Antitheft lock device

An anti-theft lock, a pair of technology, applied in the device to prevent theft of bicycles, transportation and packaging, bicycle accessories, etc., can solve the problems of illegal copying of electronic certificates, installation position restrictions, complicated use process, etc., to achieve large deformation and deformation accuracy High, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

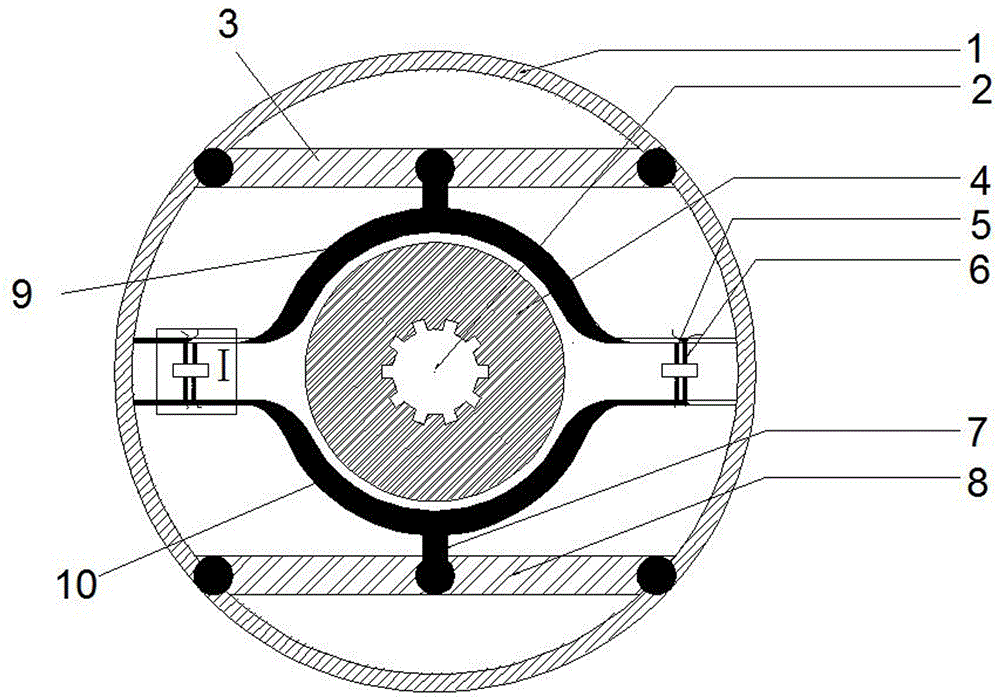

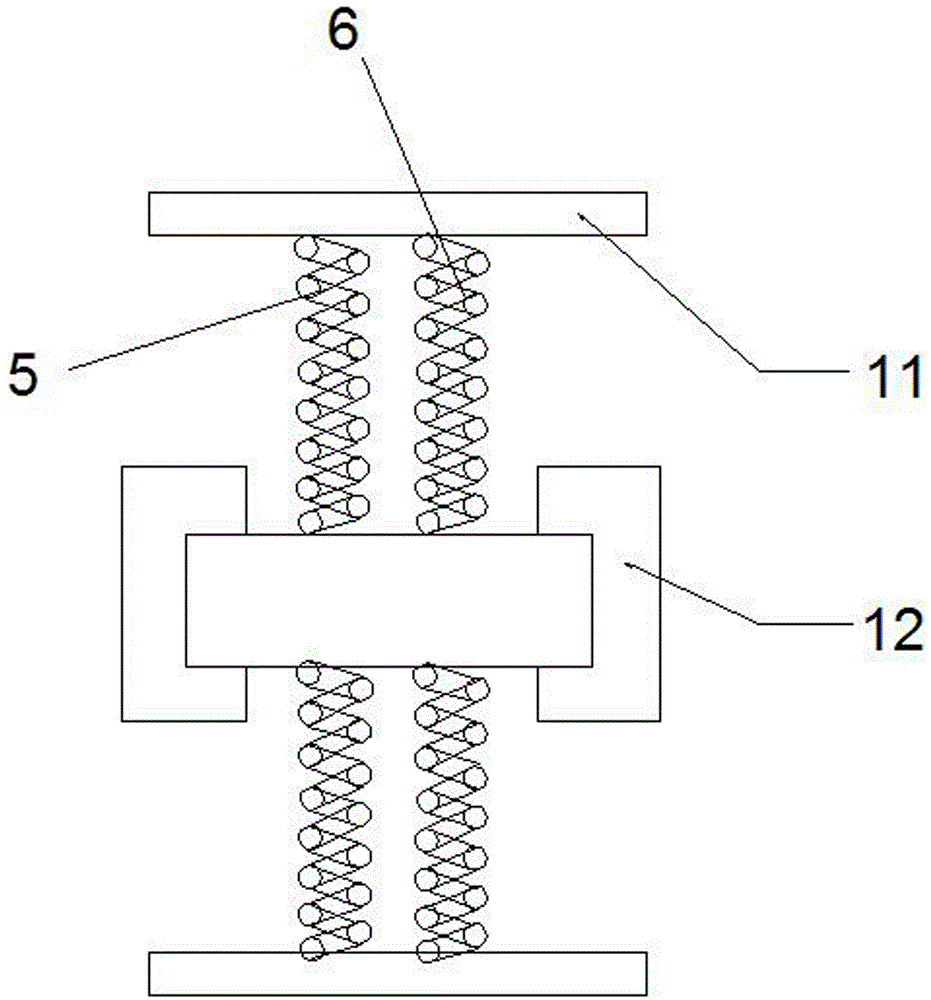

[0019] Example 1, see figure 1 with figure 2 , An anti-theft lock device, which includes a circular support frame 1 and a power supply. A pair of beams are symmetrically provided at the front and rear ends of the circular support frame 1, namely an upper beam 3 and a lower beam 8. The upper beam 3 and the lower beam A pair of brake pads are elastically connected between the beams 8. The brake pads are divided into an upper brake pad 9 and a lower brake pad 10. A set of shape memory alloy springs are respectively arranged between the two corresponding sides of the upper brake pad 9 and the lower brake pad 10 Each group of shape memory alloy springs includes a one-way heat-shrinkable spring 5 and a two-way heat-stretching and cold-shrinking spring 6. In the two groups of shape memory alloy springs, the circuit of the one-way heat-shrinking spring 5 and the two-way heat-stretching The circuits of the cold-shrinkable spring 6 are connected in series with each other through wires, ...

Embodiment 2

[0022] Example 2; see figure 1 with figure 2 , The lower brake pad 10 is fixed on the fixed beam 8 with six fixed springs 7, and both ends of the beam are fixed on the circular support frame 1 by the fixing bolts 3. The circular support frame 1 is screwed and fixed on the wheel hub. Keep a certain gap between the brake pad and the rotating disc 4; the rotating disc 4 and the wheel hub are respectively sleeved on the rotating shaft 2, and the radius of the rotating disc 4 is slightly smaller than the radius of the lower brake pad 10.

[0023] The lower brake pad 10 is semi-elliptical and elastic. Under the deformation of the shape memory alloy spring, the lower brake pad 10 is driven to move, and the rotating disc 4 is slowly held tightly until it locks. The action part of the lower brake pad 10 is mainly half On both sides of the ellipse, the top of the lower brake pad 10 is fixed, so in actual action, a part of the top is an invalid part, which is only used to fix the entire lo...

Embodiment 3

[0024] Example 3; such as figure 2 As shown, the one-way heat-shrinkable spring 5 and the double-way heat-stretching and cold-shrinking spring 6 and the upper and lower brake pads 11, 12 are provided with baffles 11 at the junctions. The baffles 11 are made of insulating materials. The upper brake pad and the lower brake pad are connected as an integral structure; the circuit of the one-way heat-shrinkable spring 5 and the circuit of the two-way heat-stretching and cold-shrinking spring 6 are connected to the power supply through a brake switch and a transformer. The one-way heat-shrinkable spring 5 and the double-way heat-stretching and cold-shrinking spring 6 share a brake switch, and the brake switch has a single-pole double-throw property. The brake switch adopts a double switch, and the circuit of the one-way heat-shrinkable spring 5 and the circuit of the two-way heat-stretching and cold-shrinking spring 6 are respectively connected to both ends of the double switch.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com