Grinding machine

A grinding machine and grinding technology, which is applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of low manual grinding accuracy, achieve high grinding accuracy, and ensure repair The effect of grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] example, see Figure 1 to Figure 5

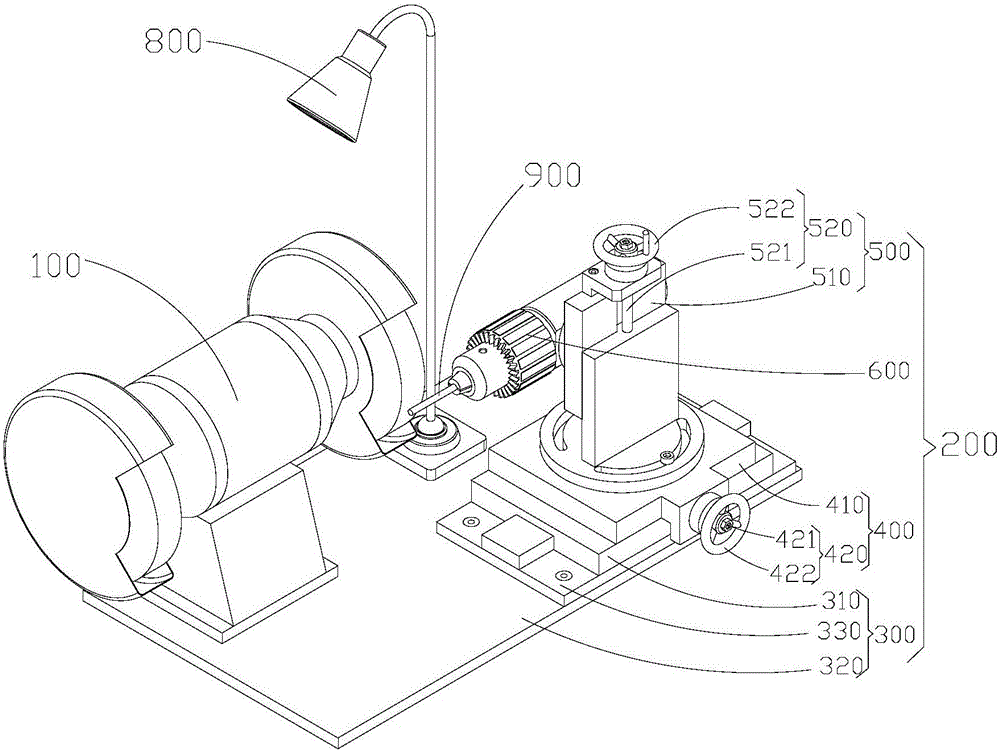

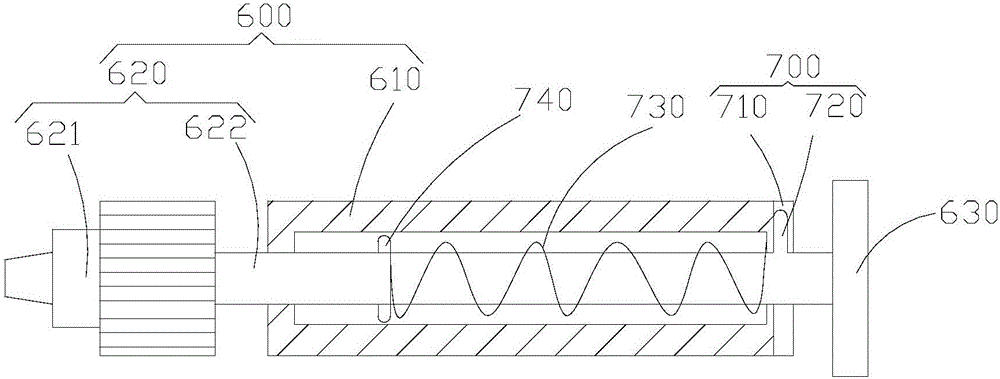

[0036] like figure 1 As shown, a grinding machine provided in this embodiment includes a grinding device 100 and a feeding device 200. The feeding device 200 includes a lateral feeding device 300, a longitudinal adjusting device 400, a vertical adjusting device 500 and a clamping device 600.

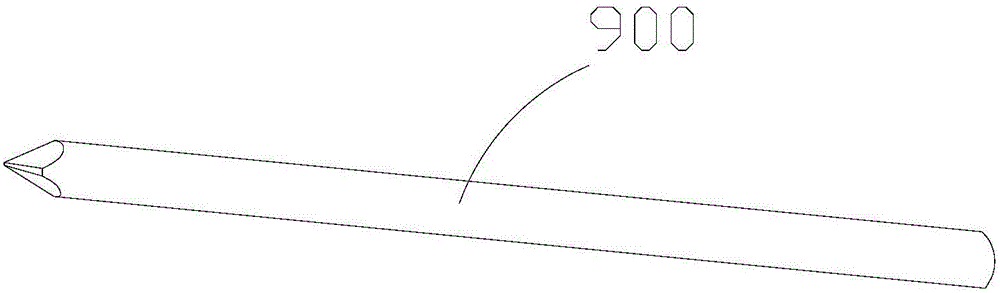

[0037] Wherein, the grinding device 100 is an existing device, such as a grinder, which can grind the tool to be ground, which is not repeated here. In this embodiment, as figure 2 As shown, the tool to be ground is a multi-faceted drill bit 900, that is, the drill bit 900 has multiple cutting surfaces.

[0038] The transverse feeding device 300 includes a base 320 and a first sliding block 310 . The first sliding block 310 is slidably connected to the base 320 , and the grinding device 100 is fixed on the base 320 . The base 320 plays the role of connecting the grinding device 100 and the feeding device 200, and its shape, structure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com