inlet for the mixed gas to enter, in the upper end and middle part of the absorption tower 2101, there are ab...

Embodiment 3

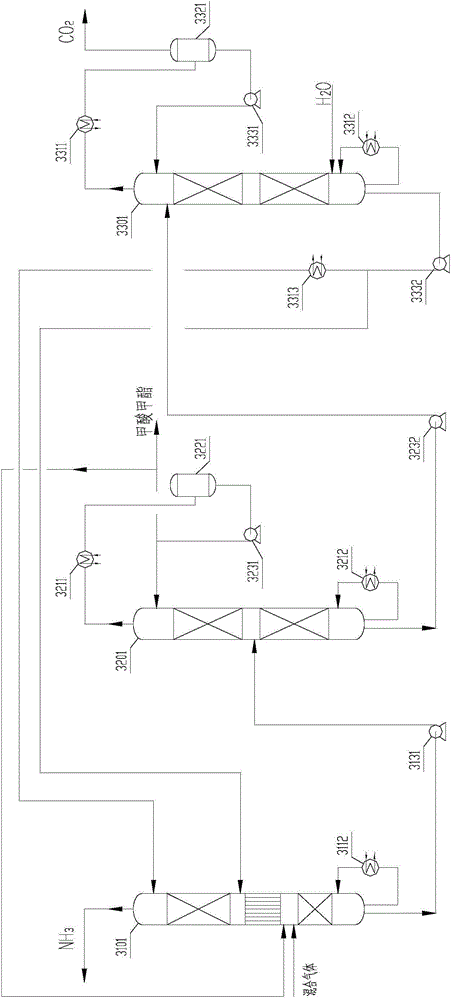

[0055] The schematic diagram of the separation device involved in the third embodiment of the present invention is as attached image 3 As shown, the ammonia and carbon dioxide separation device of this embodiment is the same as that of Embodiment 2. The difference between the separation method of this embodiment and Embodiment 2 is that the mixed gas to be separated in this embodiment contains ammonia and carbon dioxide, but does not contain It can be used as a low boiler to participate in the components of the separation reaction. In addition, in this embodiment, methyl formate is selected as the low boiler. Specifically the separation method of the present embodiment is as follows:

[0056] The mixed gas of ammonia and carbon dioxide is sent to the middle and lower part of the absorption tower 3101. The absorption tower 3101 is a packed tower with an operating pressure of 0.2 MPa (A). The mass-liquid-gas ratio of the absorbent to the mixed gas is 3:1; the total alkalinity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com