High-precision elastic barrel clamp fixing device

A technology of elastic collet and fixing device, applied in the direction of positioning device, clamping, feeding device, etc., can solve the problems of failing to meet the requirements of assembly accuracy, unreasonable fixing structure, etc., to improve service life, ensure high-speed dynamic accuracy, The effect of eliminating wind resistance and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

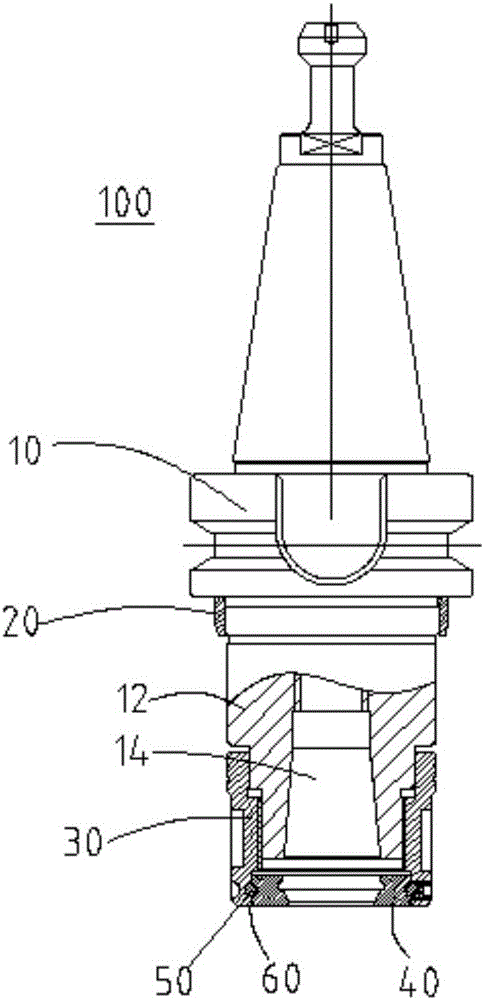

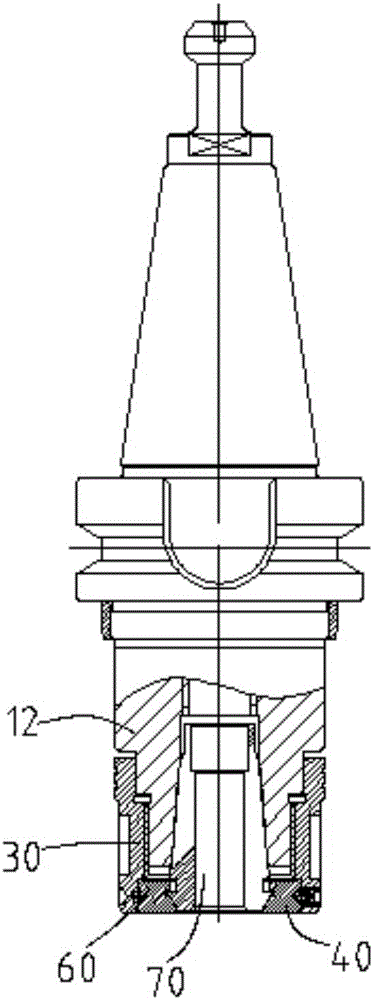

[0024] Such as Figure 1 to Figure 2 The illustrated high-precision elastic collet fixing device 100 is used to fix a high-precision elastic collet 70. The high-precision elastic collet fixing device 100 includes a first fixing member 10, a balance ring 20, and a locking device. Piece 30, a card position piece 40 and several rolling pieces 50.

[0025] The first fixing member 10 includes a positioning shaft 12. The first fixing member 10 is further provided with a mounting hole 14. The mounting hole 14 is provided in the positioning shaft 12. In one embodiment, the mounting hole 14 is a tapered hole. In one embodiment, the first fixing member 10 is a knife handle. The balance ring 20 is made of aviation aluminum alloy material.

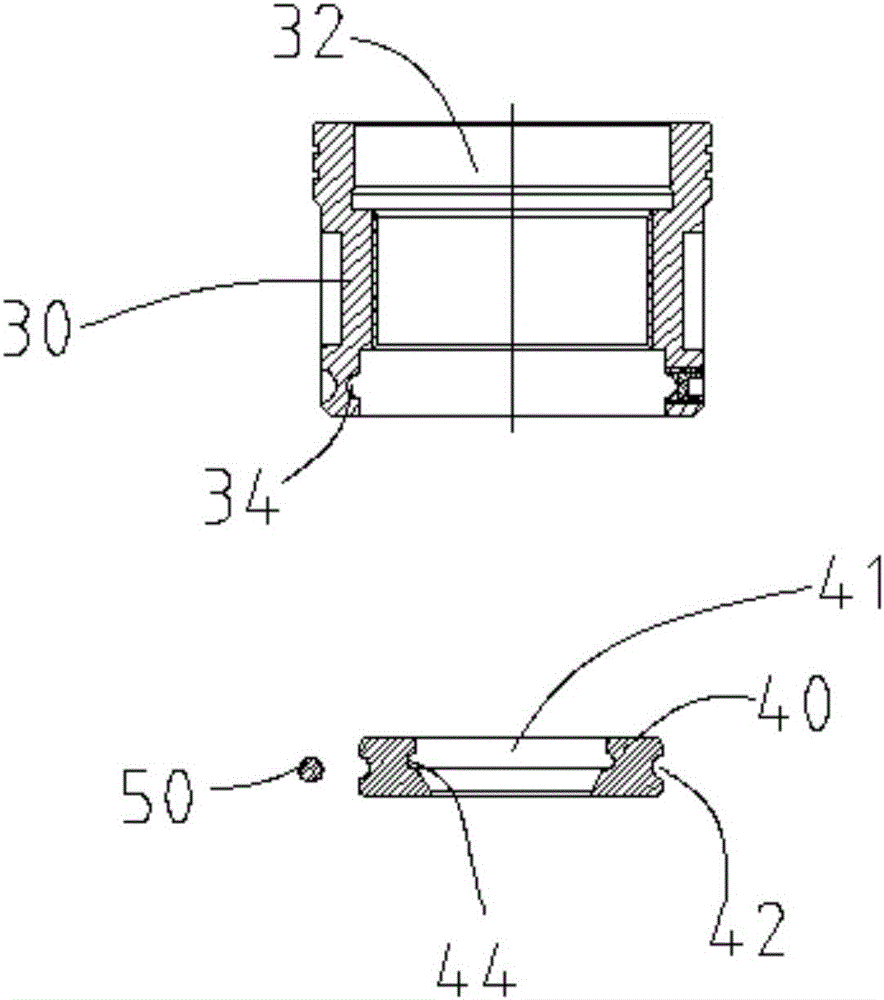

[0026] The locking member 30 is provided with a positioning hole 32 and an outer race 34. In one embodiment, the outer race 34 is generally annular. The retaining member 40 is provided with a clamping hole 41, an inner race 42 and a receiving groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com