Four-axis synchronous accurate-torque fastening equipment for bolts

A bolt and precise technology, which is applied in the field of automation equipment for precise torque fastening connection, can solve problems such as inconsistent bolt locking torque, unstable bolt connection torque, lack of torque acquisition system, etc., to ensure safety and reliability, The effect of easing the assembly process and ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

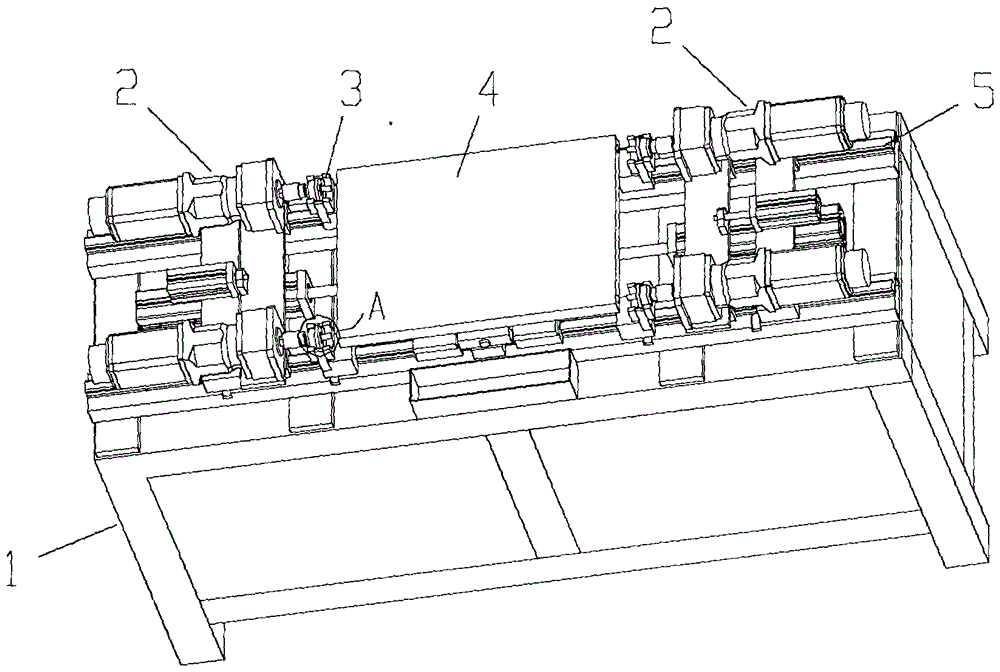

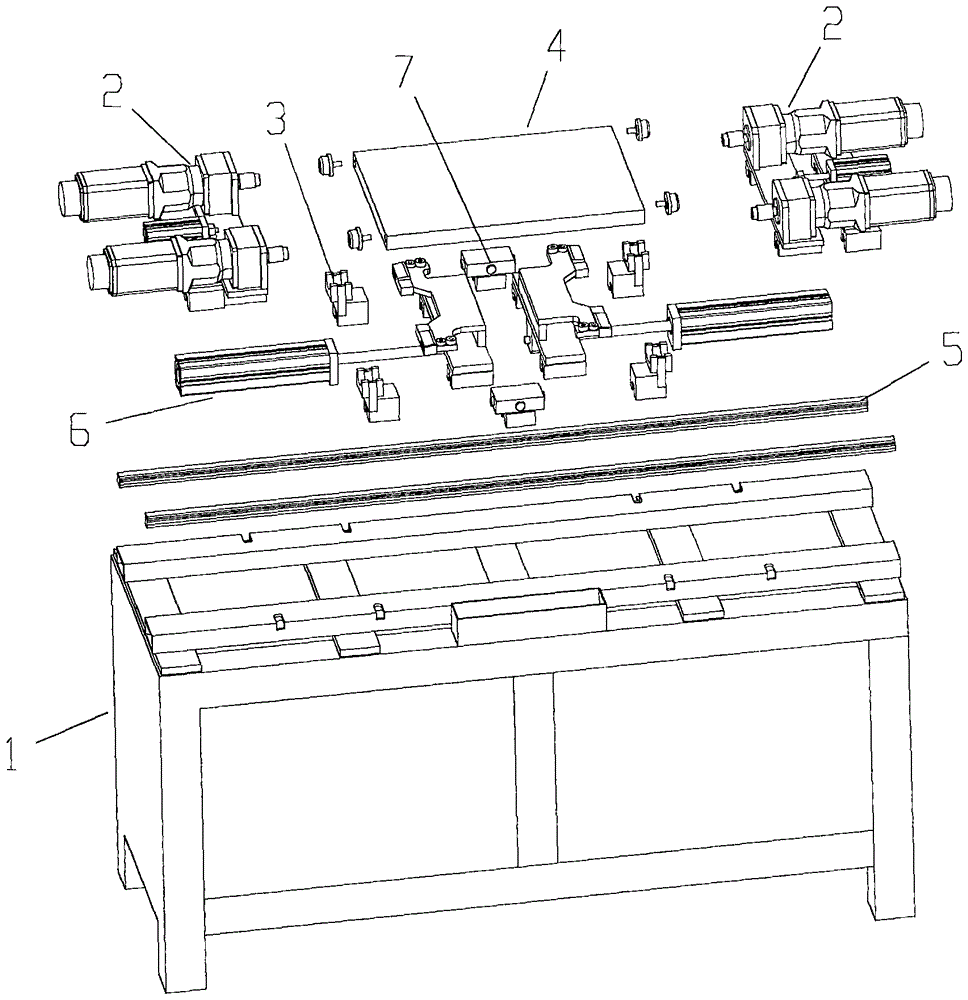

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, a four-axis synchronous bolt precision torque fastening equipment is provided, which can be installed on an industrial assembly line to fasten rollers and bolts to the equipment to achieve precise torque during tightening to ensure the safety of threaded connections. Reliable while increasing assembly efficiency and precision.

[0030] In this embodiment, taking the fastening of rollers and bolts to a large iron plate as an example, the working process and principle of the four-axis synchronous bolt precision torque fastening equipment are described.

[0031] The structure of the components to be assembled is first described below.

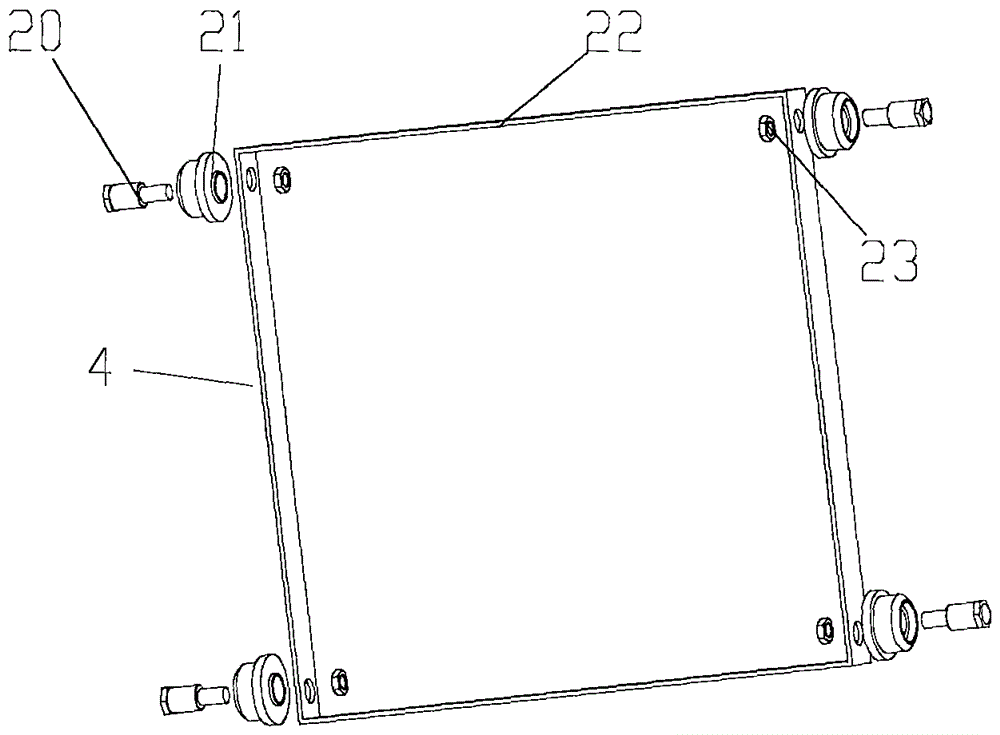

[0032] image 3 It is a schematic diagram of the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com