Electric power-assisted braking system with composite functions

A technology of electric power boosting and braking systems, applied in the field of vehicle engineering, can solve the problems of failure protection capability, complex structure, high manufacturing cost of brake-by-wire systems, etc., and achieve good matching with smart cars, small system pressure fluctuations, and high pressure regulation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

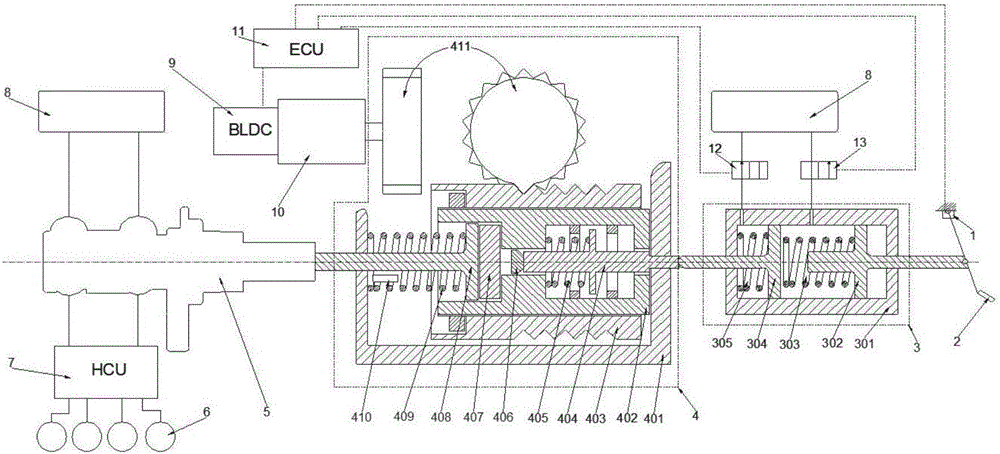

[0026] Such as figure 1 As shown, the present invention discloses an electric power-assisted braking system with compound functions, which includes a brake pedal displacement sensor 1, a brake pedal 2, a pedal stroke simulator 3, an electric power assist assembly 4, a master cylinder 5, Wheel cylinder 6, hydraulic control unit 7, liquid storage tank 8, motor 9, deceleration and torque increasing mechanism 10, electronic control unit 11, normally open solenoid valve 12, normally closed solenoid valve 13 and other sensors 14 on the vehicle, wherein the pedal stroke simulation The device 3 comprises a pedal stroke simulator housing 301, a front piston 302, a front piston return spring 303, a rear piston 304, and a rear piston return spring 305. Among them, the electric booster assembly 4 includes an electric booster assembly housing 401, a sleeve 402, a rack 403, a booster assembly push rod 404, a push rod return spring 405, a buffer block 406, a reaction disc 407, and a master c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com