High-reliability spraying machine for automobile assembly line

An assembly line and reliability technology, applied in the direction of spraying devices, etc., can solve the problems of not providing high-reliability spraying machinery for automobile assembly lines, breakage at spraying, etc., and achieve the effect of reducing cleaning cost, uniform distribution, and improving filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

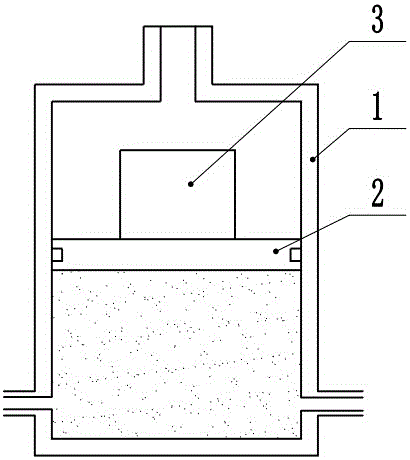

[0025] Such as figure 1 , a high-reliability spraying machine for an automobile assembly line, comprising a six-axis articulated robot and a spray gun installed at the end of the six-axis articulated robot, the spray gun is connected with a mixing device through a pressure maintaining device;

[0026] The pressure maintaining device includes a cylindrical body 1, the body 1 has a cylindrical inner cavity, and an opening communicating with the paint inner cavity is arranged above the body 1, and a floating plate 2 is arranged in the body 1 to The inner cavity is divided into two parts, the upper cavity and the lower cavity for storing paint. The floating plate 2 is in a transition fit with the inner cavity, and a sealing device is provided at the joint between the floating plate 2 and the inner cavity. The sealing device is Star seal;

[0027] A lead b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com