Charging device for production of firework in unmanned workshop

A technology for fireworks and workshops, which is applied in the field of drug filling devices for fireworks production in unmanned workshops. It can solve the problems of unstable fireworks display effects, inability to form large-scale production, and high production costs, so as to reduce transportation risks, avoid material powder residue, The effect of a low risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

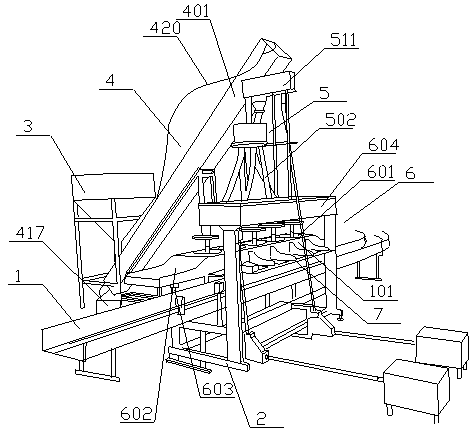

[0039] combine Figure 1-Figure 9 Shown is a filling device for fireworks production in an unmanned workshop. The filling device is erected on both sides of the fireworks production track 1, and includes a frame 2, a filling hopper 3, a feeding mechanism 4, a material distribution mechanism 5, a filling mechanism 7 and a general control The general controller is used to coordinate and control the intelligent control among various institutions.

[0040] The rack 2 is arranged under the track 1;

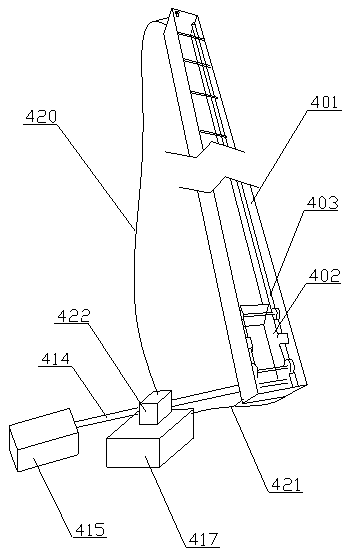

[0041] The filling hopper 3 is arranged directly above the feeding end of the feeding mechanism 4;

[0042] The conveying mechanism 4 is set up inclined, the lower end is the feed end, the upper end is the discharge end, and the discharge end is provided with a discharge port corresponding to the feed port of the distribution mechanism 5;

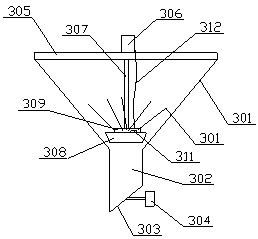

[0043] The material distributing mechanism 5 is provided with a first homogenizer 501, and several feeding pipes 502 are arranged below the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com