A laser surface processing method and system

A surface processing and laser technology, used in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of inability to dynamically adjust parameters, single effect style, etc., to reduce processing costs, improve system value, and avoid breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

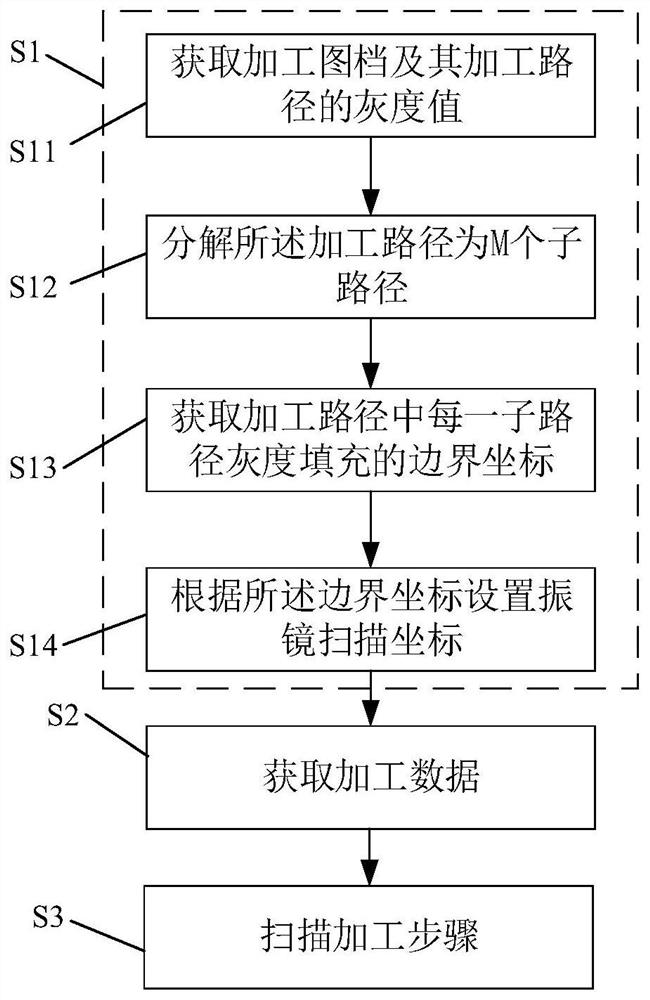

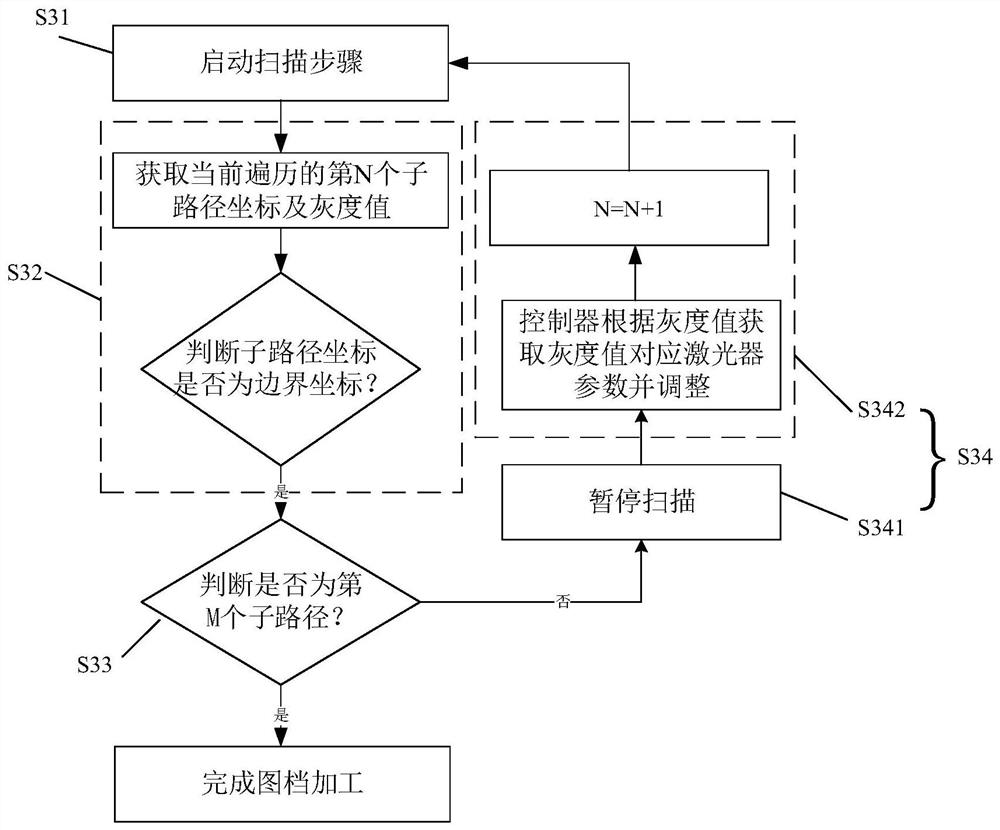

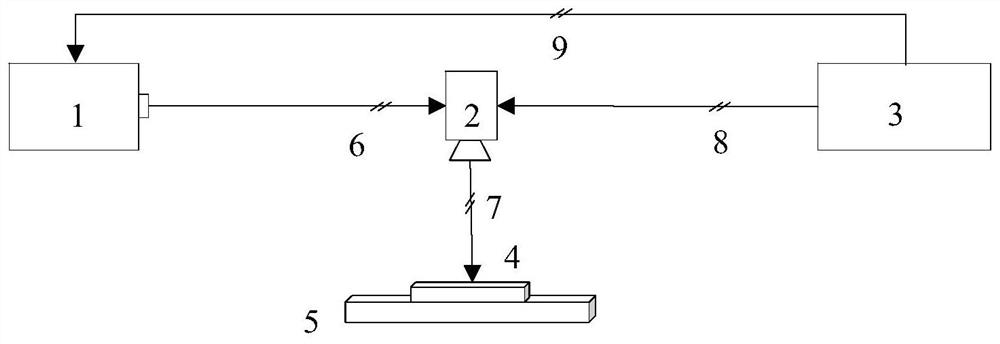

[0050] on the one hand, figure 1 It is a schematic schematic diagram of the preferred flow of the embodiment of the present invention, figure 2 It is a schematic flow chart of the preferred scanning processing steps in the embodiment of the present invention, refer to Figure 1-2 As shown, the present invention discloses a laser surface processing method, comprising:

[0051] The processing map file decomposition step S1 is to obtain the processing map file and decompose the processing path of the processing map file into a plurality of sub-paths according to the gray value, and obtain the gray-scale filled boundary coordinates of each sub-path, and at the same time set the vibration value according to the boundary coordinates. mirror scan coordinates;

[0052] The step S2 of acquiring the processing data is used for the grayscale laser parameter index table in the processing drawing file, wherein the grayscale laser parameter index table is established when the processing ...

specific Embodiment 2

[0073] Only the differences between this embodiment and the specific embodiment 1 will be described below, and the similarities will not be repeated.

[0074] This embodiment considers that in practical applications, the laser cannot completely correspond to all grayscale values, and the value range of the grayscale values is (0, 249), so as to further reduce the amount of data in the processing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com